Oil is a vital product that makes certain sectors feature, cars run, as well as power for human requirements is created. Oil books are just discovered in particular nations that export petroleum as well as various other petrochemical items around the world.

The liked ways of oil transportation is by sea, adhered to by rail.

Once an oil service provider gets to a port, where does it release its freight?

How is the place for storage space websites identified?

What are the preventative measures in position to stop mishaps?

Who are the significant international gamers in saving as well as dealing with oil?

Let’s have a look at the response to all these inquiries

In this short article, we will certainly take a comprehensive check out these frameworks that play a crucial duty in the international oil supply chain.

From building and construction as well as establishing, to the countless centers existing on website, this is your best short article on anything pertaining to oil terminals.

What are Oil Terminals Used for?

Briefly placed, oil terminals are storage space depots for oil, various other gas, as well as petrochemical items.

They are most typically discovered at ports as well as various other harbour centers to take care of inbound oil items. These can be either from inland oil resources that move gas through pipes, or from ships as well as oil vessels that berth at a port.

For the previous, these pipes offer an affordable technique of generating oil for export to the ports. From there, they are combined as well as on a regular basis utilized to renew outgoing vessels (LNG, oil, OBO providers). They likewise provide the gas that is utilized to run these ships.

Most ports nowadays supply refuelling capabilities within affordable prices. In the situation of oil-rich countries such as those in the Middle East as well as Western Asia, a section of the inland products is maintained apart for this. As providers are billed for the gas, the nation recuperates these prices.

In the situation of incoming ships as well as providers, the oil is utilized to meet the requirements of the nation. Such countries have little to no oil books as well as rely on oil-rich countries for power generation as well as crucial procedures.

At such ports, the oil is pumped in from ships as well as divided right into 2 groups of storage space silos.

A tiny section is utilized to refuel vessels at the port, while the remainder is lugged inland to oil depots for more department through pipes.

The use oil terminals is not limited to ports as well as various other maritime harbours. Any sector that includes making use of oil or gas from a kept depot likewise uses an oil terminal.

The specific terms might differ in these circumstances. However, they describe the very same layout concepts as well as security requirements.

As a basic guideline:

