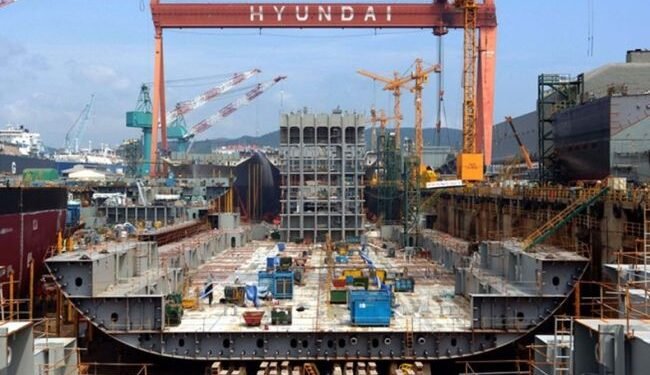

DNV GL has actually provided Hyundai Heavy Industries (HHI) with a basic authorization for ship application (GASA) for a brand-new idea of large unrefined service providers (VLCCs) with a centreline oil-tight longitudinal bulkhead. The brand-new layout will certainly decrease possible damages and also functional threat by including an easier architectural setup, filling patterns and also piping setups.

Vidar Dolonen, DNV GL Regional Manager for Korea & &Japan, supplied the certification to Seung Ho Jeon, Executive Vice President of HHI at the shipyard team head office inSeoul Vidar Dolonen, DNV GL Regional Manager for Korea & & Japan, provided the certification to Seung Ho Jeon, Executive Vice President of HHI, in Seoul.

The brand-new VLCC with a centreline longitudinal bulkhead layout idea was established by HHI, noting a globe initially. The idea presents a solitary centreline layout with 2 rows of freight storage tanks, leading to 7 sets of storage tanks and also one added set of slop storage tanks.

Image Credits: dnvgl.com

The major advantage is a renovation in the driver’s comfort in regards to cleansing, evaluation and also upkeep by easier architectural, filling and also piping setups, along with the decrease of piping systems and also tools because of a smaller sized variety of freight storage tanks. Furthermore, the gas intake was boosted by establishing brand-new layout lines for the brand-new VLCC with a centreline longitudinal bulkhead.

“Through joint development projects with DNV GL, we aim to develop new technologies which enable our clients to comply with environmental regulations and navigate their vessels in a safe and efficient way,” claimedSeung Ho Jeon “We believe the recent GASA approval is opening up a new era of VLCC designs which significantly strengthen the competitiveness of these HHI built ships.”

“The purpose of DNV GL is to contribute to the construction and operation of smart and safe ships. We are pleased to have collaborated with HHI in this exciting project and we wish the shipyard further success with its new VLCC design,” claimed Vidar Dolonen.

As component of the GASA range, DNV GL executed a complete architectural confirmation and also usefulness research study according to category policies and also integrated typical architectural policies (CSR). The information were verified by a great mesh evaluation and also a tiredness evaluation. In enhancement, the sloshing and also regional resonance evaluations for freight storage tanks were assessed in a relative research study to improve the architectural integrity of this brand-new VLCC.

Reference: dnvgl.com