Floating Production Storage and Offloading (FPSO) Vessels are invaluable for the offshore oil and gasoline trade, given their many benefits over conventional offshore oil platforms.

FPSOs are positioned near an offshore oil subject. Using FPSOs over pipelines implies that the FPSO Vessel might be moved to a different place when an oil subject has been exhausted.

FPSOs are constructed to resist the harshest circumstances and the deepest waters. They may regularly function for round 20 years and extra, proving cost-effective.

Fluids are collected from subsea reservoirs by way of pipes after which separated into pure gasoline, crude oil, water, and impurities within the manufacturing amenities situated on the FPSOs. Crude oil is saved in tanks and loaded into shuttle tankers for distribution or extra refining.

There is an elevated demand for brand new and transformed FPSOs, primarily as a result of lowering charge of recent onshore oil discoveries and technological enhancements which have enabled deepwater oil exploration in unprecedented depths.

FPSOs show useful in offshore oil areas that lack a pipeline infrastructure. They are important in distant areas the place constructing a pipeline community will not be potential attributable to prices or different causes.

Today, greater than 270 vessels are deployed as oil FPSOs globally.

However, on this article, we are going to have a look at the 5 Biggest FPSOs, their functioning and the engineering that makes them the very best among the many relaxation.

1. Egina FPSO

TotalEnergies Egina FPSO is the world’s largest floating manufacturing, storage, and offloading vessel by capability. It is located within the Egina oil subject, round 130 km off the Nigerian Coast, at a depth of over 1500 m.

It is alleged to be Total’s most formidable ultra-deep offshore undertaking, which additionally goals to spice up Nigeria’s industrial improvement and enhance its oil manufacturing.

The Egina Oil Field was found in 2003 and covers an space of roughly 500 sq. miles. It lies 200 km offshore from Harcourt Port at water depths between 1400 and 1700 m.

According to estimates, the sector has 550 million barrels of oil. Approval for growing it was given in 2016, and TotalEnergies began manufacturing from the Egina FPSO in 2018.

TotalEnergies operates it and has a 24% stake in partnership with CNOOC, NNPC, Sapetro and Petrobras.

Egina FPSO has a 100-m flare increase and an oil offloading terminal. It is designed to carry 2.3 million barrels of oil and connects to 44 subsea wells at a depth of 1600 m, producing 208,000 barrels of oil every single day.

It can also be linked to a subsea manufacturing system that features risers, 52 km of oil and water injection flowlines, 20 km of gasoline pipelines, 12 jumpers, and 80 km of subsea manifolds.

The FPSO weighs round 220,000 metric tonnes and is 330 m lengthy and 60 m broad, making it TotalEnergies’ biggest-ever FPSO. Egina’s topside modules have a gross dry weight of 47,500 tonnes and comfortably accommodate 200 working professionals.

Egina FPSO was constructed by Samsung Heavy Industries and native contractors in a specifically constructed shipyard in Nigeria. Six of the 18 modules have been constructed in Africa and built-in regionally, the primary time such an advanced undertaking was assembled in Africa.

TotalEnergies is repeatedly innovating Egina FPSO to satisfy the undertaking’s challenges. For occasion, the Vclay subsea manufacturing system gives extra detailed knowledge and a extra correct understanding of the reservoir and the positions of the wells.

Also, this undertaking has enhanced Nigeria’s infrastructure. A 500 m lengthy dock was constructed to assemble Egina, which will probably be used for different initiatives as soon as it has served this objective.

Today, Egina is chargeable for round 10% of Nigeria’s whole oil manufacturing, which has allowed Africa to host one of many world’s largest oil and gasoline initiatives.

2. Turritella FPSO

This Shell’s FPSO is positioned within the Stones subject, an offshore oil and gasoline undertaking within the U.S Gulf of Mexico. Turritella was designed specifically for this subject, which was found in 2005 and which Shell deliberate to develop in 2013.

The Turritella FPSO reached the Gulf of Mexico in 2016 and commenced operations from two subsea wells. Six have been added later, together with a multi-phase system to pump oil and gasoline from the seabed to the FPSO.