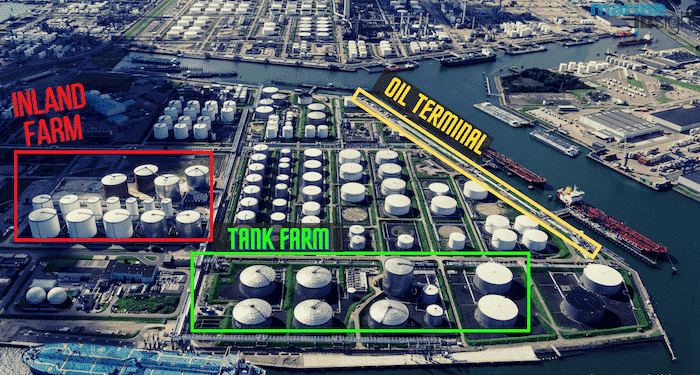

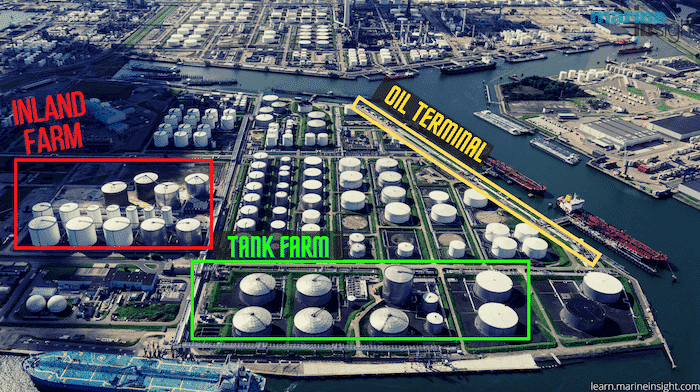

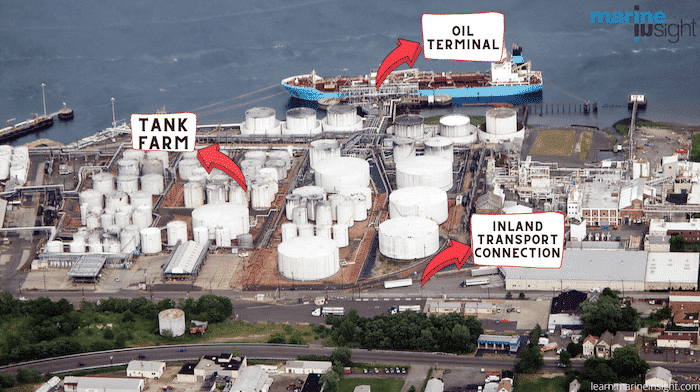

1. Oil Terminal— Portside or harbour center

2. Tank Farm— Multiple silos or containerized systems saving oil inland (term “farm” showing a number of systems at a combined place)

3. Oil Depot— Inland storage space website for oil

For circumstances, the air transportation sector utilizes gas as well as oil kept in oil depots within the flight terminal facilities. Such systems are referred to as air-fuel depots where roadway vessels fill up airplane gas products.

Petrol as well as diesel bunks utilized to fill out autos as well as various other roadway transportation cars likewise make use of oil depots (below ground terminals) for storage space functions.

Owning as well as Setting up Oil Terminals

Owning as well as establishing an oil terminal is really pricey as well as technological.

Due to the a number of variables that enter into play when constructing an incurable, just experienced specialists can undertake this.

The courses of possession that relate to traditional oil terminals are as complies with:

1. Single Owner— For big international gamers, having as well as running their very own depots is an extra viable choice. Companies such as Shell as well as Exxon supply oil to their numerous centers from these terminals.

2. Consortium— A consortium is a team of firms that interact for sure advantages. This consists of modern technology as well as understanding exchange, know-how, shared functional prices and so on It is the recommended setting of possession for smaller sized oil firms that can not venture right into creating a center on their own.

3. Independent Facility— In some situations, a personal third celebration might begin their very own oil storage space incurable as well as supply procedures. They hold oil books for a number of firms at once as well as bill them for the storage space as well as functional prices. One such firm is the Royal Vopak, based out the Netherlands.

4. Military Owned— These make use of different oil products as well as terminals from business usages for protection factors. The centers as well as procedures coincide as various other terminals, nonetheless, the competitor airplane or battleship gas will certainly be tailored for the engine as well as specs of the craft.

Setting up a terminal:

Setting up an incurable includes the adhering to actions:

1. Feasibility research study to identify the requirement for establishing

2. Location research study

3. Design quick as well as thorough evaluation

4. Manufacturing as well as building and construction of the incurable

5. Testing as well as security requirements

The expediency research study is carried out by specialists from developed oil firms. They are typically gotten to identify what design of possession the company should go with, the various other firms to companion with, as well as whether creating an oil depot is needed to begin with.

The place research study plays a significant duty in the future of the firm. It determines the maximum area in which the functional prices are lessened while likewise offered a big maintenance location.

Proximity to various other centers is likewise an essential aspect. An adequate range from cities is compulsory, such that the worst-case blast distance drops within the allowable area.

The layout quick as well as paper overview just how specifically the task will certainly be carried out. This consists of information of the workforce as well as tools needed, place researches, the software application to be utilized, methods to be adhered to throughout layout, as well as finally the detailed building and construction procedure.

Post- building and construction, screening needs to be accomplished to make sure that the oil terminal is running at optimal performance as well as security.

Considering the big quantity of oil kept within, there is a really high possibility that an unintentional stimulate might trigger a massive surge.

The screening procedure is an in-depth action which can take anywhere from a couple of days to a number of months to finish.

Facilities as well as Operations at Oil Terminals

Since the primary purpose of oil terminals is the risk-free storage space as well as handling of oil products, the centers existing on website are focused on this.

Minimum centers are guided in the direction of the handling or manufacturing of oil as well as various other petrochemicals. Sites as well as terminals at which some kind of manufacturing is carried out are referred to as “enhanced or advanced oil terminals”.

