ABB’s Azipod Propulsion Marks 300th Vessel Milestone With Eco-Friendly Orange Marine Cable Ship Contract

Integrated ABB power and also propulsion bundle win from Colombo Dockyard brings turning point Azipod ® setup for sophisticated cable-laying and also repair work vessel that will certainly sustain overseas wind ranches.

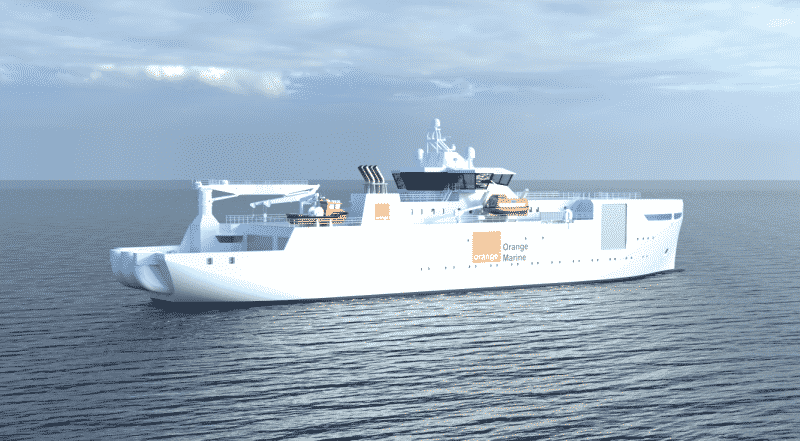

The sophisticated vessel will certainly be provided by Sri Lanka’s leading shipbuilder in 2023, signing up with an Orange Marine France fleet which currently makes up 15 percent of the globe’s specialized cord laying and also repair work ships. The 100-metre vessel will certainly include a complete power, propulsion and also automation bundle from ABB, consisting of the spots Azipod ® system. Financial information of the agreement were not divulged.

The vessel, required for both cord laying and also repair work, has actually been created by Norway’s Vard Design, a Fincantieri Company, to satisfy particular concerns on power usage and also efficiency. Station- maintaining precision and also ability to move are important of what can be complicated cord laying and also fix procedures, while the ship likewise requires reasonably broadband to attain fast or immediate implementation.

Image Credits: Orange Marine

“We look forward to working with ABB on this highly advanced, modern vessel that will no doubt set new standards for cableships in term of superior performance and eco-friendly operations,” statedMr D.V. Abeysinghe MD & & CHIEF EXECUTIVE OFFICER, Colombo Dockyard.

The twin 1.8 megawatt Azipod ® devices chosen to satisfy the shipowner’s needs for high transportation rates with optimum gas effectiveness while giving the 360-degree ability to move to make sure station-keeping efficiency also in difficult climate condition. Also essential to the bundle is an ABB power storage space system making it possible for electric power back-up utilizing 500 kWh batteries, which will certainly lower gas usage throughout cord job and also make sure connection in case of an unanticipated closure.

“Azipod® propulsion was an obvious choice,” stated Emmanuel Décugis, New Building Project Manager,Orange Marine “It combines optimal maneuverability with reduced power requirements and low emissions. At the same time, being able to integrate different energy sources provides a flexible and future-proof system that will ensure the most efficient vessel operation for many years to come.”

The general power configuration will certainly be regulated by ABB’s Power and also Energy Management System (PEMS ™), which will certainly likewise enhance mistake resistance and also give a high level of dependability while guaranteeing the optimum life time for the batteries.

The incorporated power and also propulsion agreement comes as ABB commemorates thirty years of Azipod ® propulsion and also provides the most recent instance of just how the idea’s resourcefulness remains to incorporate with modern improvements to increase its customer base, 3 years after launch.

“After 30 years of Azipod® propulsion, it is especially pleasing that the 300th ship will be a pioneer in the world’s energy and communications sector,” stated Juha Koskela, Division President, ABB Marine & &Ports “We are also delighted to be working on our second project with Colombo Dockyard, following an earlier cable layer project in 2017.”

Azipod ® modern technology provides proprietors recorded gas cost savings of 20 percent over traditional shaftline services, decreased exhausts and also complete assimilation with high effectiveness crossbreed power setups. As well as maximizing room onboard for various other usages, the Azipod ® system’s exterior place permits ship developers to enhance hull type efficiency. Connecting the prop straight to the propulsion electric motor removes equipments and also various other supporting tools, decreasing upkeep prices.

Vessel kinds for which sophisticated Azipod ® propulsion systems use substantial effectiveness gains currently consist of cord layers, overseas building vessels, wind ranch assistance ships, icebreakers and also ice-breaking industrial ships consisting of LNG (melted gas) service providers, and also cruise liner consisting of exploration vessels.

Once in procedure, the brand-new Orange Marine vessel will certainly fit 76 employees and also will certainly be from another location checked and also sustained by professionals from ABB’s worldwide network of ABB Ability ™Collaborative Operations Centers Remote assistance and also connection, along with sophisticated information analytics allowed by the ABB Ability ™ Remote Diagnostics System, will certainly boost functional security and also efficiency, while aiding to find and also fix mistakes immediately aboard.