ABB as well as Ballard are proceeding with their industry-leading collaboration to decarbonize aquatic transportation as well as have actually obtained an AiP from DNV for their high-power gas cell idea, the growth of which was released in 2018. An AiP is a significant turning point in establishing brand-new modern technology as an independent analysis of the idea, verifying that the layout is possible as well as no considerable barriers exist to stop the idea from being recognized. With the AiP in position, the collectively created option can be finished within the following number of years for application onboard a vast array of vessels.

“We are pleased to have worked with ABB and Ballard on this AiP,” stated Tuva Flagstad-Andersen, Regional Manager North Europe, DNVMaritime “Hydrogen plays an important role in the energy transition, so it is essential to establish safe technologies that the industry has confidence in. As an early phase verification for new design concepts, based on long-standing, trusted and independent standards, an AiP can help build this confidence.”

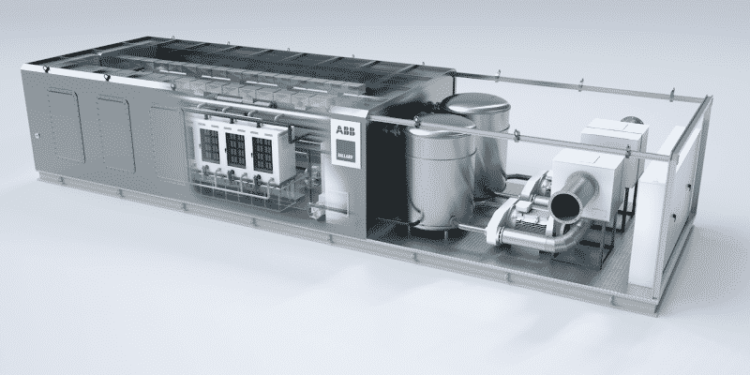

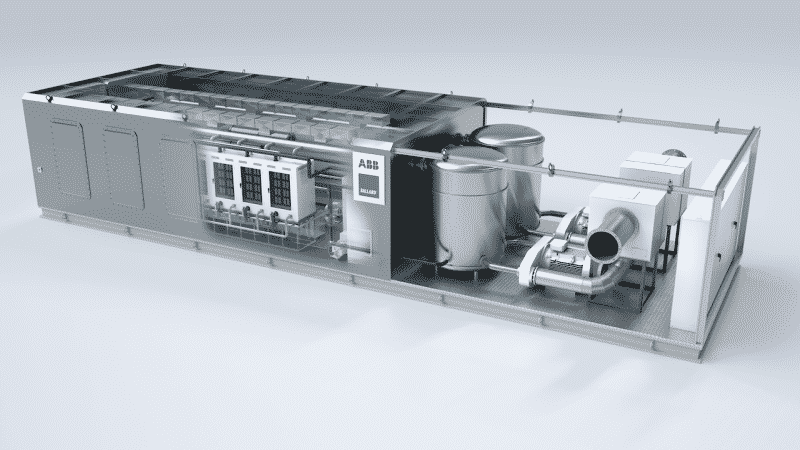

The high-power gas cell device is a versatile option that will certainly sustain the power requirements of a varied variety of vessels needing numerous 3 MW blocks of power. A cruise ship vessel operating in seaside locations can either run totally on gas cell power or button to it when running in eco delicate locations or discharge control areas, while a ferryboat with a routine routine as well as constant bunkering chances can run exclusively on gas cell power. For sea going vessels, gas cell power can sustain supporting requirements. The idea of the option likewise imagines the combination with a power storage space system.

“ABB’s industry-leading experience in marine solutions and Ballard’s expertise in development and deployment of megawatt-scale fuel cell systems for land-based use has proven to be the right combination, enabling us to take the next step in our joint efforts to make this technology available for larger vessels,” stated Jesper Themsen, President as well as CHIEF EXECUTIVE OFFICER of Ballard Power Systems Europe A/S. “Securing an AiP offers a signpost to the maritime industry regarding the potential of this truly transformative concept.”

“This AiP is an important milestone in making high-power fuel cells commercially available, and it underpins our commitment to bring new levels of efficiency, reliability and sustainability to the global shipping industry,” stated Juha Koskela, Division President, ABB Marine & &Ports “As we continue to pave the way toward decarbonizing shipping, we are confident that vessel electrification, including fuel cell technology, will play a pivotal role in helping the marine industry achieve its environmental targets.”

The effective growth of a high-power gas cell system idea improves a cooperation in between ABB as well as Ballard, the leading worldwide carrier of proton exchange membrane layer (PEM) gas cell services, started in June 2018. As component of its technique to establish alternate emission-free innovations, ABB is currently well progressed in collective growth of gas cell systems for ships. Considered amongst one of the most appealing innovations readily available in regards to greenhouse gas decrease, zero-emission hydrogen gas cells are currently powering smaller sized vessels over brief ranges as well as the modern technology gets on the brink of awaiting setup on bigger ships.

Shipping adds near to 3 percent to worldwide greenhouse gas discharges (GHG) yearly as well as stress to shift the market to even more lasting source of power has actually led to set decrease targets from the International Maritime Organization (IMO), a United Nations firm in charge of managing delivery. IMO intends to reduce for GHGs from ships by a minimum of half by 2050 from 2008 degrees.

Fuel cells transform the chemical power from hydrogen right into power with an electrochemical response. When renewables are made use of to create the hydrogen, the whole power chain can be tidy. Having a bigger, megawatt-scale power device makes it possible to incorporate systems to get to a lot greater complete power than is virtually feasible with smaller sized power systems.

Demand for hydrogen, which has actually expanded greater than threefold because 1975, remains to rise1. Scaling up innovations as well as reducing prices of manufacturing is essential to allow hydrogen to come to be commonly made use of. ABB is working together with consumers as well as companions to establish as well as incorporate modern technology that will certainly make hydrogen an obtainable, inexpensive element of the globe’s reduced carbon power mix.

In Italy, ABB is partnering with Swiss energy business Axpo to establish modular environment-friendly hydrogen plants that intend to develop a maximum operating version to create inexpensive, environment-friendly hydrogen. In France, ABB is providing its Freelance dispersed control system as well as ABB Ability ™ Manufacturing Operations Management electronic system to the very first manufacturing website for Lhyfe, a manufacturer as well as provider of one hundred percent environment-friendly hydrogen.

ABB is likewise collaborating with Hydrogen Optimized, a lasting power conversion business in Canada, to collectively discover the growth of massive environment-friendly hydrogen manufacturing systems attached to the electric grid to use a tidy, lasting, as well as inexpensive power provider.

Reference: abb.com