No More Loss Of Containers At Sea With New Vessel Response Forecasting System

The variety of containers delivered mixed-up has actually expanded approximately significantly over the previous years, and also today’s container lugging capability for the international container vessel fleet has actually exceeded 20 million TEU.

The variety of containers being moved by water is approximated to be 6 to 7 million at any type of offered time. A minimal variety of these containers never ever get to the location port.

Exact numbers are hard to evaluate, however the overall variety of containers shed mixed-up is approximated to be approximately 1,500 annually. Most of these losses are related to significant events where a a great deal of containers are shed in a solitary case. However, for a lot of events, simply a handful of containers have actually diminished the vessel.

Containers shed mixed-up might have serious navigational safety and security effects when left afloat at the sea surface area or at the seafloor in superficial waters. Moreover, the ecological influence can be big particularly when unsafe freights are moved.

Image Credits: abb.com

Historical events have actually brought about a series of feedbacks from the sector, and also a number of safety nets are executed at the worldwide degree. Noticeable interest has actually been paid to container protecting techniques and also dimension of container weights, where extra policies are executed to lower the threats.

Most of the container losses are related to damaging climate condition, generally in mix with various other variables. If the ship is stagnating in the waves, a container will not diminish, however when the ship is revealed to harsh weather condition, each specific container goes through pressures on the container and also its lashings and also can result in failing of the lashing or the collapse of the framework of the container. In such problems, also if a container is not shed mixed-up, the freight inside the container may experience significant damages.

Forces on a container belong to the mass and also velocities of the container. Mass or weight can be determined quickly and also will not alter throughout the trip, however the velocities differ frequently. We identify mostly in between upright elements and also side elements of the tons and also velocities. In our context, upright and also side is about the vessel. Too high upright tons might result in architectural failing of a container. Containers can endure compressive and also shear pressures as much as a specific created restriction. The container at the most affordable rate has the biggest threat to collapse because of these tons generated by the weight of containers in addition to it.

Lateral tons might result in high pressures in the lashings or container edge installations and also present the threat for the container to topple if a lashing falls short. Containers at the sides and also near to the bow or strict of the vessel are a lot more revealed to this threat.

Image Credits: abb.com

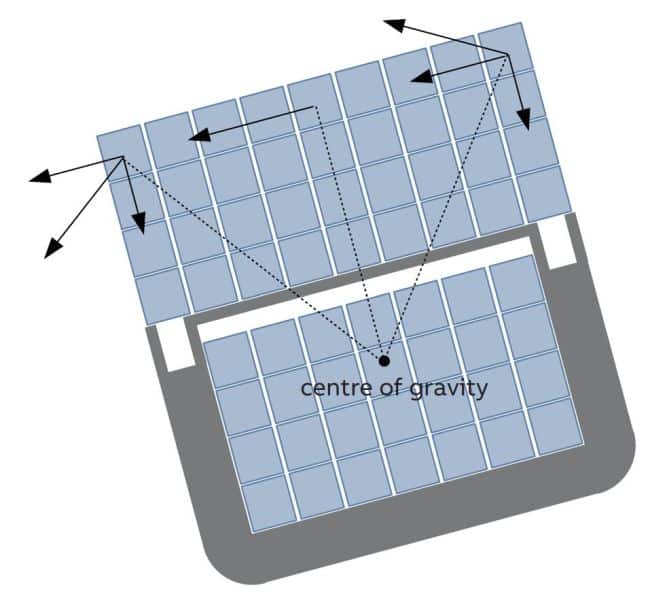

The 2nd by-product of roll activity relative to time is the angular velocity. The additionally far from the axis of turning the container is, the bigger the velocities because of roll activity. Without combining to various other activities like persuade and also yaw, the axis of turning goes to the center of gravity of the vessel. Acceleration is biggest for the container at the highest possible rate and also near the sides of the vessel. The instructions of the velocity is vertical to the aircraft specified by the axis of turning and also the setting of the container. As a repercussion, the container with the highest possible side lots because of roll velocity goes to the highest possible rate and also– depending upon the range to the center of gravity– go to the centerline or beside the vessel. Loads because of roll velocity are shown in Figure 1.

