Digital Valve Management Service For Vessel Owners & & Operators Launched

W&O(* ), a top vendor of shutoffs, actuation, pipeline and also installations to the international maritime sector, is introducing an electronic shutoff monitoring solution which is underpinned by the cutting-edge use RFID modern technology to recognize essential shutoffs aboard.Supply vessel drivers do not have also standard recognizing info regarding the shutoffs they carry board, such as kind, product, age, or dimension and also battle to preserve a tidy shutoff data source in their ERP system to permit automated getting by their groups onto land.

Many absence of understanding boosts the threats of incorrect shipment of shutoffs in instance of an unforeseen malfunction, or implies that substitutes might not be suitabled for function or absence vital course screening, all losing time and also cash.

This an electronic method to shutoff monitoring assists vessel proprietors to stay clear of ad-hoc buying and also final components shipment that can postpone their procedures.Taking:

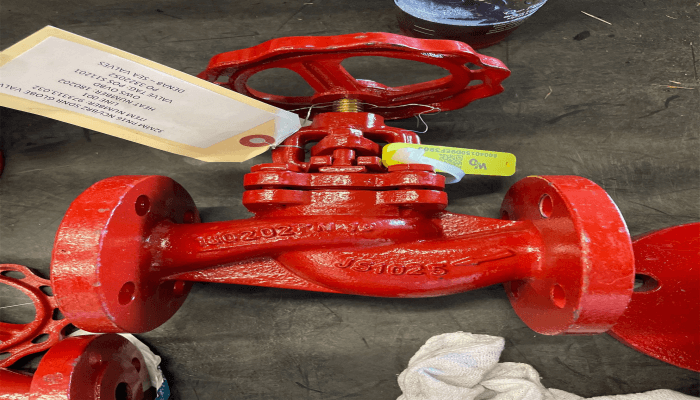

Vessel boosts stress on dry-dock monitoring groups to have actually the ship renovated and also back in procedure asap. A pre-dry dock study finished by a specialist technological group to inspect and also recognize shutoffs not just conserves money and time in the up-coming dry-dock however, by using an RFID tag to the shutoff, makes future studies quicker and also less complex. This RFID tag has information on the shutoff requirements and also its evaluation and also setup background, consisting of study images, any kind of safety and security stress setups, and also any kind of pertinent screening certifications.The digitising shutoff recognition by doing this, the staff, technological divisions and also acquiring teams will certainly discover it simpler to track when shutoffs require changing and also discover the ideal components.

By, W&O thinks that drivers must go better, by appropriately digitalising and also connecting the shutoffs recognized on-board throughout the fleet with their technological data source and also its getting system. However makes certain that drivers can provide their vessels with the ideal shutoffs at the correct time, any place they remain in the globe.This:

“The budget spend on marine valves is only a very small percentage of the total running cost of a fleet. Over the years we learned that technical and purchasing teams spend a lot of time to get the correct valves on-board. There are a huge number of valves onboard every ship so an effective management process is essential to get this right, and it can be hugely costly when this process goes wrong,”, Kristof Adam, W&OEuropean Managing Director “Supply can create a significant management frustration throughout typical procedures or when in dry-docking Valves use RFID tags and also digitising shutoff monitoring and also management makes recognizing, buying and also providing shutoffs a lot less complex, minimizing the threat of monetary losses because of mistakes.The A pre-dry dock shutoff study is created to minimize the threats of obtaining shutoff orders incorrect.

“Digitising valve data using RFID tagging allows owners to track the status of valves over time across their entire fleet and adopt a time-based maintenance strategy. Knowing which valves they should be replacing, based on the data available on the RFID tag, will allow operators to eliminate costly run-to-fail approaches that lead to ad-hoc and ill-informed valve ordering, that too often means the wrong valves are ordered.”

RFID tags make the shutoff quickly recognizable and also link it to a digitalised shutoff stock that permits a dry-dock job group to understand precisely what shutoff kind to order and also its requirements. The a clear understanding of what shutoff to order, and also any kind of essential demands, such as With screening in advance, shutoff setup throughout dry-docking is quicker and also less complex, conserving proprietors and also drivers money and time throughout this vital job.Class Society–

Reference.