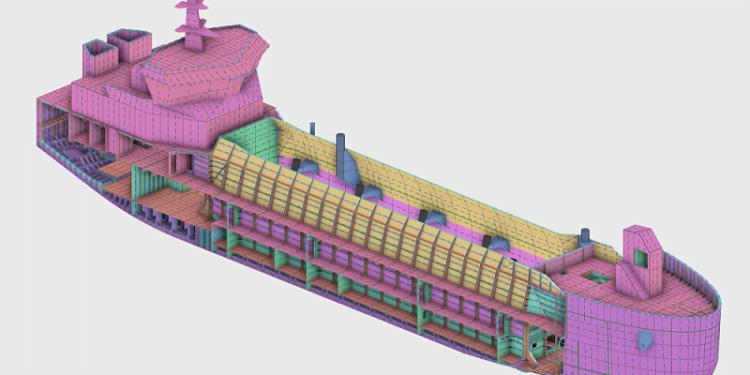

Classification culture Bureau Veritas has actually efficiently evaluated a 3D style of a 2500 m ³ receptacle dredger from Damen Shipyards, being an action to approving it authorization in concept. The pilot task for 3D model-based course authorization is implied to lead the way towards making use of 3 dimensional computer system layouts as guideline to accomplish course symbols for seagoing vessels.

Vessel steel hull Design assessment based upon 3D versions in alongside its category evaluation procedure has actually come to be feasible many thanks to the brand-new information exchange layout – OCX. The OCX is an open requirement that promotes information exchange of 3D ship versions for course authorization. This Open Class 3D Exchange requirement has actually been created by a consortium of software program firms consisting of NAPA as well as Aveva, along with category cultures consisting of DNV, Bureau Veritas as well asLloyds Register In close cooperation with Finnish software program designer NAPA as well as Bureau Veritas, Damen has actually offered the 3 dimensional style of their TSHD 2500 (Trailing Suction Hopper Dredger with 2500 m ³ receptacle capability). All the objective devices as defined for a customer had actually been incorporated right into this style. Bureau Veritas analyzed the steel hull framework to be solid sufficient as well as risk-free to SOLAS criteria, with every one of the hefty devices functional.

The OCX layout has actually been offered considering that 2022. First pilot tasks for partial layouts were completed in November in 2015. The task for the Damen Dredger with NAPA as well as Bureau Veritas is the very first full steel hull to accomplish course authorization by 3D style. Damen plans to use this authorization procedure with even more vessels, additionally in co-operation with course culture DNV as well as others.

Today’s ideal method is 2D technological illustrations stay a specific need when marine designers as well as shipyards send their hull layouts to category cultures, to guarantee they satisfy both Class as well as Statutory demands. After the course culture researches the illustrations, occasionally adjustments are called for. The developers take the statements from the illustrations as well as use them in the 3D design. Then the procedure repeats. Presenting the 3D versions to category cultures conserves a great deal of time as well as existing making blunders. Open information exchange requirement help with exchange of 3D ship versions for course authorization.

“Seeing the results of this first class approval for a vessel steel hull, we are certain that this is the way to go,” stated Managing Director Kasia Romantowska fromDamen Engineering Gdansk “Development time for the steel construction will be shorter thanks to class approval and us using 3D models only. We have more control over the technical risks embedded into a prototype vessel design process. It has been the first time that have we closed the 3D data exchange loop between parties. We expect to be able to save significant percent of design time when we integrate this way of working as a standard. The big benefit is the enhanced project team collaboration within the same, fully digital, transparent daily work context, applicable for designers and approval engineer at the same time.”

Romantowska stated much more demonstrator tasks for 3D design based course authorization get on the method.