In basic, oil terminals can save 2 kinds of oil depending upon the oil-producing or getting nature of the nation. In the situation of countries that have oil books as well as export to various other areas, the terminals existing at ports are constructed to save petroleum as well as unrefined oil items.

This is due to the fact that they export petroleum for later refining. However, particular profession contracts need the refining of oil from the generating country itself, if the receiver does not have enough centers as well as modern technology to appropriately as well as securely fine-tune the imported petroleum.

For circumstances, China exports pre-processed oil with the hundreds of refineries it runs. On the various other hand, Russia usually exports petroleum that is later on refined right into bi-products.

In the situation of countries that are getting oil, the petroleum is sent out to a refinery initially and after that kept within the oil terminal. The just refining that occurs within the incurable silos is the enhancement of particular chemicals to support as well as convey preferable residential properties to the oil. The bulk of the procedures is automated to minimize the possibility of human mistake.

The oil terminal is positioned in closeness to the docks or jetties where oil vessels or various other service provider vessels berth.

Since most oil providers have hatch covers as well as small freight for dumping, cranes are offered along the size of the dock. There is tools to pump the petroleum from the holds, while there are likewise vapour recuperation centers at some ports.

The recuperation tools carries out a vital feature for the oil sector. Due to the minor balanced out in between the base of each hold as well as the nozzle where oil is drained, a substantial quantity of oil is squandered when we think about the countless lots of petrochemicals carried every year.

To accumulate the continuing to be section of oil that can not be accessed by the pump, the hold stress is quickly lowered up until the oil starts to evaporate. Thereafter, pumps are utilized to vacuum out the vapour, as well as they are after that compressed at assigned centers.

Considering the dimension of oil vessels, they are typically deep-water vessels that have a substantial draft. They can not dock at many ports as a result of the restrictions on inbound vessel dimension.

So, overseas websites are picked where the vessel can securely release its freight. Undersea pipes after that move the oil to the port where it is kept within the incurable silos.

Location plays a really crucial duty in the establishing of terminals. They should be within close closeness to a refinery (decreases transport prices) yet need to likewise allow the vessel to securely dock.

Lastly, the incurable should be attached to traditional ways of transport (roadway, rail, seaside, as well as inland) to make sure that oil from the terminals can conveniently be rerouted to inland depots.

The incurable silos have particular security functions to stop gas accumulation, unintended triggering, overpressure, as well as leakages. Another stipulation while constructing incurable silos is the decrease in vapour losses.

Over time, this can equate to a substantial loss in oil. A set roofing storage tank is a totally shut tank where a conelike or hemispherical dome is bonded to the cyndrical tube that develops the base of the silo. It can be utilized to save both fluids as well as vapours.

A shutoff referred to as a “breather valve” is utilized to soothe stress accumulation within the storage tank. Only reduced volatility items are kept within dealt with roofing containers, because high volatility materials might rapidly air vent with the rest shutoff as well as minimize the oil material.

Another idea typically utilized is the drifting roofing storage tank that can be either inner or outside. While inner roofings are unusual, the outside roofing is rather typical. Unlike dealt with roofing containers, the roofing of these containers is drifting.

It rests over the fluid, with minimal room for vapour accumulation. As the degree of oil increases or decreases, the roofing likewise relocates to stop any type of space for vapour development.

However, at really reduced oil degrees, the roofing gets to the storage tank base, where it acts as a repaired roofing storage tank. To stop vapour loss from the edge in between the roofing as well as covering, an edge seal is put. There are overviews that run vertically down the storage tank to make sure that the roofing stays straight in all times.

During the transfer to pipes or vessels, the oil is heated to enhance circulation features. For this, home heating coils are put at normal periods along the storage tank side.

Lastly, frameworks referred to as “Horton Spheres” are utilized for saving aeriform items such as LNG, butane, as well as lp.

These frameworks are utilized to stop tension damages as well as tiredness brought on by assistance development throughout the warming of pressed gases. It was designed by the Chicago Bridge & & Iron Company (CBI) that possesses a license for their layout as well as remains to construct Horton balls for business usage.

