Thordon Bearings stated ABS released an Approval in Principle to the “sterntube-less ship” principle established together with the Shanghai Merchant Ship Design & & Research Institute (SDARI), the National Technical University of Athens (NTUA) as well as Thordon Bearings Inc.

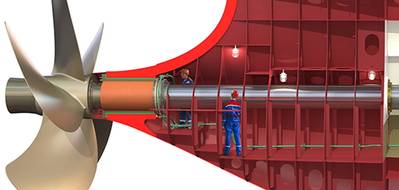

The style changes a vessel’s sterntube with an uneven designed chamber that permits a much shorter, water-lubricated prop shaft to be evaluated as well as preserved while the vessel is afloat, without needing to take out the shaft in drydock.

While the principle entirely gets rid of the demand for oil-lubricated sterntube seals as well as bearings.

Anthony Hamilton, Technical Director, Thordon Bearings, stated the principle changes the ships’ typical covered prop shaft. “We started wondering why a vessel with a water-lubricated shaftline needs a sterntube. Why couldn’t the shaft simply run in the larger space outside the sterntube? This space is designed into virtually all vessels where an oil-lubricated sterntube is traditionally exposed to seawater for cooling. With a water-lubricated shaft this space still exists but it’s wasted space.”

Hamilton stated the room might be utilized to access the shaft for examinations, as well as a great deal of the shaft setup as well as functional obstacles “completely disappear”.

A sterntube-less ship includes a much shorter shaft with the prime moving company additionally aft the vessel. An extra bulkhead seal as well as a torsional resonance damper would certainly be called for however there is no aft seal as well as Thordon’s COMPAC salt water lubed birthing changes the oil-lubricated bearing aft.

“ABS and the Technical University of Athens have done the math and the engineering behind it. They’ve looked at system pressures, temperatures, loads, noise and vibration levels, shaft alignment – everything works,” stated Hamilton.