ABS-Approved Sterntube-Less Ship Concept To Save Shipowners Thousands While Keeping Oceans Clean

Thordon Bearings has today invited the news by category culture abdominal muscle to honor Approval in Principle to the “sterntube-less ship” idea established together with the Shanghai Merchant Ship Design & & Research Institute (SDARI), the National Technical University of Athens (NTUA) as well as Thordon Bearings Inc.

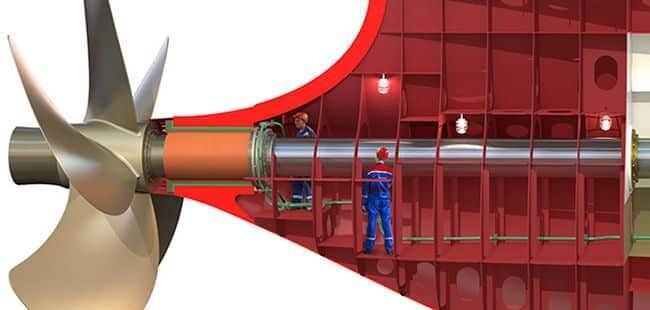

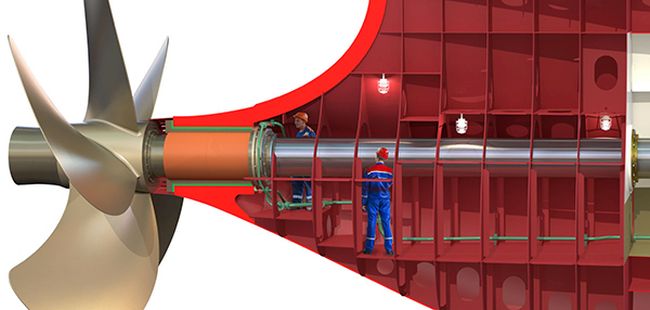

The advanced style changes a vessel’s sterntube with an uneven designed chamber that enables a much shorter, water-lubricated prop shaft to be examined as well as kept while the vessel is afloat, without needing to take out the shaft in drydock.

While the idea entirely removes the requirement for oil-lubricated sterntube seals as well as bearings– a significant resource of aquatic contamination– the style is most likely to conserve shipowners thousands of countless bucks in funding as well as functional expense over a vessel’s life expectancy.

Speaking in advance of an ABS-organized workshop in Athens throughout the Posidonia profession fair, Anthony Hamilton, Technical Director, Thordon Bearings, stated the idea “revolutionizes the ships’ traditional sealed propeller shaft”.

“We started wondering why a vessel with a water-lubricated shaftline needs a sterntube. Why couldn’t the shaft simply run in the larger space outside the sterntube? This space is designed into virtually all vessels where an oil-lubricated sterntube is traditionally exposed to seawater for cooling. With a water-lubricated shaft this space still exists but it’s wasted space.”

Hamilton stated the area can be utilized to access the shaft for assessments, as well as a great deal of the shaft installment as well as functional obstacles “completely disappear”.

A sterntube-less ship includes a much shorter shaft with the prime moving company additionally aft the vessel. An added bulkhead seal as well as a torsional resonance damper would certainly be called for yet there is no aft seal as well as Thordon’s COMPAC salt water oiled birthing changes the oil-lubricated bearing aft.

“ABS and the Technical University of Athens have done the math and the engineering behind it. They’ve looked at system pressures, temperatures, loads, noise and vibration levels, shaft alignment – everything works,” stated Hamilton.

Craig Carter, Thordon Bearings’ VP Business Development, stated:“There are huge savings here. You would never have to withdraw the shaft again, which can cost $100,000 plus in drydocking costs alone. We are not changing the design of the ship or the stern but by moving the engine further aft we free up more space for cargo.”

Dr Chris Leontopoulos, Director Global Ship Systems Center, ABDOMINAL MUSCLE Athens, stated: “The use of seawater to lubricate the propeller shaft is well-established but the proposed design takes this further by removing the sterntube, decreasing the shaft line length, reducing engine room space and increasing the cargo space. It enables significant efficiencies and cost savings for operators.”

Thordon Bearings is taking shipowners, shipbuilders, repairers as well as participants of the naval continue a digital trip of a sterntube-less ship on the Thordon (Technava) cubicle 3.111, throughout the Posidonia exhibition, which occurs today, in Athens, Greece.