Thordon Bearings stated Monday that its water-lubricated elastomeric polymer bearings have actually been mounted to well pumps aboard a concealed overseas oil system run by Abu Dhabi National Oil Company (ADNOC).

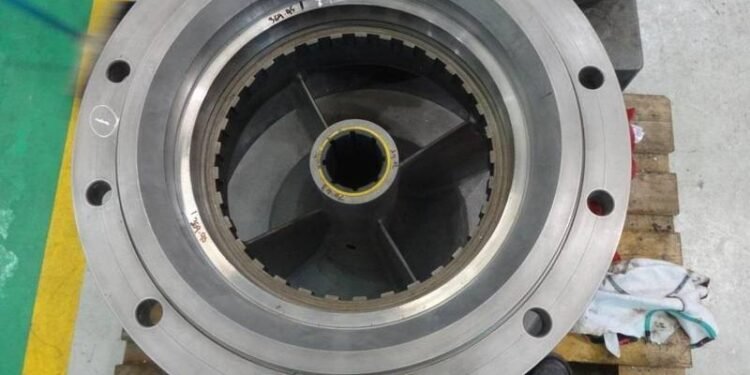

Five KSB three-stage blended circulation impeller-type pumps were each retrofitted with Thordon pump bearings – 13 SXL intermediate bearings, 4 Composite bearings and also a solitary SXL throttle bearing – changing the initial silicon carbide shrubs, the business stated.

Dubai- based design company Ocean Power International (OPI), Thordon’s licensed representative in the Middle East area, got the complete extent of supply straight from Thordon’s plant in Burlington, Canada, 4 weeks after putting the order.

“The problem with silicon carbide bearings is that they have a long lead time, and are brittle which means there is a risk of the bearings chipping and breaking. They are simply not as robust and are very expensive to replace,” stated Rafid Qureshi, Managing Director, OPI.

“By comparison, Thordon SXL and Composite bearings resolve the price and lead time issues, are very durable, and they are also more considerate to the environment as they don’t require lubricating oil or grease,” he said.

After OPI gathered all the parameters and reviewed the pump drawings, the Thordon bearings were delivered well within the requisite time frame, allowing KSB, the original equipment manufacturer (OEM), to carry out the retrofit installation work and commission the pumps in quick time, avoiding any rig downtime, Thordon Bearings said. ©Thordon Bearings

©Thordon Bearings

KSB Abu Dhabi has now refurbished all five pumps with the new Thordon bearings, the last of which was completed in August 2022. However, the company has been converting its pump bearings over to the Thordon polymer material over the course of the last 10 years.

Michal Belina, Mechanical Engineer, KSB Service, said: “The technical and engineering specifications of the bearings meet and exceed expectations. Compared to silicon carbide, which is typically used in these vertical pumps, Thordon’s products are not only more cost effective, but one of the biggest advantages is that they are easy to machine. They have excellent resistance to abrasion, even after a few years of operation the bearings have correct clearances. We are very satisfied with this product and our main factories in Germany are now using Thordon bearings in our new pumps.”

As the pump OEM, KSB has an agreement with ADNOC Offshore to fix and also upgrade the pumps, described Anupam Paul, Application Sales Manager -Gulf Region, OPI

“When the pumps are dismantled and come in for repair and refurbishment, KSB has only 10 to 14 days to do the repair. We have a good relationship with the company and a huge inventory of Thordon stock, so whatever size the customer asks us for, it’s on the shelf and ready to go.”

Given the long-lasting integrity of these installments given that the connection with Thordon Bearings started in 2011, Qureshi claims that in future, ADNOC will certainly remain to utilize Thordon’s bearings in any type of suitable pumps released on its systems.