Imagine a full-sized ship or a plane constructed of automated systems with appropriate accuracy, like a published entity, and also having very little human initiative! Sounds insane, best?

But this might be an opportunity in the not-so-far future! And all credit history mosts likely to the revolutionary sensations of 3-dimensional printing or 3-D printing. This modern technology has actually developed rather a large mix throughout numerous sectors over the last couple of years, with automation getting remarkable appeal.

An innovation which can produce life-sized items with precision, practically comparable to a computer system printer publishing a sheet of paper! Well, below we have many various other advantages of computational innovations and also automation.

Johannes Gutenberg presented the printing machine modern technology as very early as 1440, and also ever since, printing has actually advanced drastically. 3D printing, or creating real-life three-dimensional items, was developed in the 1940s and also 1950s.

However, it was not prior to 1984 that Chuck Hull of 3D systemsCorp developed background by effectively creating a totally functioning 3D printer and also getting a license for globally industrial use. Now, allow us go deeper right into the issue.

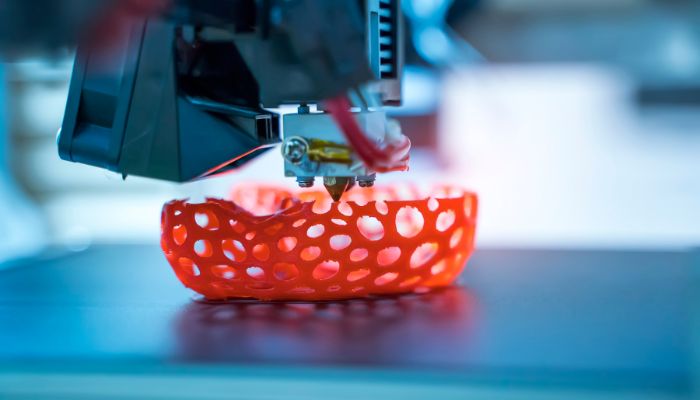

The Process Of 3D Printing

3D printing, as the name recommends, is the procedure which can produce life-sized genuine items from predetermined versions making use of automatic production innovations. After offering all required inputs pertaining to CAD documents and also preferred version depictions to the device, there is very little human treatment called for. The whole procedure is thought about similar to the modern technology of printing.

How does a 3D printer instantly function?

It is not such as a whole sculpture, or a set of footwear will certainly bulge of a gadget like a copy machine, printer, or perhaps a snacks device that you are made use of to seeing in motion picture theaters! It is totally impractical! Neither does it work with the timeless strategy of ‘carving’ from a solitary block of liquified plastic, timber, or steel and also progressively developing the form, likewise referred to as “subtractive manufacturing.”

Much like its name, a 3D printer generally deals with the concept of traditional inkjet printing itself. It develops or increases a framework or a things by including products, treating them, and also happening the best appearance or arrangement layer after layer for all useful objectives. Hence, it can likewise be viewed as an approach of “additive manufacturing.”

A 3D printer includes a system of linked systems, which might really feel comparable to that seen in manufacturing production line or producing systems, however a lot smaller sized.

The arrangement and also intricacy of a 3D printer might differ based upon demand- often, it might be as tiny as a red wine fridge or as huge as a collection of supercomputers; often, it might have simply a solitary robotic arm or a collection of several arms and also various other challenging systems.

The job is likewise not that tough to comprehend. A 3D printer develops out a things layer by layer, as discussed over, by integrating the correct amounts of basic materials positioned, obviously.

The basic materials are generally expelled via nozzle-like electrical outlets of numerous kinds looking like adhesive weapons in guaranteed predetermined quantities and also circulation prices. The whole trajectory of procedure of the mechanical arms is under computer system control.

The concept can likewise be finest envisioned by just thinking of a loaf of bread reduced right into pieces. Here, it is totally turned around. A 3D printer deals with molding all called for pieces layer after layer by continuously publishing and also persuading the exact same location till conclusion and after that developing the entire item in a bottom-up feeling. Or instead, in straightforward terms, adhesive back specific pieces of bread to produce a bigger loaf.

This bottom-up feeling of positioning is likewise referred to as extrusion in technological terms. The main point behind 3D printing can likewise be originated from below ground rock developments layer by layer for many years.

Now, making every layer is made complex, unlike an easy loaf of bread. This concept of layer-by-layer development of a 3D item is practically referred to as stereolithography; something owed to Hull also.

Step- by-Step procedure of 3D printing

Modelling

This is the most importantly action, like any kind of various other automatic or computational modern technology. A schematic depiction or plan of the preferred item is produced making use of CAD bundles. This might be at first stood for as a 2D documents and also later on changed right into 3D.