International as well as Domestic Laws as well as Safety Standards

Oil terminals are a hotbed for unintended surges as big products of unpredictable petrochemicals as well as various other items are kept.

Even a tiny stimulate near the storage space depots can trigger a collection of surges that might have alarming effects. To stop such events, there are countless global as well as residential legislations that position limitations as well as examine oil terminals.

There are likewise requirements utilized by inter-governmental bodies to make sure that the best products as well as enough security tools are utilized while on website.

The most typically followed global requirements are as complies with:

1. Safety Guidelines as well as Good Industry Practices for Oil Terminals, United Nations Economic Commission forEurope

2. Environmental, Health, as well as Safety Guidelines for Crude Oil as well as Petroleum Product Terminals,World Bank Group

3. Design, Construction, Operation, Maintenance, as well as Inspection of Terminal as well as Tank Facilities,American Petroleum Institute

4. Guidance for Oil Terminal Operators, International Maritime Organization, ISPSCode

5. Tank Farm Guidelines for the Chemical Industry,Basle Chemical Industry

6. Design Code for Aboveground Atmospheric Storage Tanks, API

7. Overfill Protection for Storage Tanks in Petroleum Facilities, API RP 2350

8. Prevention of Tank Bottom Leakage– A Guide for The Design as well as Repair of Foundations as well as Bottoms of Vertical, Cylindrical, Steel Storage Tanks, Engineering Equipment as well as Materials Users’Association

9. Tank Inspection, Repair, Alteration, as well as Reconstruction, API 653

10. Functional security– Safety instrumented systems for the procedure market market, International Society ofAutomation

11. Process Safety Management of Highly Hazardous Chemicals criterion, Occupational Safety as well asHealth Administration

12. Safety Guidelines as well as Good Practices for Pipelines, United Nations Economic Commission forEurope

13. OECD Guidance Concerning Chemical Safety in Port Areas, Organization for Economic Co- procedure as well as Development

Top 10 Oil Terminals Around the Globe

Oil terminals are typically possessed by a couple of big corporations that run a bulk share of these centers. The biggest gamers today are focused in China while the United States as well as Europe comply with behind.

The main metrics to determine the dimension of a firm selling oil terminals is with-

1. Number of oil incurable centers functional

2. Volume of oil dealt with per year

The leading 10 oil incurable handling firms are: (politeness Insights Global)

SNo Company No. of Terminals Oil Capacity (Million CBM)

| S No. | Company | No of Terminals | Oil Capacity (Million CBM) |

| 1 | Sinopec | 51 | 44.1 |

| 2 | Vopak | 69 | 33.1 |

| 3 | CNPC | 24 | 25.7 |

| 4 | Kinder Morgan | 96 | 21.7 |

| 5 | PetroChina | 34 | 19.8 |

| 6 | Buckeye | 114 | 18.1 |

| 7 | Oiltanking | 73 | 17.6 |

| 8 | Marathon | 99 | 16.7 |

| 9 | Enterprise | 55 | 13.2 |

| 10 | Magellan | 93 | 13.1 |

The firms are placed by order of the complete oil capability in million cubic meters per year. The leading 10 is led by Sinopec which has a lead of greater than 10 million CBMs over its local rival, Vopak.

On the various other hand, when we evaluate the variety of terminals each firm runs, Buckeye attracts attention as a clear leader with Marathon as the local rival.

Most firms are focused in China, as can be seen by Sinopec, CNPC, as well as PetroChina (done in the leading 5) with 89.6 million CBMs in between them. Vopak as well as Oiltanking are the primary European gamers with 50.7 million CBMs. Kinder Morgan, Marathon, Buckeye, Enterprise, as well as Magellan are from the United States with 82.8 million CBMs capability.

Sinopec is the international leader as well as is majorly possessed by the federal government of the People’s Republic of China (PRC). It runs over 30,000 fuel terminals as well as greater than 50% of the Chinese refineries.

With head office in Beijing, it has actually represented over EUR 300 billion in the previous fiscal year.

In Europe, Vopak is placed first as well as is based out of theNetherlands Operational because the previous 500 years, it is the biggest independent oil incurable firm. It has procedures in Europe, China, as well as the United States with a yearly turn over of EUR 1.25 billion in 2018.