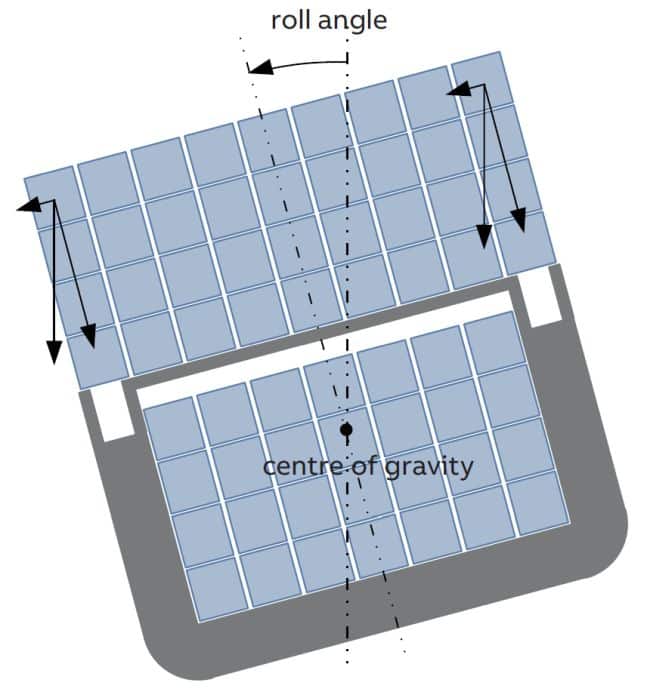

Another payment to the pressures on the container is because of gravity. Gravity has a significant influence on the upright tons however additionally add to the side tons when the vessel is inclined. Vertical and also side elements of gravitation are shown in Figure 2.

Figure 1. Contribution to the tons on containers because of velocities in pure roll activity, and also their side and also upright elements about the ship.

Figure 1. Contribution to the tons on containers because of velocities in pure roll activity, and also their side and also upright elements about the ship|Image Credits: abb.com

The 2 payments to the velocities– gravity and also roll velocity– amount to the overall velocity applied on the container. In the situation of normal roll activity, both elements differ with time and also have their extremes for the side velocity at the exact same minute in time. Containers at placements greater than the vessels center of gravity will certainly have the elements intensified. The size of the payment from gravity is direct with the roll amplitude, however the size of the payment from roll velocity is direct with the roll amplitude, as well as additionally square with the round regularity and also thus square with the duration of roll activity.

The scenario comes to be far more hard to recognize if activities in all 6 levels of flexibility are thought about at the exact same time. Not simply the activity amplitude is very important however additionally the family member stage change of the various activity elements. Besides this, the practices of the vessel depends upon the packing problem and also particularly transverse security.

Accelerations are simple to determine with accelerometers. Velocity after that adheres to from the assimilation of the velocity with time. Further assimilation with time will certainly result in the activity of the vessel. If the velocities are determined in all 6 levels of activity– that is 3 translations and also 3 turnings– and also the framework of the vessel is inflexible, after that the velocity and also activity of every area on the vessel can be computed from the determined velocities. In fact, vessels are not inflexible, and also the vessels framework does flex because of the differing tons on the hull. Also, a minimal measuring precision presents unpredictability in the estimations. However, when velocities are determined at a minimum of 3 areas well dispersed over the vessel these restrictions can be gotten over. Measuring and also keeping an eye on the velocities is called activity surveillance. Motion surveillance might be made use of as a basis to evaluate the threat of shedding containers because of too much velocities in the wave problems at the time of dimension.

Figure 2. Contribution to the tons on containers because of gravity for a heeled ship, and also their side and also upright elements about the ship|Image Credits: abb.com

Monitoring vessel activities make it feasible to fetch historic time collection of velocities for any type of area aboard. This is beneficial details when exploring an event. This details is additionally beneficial throughout day-to-day procedures. Is the present scenario still appropriate or essential for the containers and also lashings? The actual worth for risk-free procedure of the vessel comes when the vessel activities and also velocity degrees are forecasted for the future and also thought about when choosing for the procedure of the vessel.

Weather projections consist of the wave problems and also are beneficial details for the master to prevent dangerous problems. Such details can assist prevent sea locations where too much vessel activities are most likely to take place. However, the analysis of a wave projection with the objective to lower the degree of velocities at the container areas is a job of expensive intricacy to do by hand. Avoiding locations where the waves are the highest possible might not work if the circulation of wave durations and also wave instructions about the vessel have a lot more influence on the velocity degrees than the elevation of the waves. Automation can assist and also convert the projection wave problems right into projection vessel activities. Knowledge of exactly how the vessel reacts to waves is necessary to do this and also concepts have actually been created to prepare such details with adequate precision for onboard usage. For varieties of wave instructions, wave durations and also wave elevations in mix with an array in vessel rates and also packing problems the feedback of the vessel in the waves is computed and also kept in a data source.