The version is examined very carefully, and also any kind of mistakes or disparities are corrected. These versions are frequently conserved electronically as Stereolithography File Format or STL Modern innovations likewise make use of upgraded styles like Additive Manufacturing File Format or AMF

Pre- handling and also Preparation of the printer

After developing the 3D plan or version, the documents is moved to the device input end for unification. The device checks out the documents and also shops it in its system drives online. Then the printer system is prepared. All called for basic materials are loaded, like plastic, steels, binders, materials, and so on

All 3D printers have actually pre-installed premium software program for checking out the documents. The printer’s pre-programmed software program more checks any kind of problems in the STL documents, like problems, geometric flaws, suspensions, voids, openings, breaks, breaks, self-interactions, or any kind of various other abnormalities.

After authorization of the last version in STL, the software program after that streamlines the version right into straightforward layers or specific“slices” This is basically comparable to the procedure of meshing in architectural evaluation software program. The printing user interface likewise establishes the series of procedure. After all this, the last collection of guidelines is produced as a G-code documents which prevails for all Computer-Aided Manufacturing systems.

The proficiency of the software program is extremely crucial as the whole work occurs based upon the code documents sent out. Any min mistake can make the version fall short and also look like a severely compressed birthday celebration cake!

Final Preparation of the Object

There is very little to do at our end after the above. The device is ultimately advised to continue by striking the “Print” switch on our computer systems. Then the printer complies with the exact same series of procedures and also trajectory of procedures to produce the last product.

Everything like the choice of the raw products, ejection of the exact quantity of products at the correct time with the circulation, the trajectory of the arms over the item, periods in between 2 succeeding layers, and so forth is completely scripted or based on the formula established by the printer based upon the plan and also STL documents.

The room in between them is integrated for each 2 succeeding layers making use of adhesives, binders, or in-situ warm therapy innovations like laser beam of lights or UV radiations. Usually, the drying out time is brief, and also the printing arms carry on to the following succeeding layer or cross-section after a brief duration once the coming before layer strengthens.

Different Techniques in 3D printing and also sort of printers

While the main controling concept stays the exact same, the methods for publishing 3D items can be of numerous kinds. The most typical and also commonly made use of one is Fused Deposition Modeling/ FDM

This includes erupting fluid product at regulated prices over the exact same location over and also over once more till and also unless it solidifies to develop succeeding layers over each other. This concept completely makes use of the timeless concept of extrusion and also is made use of by a lot of 3D printing jobs. Extrusion nozzle heads regulate the home heating and also readjust the circulation prices.

The nozzle heads are powered by electric motors which regulate their motions, the product circulation prices, and also the temperature levels. As discussed over, the CAD documents certain to FDM is refined by the system to produce camera documents information which is after that taken as the resource. However, FDM does not put on some complicated geometries and also certain products.

Granular product binding is one more comparable technique to FDM, where products precisely impinge right into the granular bed. After the layer is bound, it is lowered, and also the procedure is duplicated for various other layers till the item is accumulated.

Direct Material Laser Sintering, Selective Laser Melting, and also Electron Beam Melting are various other innovative methods that make use of exterior home heating resources to generate more challenging items, specifically ideal for steels and also complicated geometries.

Some 3D printers are worldly jetting, binder jetting, powder bed blend, guided power deposition, sheet lamination, and also barrel polymerisation.

Future of 3D Printing and also Use in the Shipping Industry

3D printing has lots of benefits and also an encouraging future. They are much faster, precise, more secure, and also do not call for much human initiative. Though the procedure is pricey and also frequently has constraints, numerous markets, consisting of protection, production, aeronautics, and also also medical care, are turning to looking for higher applications of 3D printing. As per records, it is currently a 3-billion-dollar market every year and also is anticipated to climb better.

As much as the aquatic market is worried, 3D printing is currently being made use of to produce numerous products like prop components, appendages, and so on In the future, the market is expecting even more applications in the building and construction of ships and also submarines.

One of the benefits is that if this technique is made use of wisely, essential parts can be constructed without the demand of much assemblage. In in this manner, it can conserve time and also confirm to be economical. The 3D-printed blocks can after that be collaborated.

You may likewise such as to review

- Watch: Patrol Boat Printed From World’s Largest 3D Printer

- Video: Using 3D Printing To Make Spare Parts On Maersk Tankers

- Watch: United States Navy’s Largest 3D Printed Asset– ‘Submersible Hull’

- The 10 Best Printers For Shipping Labels

- 7 Technologies That Can Change The Future of Shipbuilding

Disclaimer: The writer’s sights revealed in this short article do not always show the sights of Marine-Salvage Data and also graphes, if made use of, in the short article have actually been sourced from offered info and also have actually not been verified by any kind of legal authority. The writer and also Marine-Salvage do not declare it to be precise neither approve any kind of obligation for the exact same. The sights make up just the point of views and also do not make up any kind of standards or referrals on any kind of strategy to be complied with by the viewers.

The short article or photos can not be recreated, duplicated, shared, or made use of in any kind of kind without the approval of the writer and also Marine-Salvage

About Author

Subhodeep is a Naval Architecture and also Ocean Engineering grad. Interested in the ins and outs of aquatic frameworks and also goal-based style elements, he is devoted to sharing and also breeding of typical technological understanding within this market, which, at this actual minute, needs a turnabout to grow back to its old splendor.