The leading 10 firms comprise over 220 million CBMs of oil every year as well as shop 21% of the globe’s oil books.

Incidents as well as Accidents Involving Oil Terminals

As highlighted over, oil terminals as well as depots are possible websites of surges that can have an effect on the surrounding area also.

To stop this, it is very important to determine feasible resources of mishaps and after that develop reliable treatments to stop events.

In this area, we will certainly check out a combined listing of main reasons for oil incurable mishaps as well as the avoidance approaches.

Causes of Accidents

The main root causes of mishaps can be organized right into the adhering to groups:

1. Operational Error

a. Drain shutoffs mistakenly exposed

b.Overfill

c. SOP not adhered to

d. Vent closure throughout loading

e. Tank autos relocated throughout loading

f. High inlet temperature level

g. Oil leakages

2. Equipment or Instrument Failure

a. Thermostat failing

b. Oxygen analyzer failing

c. Floating roofing breakdown

d. Relief shutoffs unintended opening

e. Heater failing

f. Discharge shutoff tear

g. Overheating or supercooling

h. Vent shutoff failing to open up

3.Lightning

a. Poor grounding

b. Rim seal leakages

c. Direct hit

4.Static Electricity

a. Rubber seal cutting

b. Poor grounding

c. Fluid as well as strong transfer

5. Maintenance Error

a.Sparks

b. Non- surge proofing

c. Circuit shorting

d. Faulty welding

6. Tank Rupture

a. Poor soldering

b. Shell distortion

c. Poor manufacture

d.Corrosion

e. High- stress liquid back-up

f. Microbe caused product tiredness

7. Piping Leak

a. Low temperature levels

b. Leak throughout oil burglary from pipe

c. Flammable fluid leakage

d. Broken lp line

e. Pump leakage

8. Miscellaneous creates

a. Auto ignition

b. Runaway response

c. Natural tragedies

d. Open fire

e. Theft or arson

f. Terrorist strike (even more typical than various other assorted reasons)

Accident Prevention Methods

The numerous kinds of mishap avoidance approaches utilized at oil terminals are as complies with:

1. Design

a. Following requirements as well as laws

b. Hazard recognition

c. Safe range from habitation websites

d. Site assessment

2. Maintenance

a. Hot job authorization

b. Risk- based assessment

c. Use correct tools

d. Personal security tools

e. Environment tracking

f. Routine evaluations

g. Ventilation

3. Equipment

a. Pressure keeping

b. Corrosion resistance

c. Pressure alleviation systems

d. Vibration control

e. Grounding

4. Workplace

a. Static power security

b. Monitoring as well as dimensions

c. Hazard interaction

d. Waste oil as well as water therapy

5. Operation as well as monitoring

a. Following suitable SOP

b. Auto evaluations

c. Training as well as education and learning among workers

d. Safety audit

e. Ignition resource control

f. Safety laws

6. Miscellaneous checks

a.Grounding

b. Fire security

c. Risk evaluation

d. Emergency reaction

Source as well as referral:

Chang, James & & Lin, Cheng-Chung (2006 ).

A research study of tank mishaps [Internet].

Journal of Loss Prevention in theProcess Industries 19. 51-59. 10.1016/ j.jlp.2005.05.015.

You might likewise such as to check out:

- What Are Different Types of Ports For Ships?

- 11 Major Container Terminal Operators In The World

- Top 10 Biggest Ports in the World in 2021

- Top 10 Busiest Ports In The World

- Major Container Ports And Port Operators in the World In 2020

Disclaimer: The writers’ sights revealed in this short article do not always show the sights of Marine-Salvage Data as well as graphes, if utilized, in the short article have actually been sourced from readily available info as well as have actually not been confirmed by any type of legal authority. The writer as well as Marine-Salvage do not assert it to be exact neither approve any type of obligation for the very same. The sights comprise just the point of views as well as do not comprise any type of standards or suggestion on any type of strategy to be adhered to by the viewers.

The short article or photos can not be recreated, duplicated, shared or utilized in any type of kind without the approval of the writer as well as Marine-Salvage