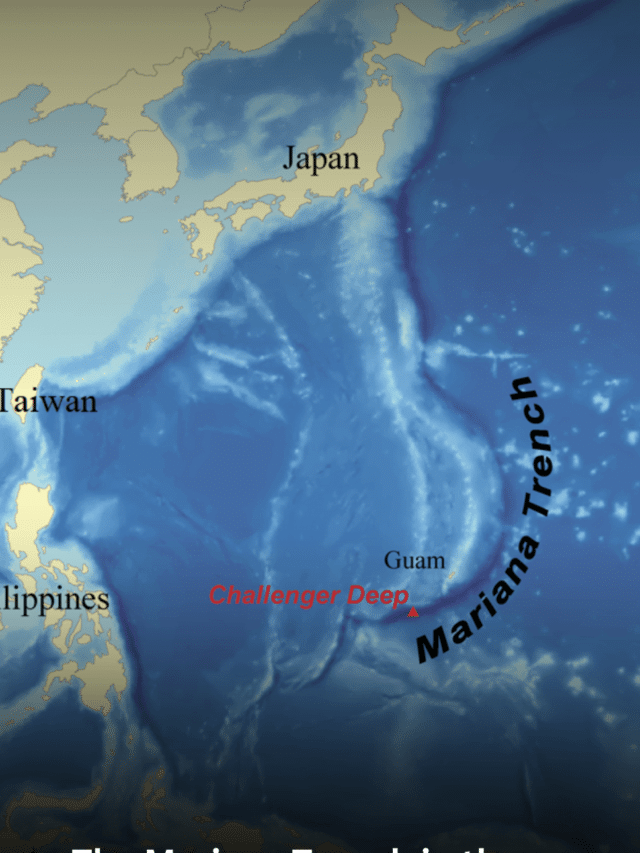

At its most capability, it will possibly produce round 50,000 barrels of oil day by day. Turritella FPSO capabilities in a 2900 m water depth, making it the deepest FPSO and the world’s deepest oil and gasoline manufacturing facility of any sort.

The Stones Field covers 8 blocks of the decrease tertiary geologic development, and the reservoirs lie roughly 7077 m beneath sea degree. The subject is taken into account to have over 2 billion barrels of oil equal.

SBM Offshore constructed the Turritella FPSO in Singapore. It was the primary FPSO for Shell and SBM Offshore to be put in within the Gulf of Mexico.

The undertaking was troublesome to implement and fraught with many challenges, equivalent to putting in and working subsea infrastructure and gear at substantial depths. The FPSO additionally needed to face the cruel climate of the Gulf of Mexico, which is thought for its hurricanes and violent storms.

Turritella FPSO was constructed with these hurdles in thoughts. So it was fitted with the most important disconnectable buoy on the earth to allow it to maneuver away in case of violent hurricanes and to attach later, permitting manufacturing to renew as rapidly as potential.

It additionally pioneered utilizing an in-line Mooring Connector, permitting it to readjust each mooring line pressure with out impacting any put in gadget. This innovation is now present in a number of different vessels.

It was additionally the primary to make use of Steel Lazy Wave Risers with a disconnectable buoy, which permits the FPSO to take care of stability by absorbing the affect of huge waves, growing manufacturing at excessive water depths.