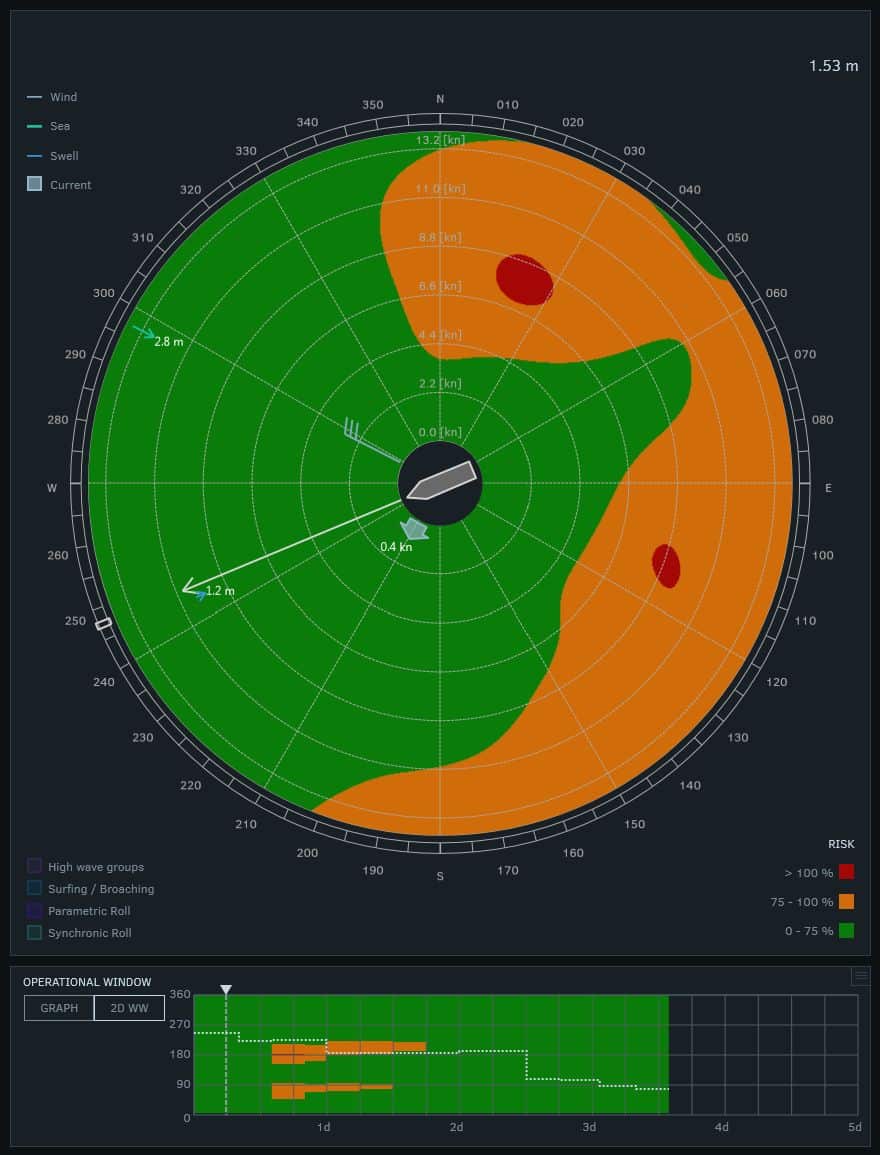

Vessel feedback projecting is the computerized procedure to convert the wave projection right into a projection for the activities of the vessel. ABB Ability ™ Marine Advisory System– OCTOPUS is ABB’s remedy for onboard usage where vessel feedback projecting is installed in the system. ABB Ability ™ Marine Advisory System– OCTOPUS does offer details concerning the present scenario, as well as additionally assists to determine the threats connected to the activities when transforming heading or transforming the rate of the ship. An instance of an onboard display screen is shown in Figure 3. Motions like roll and also pitch are computed for the complete series of headings and also ship rates and also are compared to a limitation. Red locations show problems where a minimum of among the offered limitations is surpassed. Amber locations show problems where activities serve, however near to the restriction.

Figure 3. On- board display screen of forecasted activity feedbacks for all headings and also ship rates|Image Credits: abb.com

Vessel feedback projecting is a help to decision-making for procedures mixed-up and also prevails method for intricate overseas procedures. Nowadays vessel feedback projecting is additionally presented in the container delivery sector with the objective to enhance the safety and security of the vessel, its staff and also the freight.

References

- Standing, R.G. Review of the duty of feedback projecting in decision-making for weather-sensitive overseas procedures.

- BMT Fluid Mechanics Research record 347, planned for Health and also Safety Executive.

Source: abb.com