3. Glen Lyon FPSO

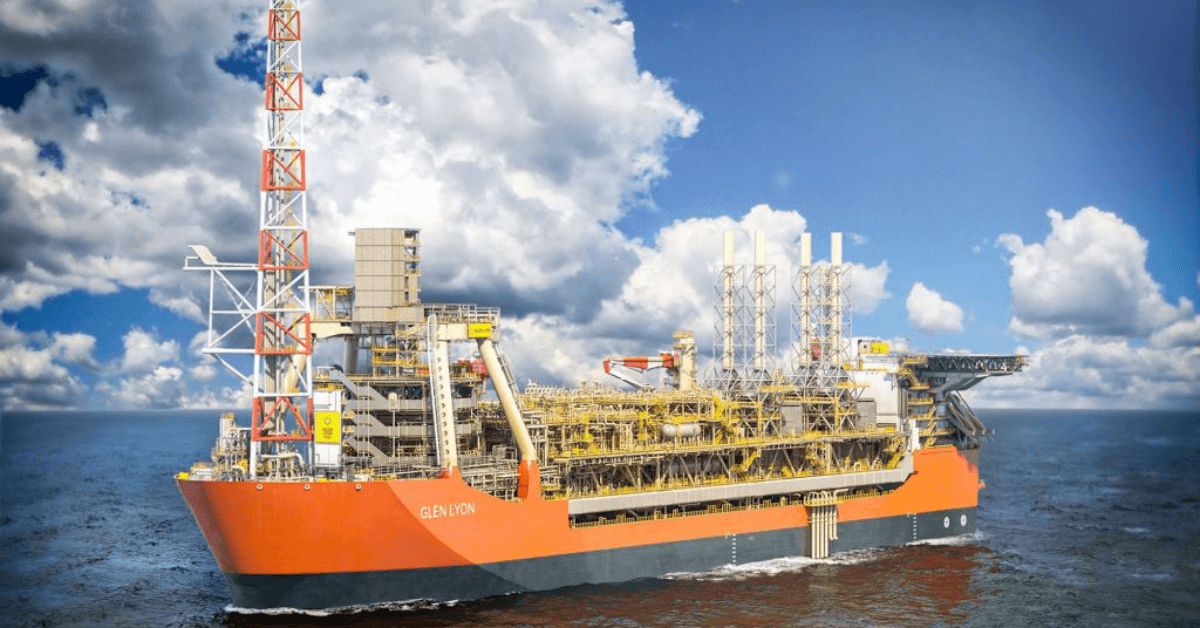

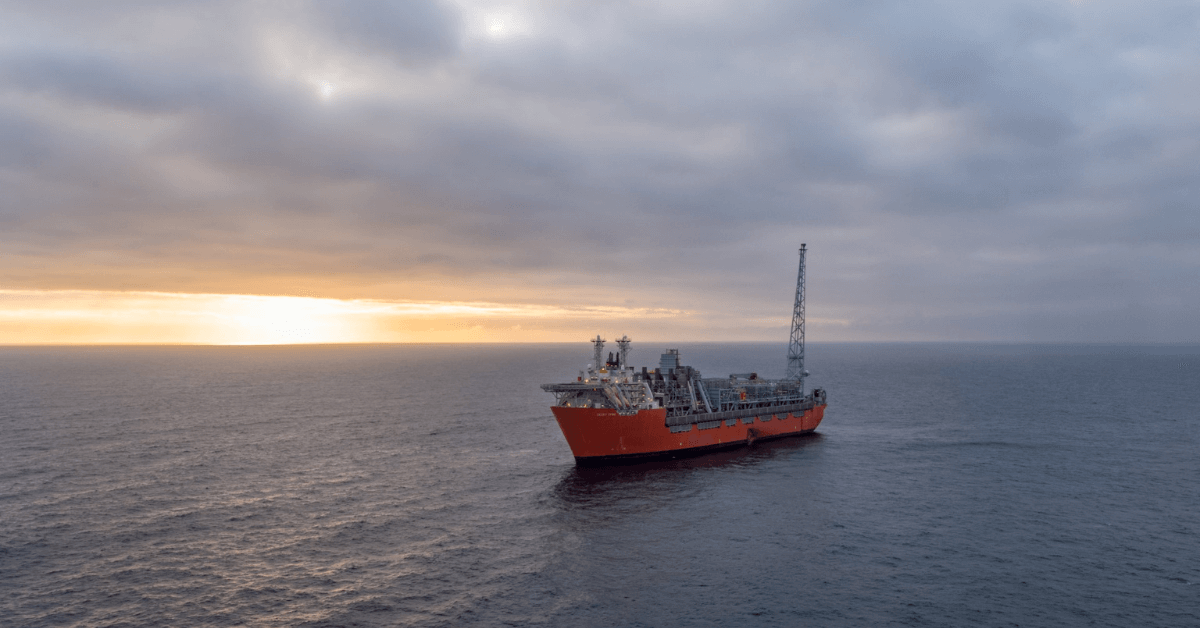

BP’s Glen Lyon FPSO can retailer 800,000 barrels of oil and course of and export 130,000 barrels of oil every single day. It can also be the most important harsh-water FPSO vessel on the earth, specifically constructed for BP’s redeveloped Quad 204 Project.

It includes extending the lifespan of the Schiehallion and close by Loyal fields within the North Sea, situated 175 km west of the Shetland Islands.

The fields had produced about 400 million barrels in 15 years, starting in 1998. Also, the sooner Schiehallion FPSO had to get replaced with a way more technologically superior counterpart because the operator believed extra could possibly be extracted from the oil fields.

The Quad 204 Project goals to increase the sector’s manufacturing life past 2035 and extract round 450 million barrels extra.

Glen Lyon was constructed by Hyundai Heavy Industries in South Korea and towed utilizing tugs to Norway after which to its vacation spot, the North Sea. It is 270 m lengthy and 52 m broad, weighing 100,000 tonnes, and may simply accommodate 140 individuals.

It is constructed for the tough North Sea circumstances and has superior seakeeping and long-term processing capability. It is anchored to the seabed by means of a turret mooring system and 20 strains, which run nearly a mile lengthy.

4. Skarv FPSO

Aker BP’s Skarv is one more huge floating facility with one of many largest offshore gasoline processing vegetation the place gasoline is processed earlier than it’s despatched to the Karsto plant in a greater than 800 km lengthy pipeline. Oil from the FPSO is offloaded on tankers.

Skarv Field was present in 1998 within the Norwegian Sea, 50 km south of the Arctic Circle. Construction started in 2008 on the Skarv FPSO to provide gasoline from the subsea wells. Like Glen Lyon, Skarv has been designed to function in harsh circumstances at water depths of 350 to 450 m.

The primary building befell in Korea, together with the 49,000-tonne hull, which measures 295 m lengthy and 51 m broad. A manufacturing module weighing 18,000 tonnes was additionally constructed, with a manufacturing capability of 85,000 barrels per day, 19 million sm3/d. Skarv FPSO has a storage capability of roughly 875,000 barrels.

Its turret, constructed in Singapore, weighs 7,500 tonnes. It is 77.4 m excessive, and its flare tower is 154.6 m above the bottom of the hull.

The Skarv subject started working in 2012, and the FPSO was linked to 12 manufacturing wells, 4 injection wells, and 5 subsea templates. According to estimates, the sector’s manufacturing life is 25 years.

5. Arco Ardjuna FPSO

Arco Ardjuna FPSO was in-built 1973, which makes it over 45 years outdated. Yet it’s nonetheless operational within the Java Sea. It was designed at a time when FPSOs weren’t as frequent as they’re now.

The FPSO was constructed for the Ardjuna Oil Field within the West Java Sea, 95 km from Jakarta, Indonesia. It spand 8300 km2 and has 314 producing wells.

Initially, ARCO operated it, however later, BP West Java got here into the image. Today, Arco Ardjuna is operated by the government-owned Oil and Gas Company Pertamina.

The FPSO was in-built Japan on the MHI Nagasaki Shipyard & Engine Works.

It weighed 53,734 tonnes, making it one of many largest ships on the earth when it was being constructed. Given its age, the truth that it nonetheless operates in the present day is at least an achievement. It was lately linked to pipelines tied to Pertamina’s KLB Pavilion in YY subject off the Indonesian coast.

Conclusion

With every passing 12 months, we witness the emergence of recent applied sciences within the maritime sector. Ships are getting greater, higher, and extra superior, and so are FPSO Vessels, whose existence is significant for the offshore oil and gasoline sector. FPSO vessels provide many benefits and are cost-effective since they are often moved to a different location.

They function within the harshest climate circumstances, from the Gulf of Mexico to the North Sea and the Norwegian Sea. They are marvels of engineering and testaments to human ingenuity.

In the quickly increasing world vitality panorama, the most important FPSO vessels assist meet the wants of the worldwide market and assist transfer the offshore oil and gasoline trade in the direction of a greener and extra environment friendly future.

You may also prefer to read-

- What is FPSO (Floating Production Storage and Offloading) System?

- Munin – The Award Winning FPSO (Floating, Production, Storage and Offloading) Ship

- Maersk’s Floating, Production, Storage and Offloading Systems (FPSOs): The Fantastic Four

- The LNG Supply Chain Explained

- 14 Types of Ships with Dynamic Positioning System

Disclaimer: The creator’s views expressed on this article don’t essentially mirror the views of Marine-Salvage. Data and charts, if used within the article, have been sourced from out there info and haven’t been authenticated by any statutory authority. The creator and Marine-Salvage don’t declare it to be correct nor settle for any accountability for a similar. The views represent solely the opinions and don’t represent any pointers or suggestions on any plan of action to be adopted by the reader.

The article or photos can’t be reproduced, copied, shared or utilized in any kind with out the permission of the creator and Marine-Salvage.

Do you will have data to share with us ? Suggest a correction

Latest Maritime Knowledge Articles You Would Like:

11 Interesting Facts About Great Australian Bight

7 Amazing Makassar Strait Facts

20 Largest Container Shipping Companies In The World In 2024

10 Amazing Beaufort Sea Facts

4 Major Ports in Micronesia

12 Interesting Facts About the PNS Ghazi Submarine

5 Biggest FPSOs within the World

11 Interesting Facts About Great Australian Bight

7 Amazing Makassar Strait Facts

20 Largest Container Shipping Companies In The World In 2024

10 Amazing Beaufort Sea Facts

4 Major Ports in Micronesia

Subscribe To Our Newsletters

By subscribing, you comply with our Privacy Policy and should obtain occasional deal communications; you may unsubscribe anytime.

Web Stories

About Author

Zahra is an alumna of Miranda House, University of Delhi. She is an avid author, possessing immaculate analysis and modifying abilities. Author of a number of educational papers, she has additionally labored as a contract author, producing many technical, inventive and advertising items. A real aesthete at coronary heart, she loves books just a little greater than anything.