New DNV GL research study based upon greater than 1,000 failing instances has actually disclosed that tubes and also piping are one of the most failure-prone elements in the oil and also gas and also maritime markets. Fatigue and also deterioration are one of the most usual failing kinds.

The research study is based upon instances from DNV GL’s international network of 5 labs in the United States, Europe and also Asia, which are experts in failing examination.

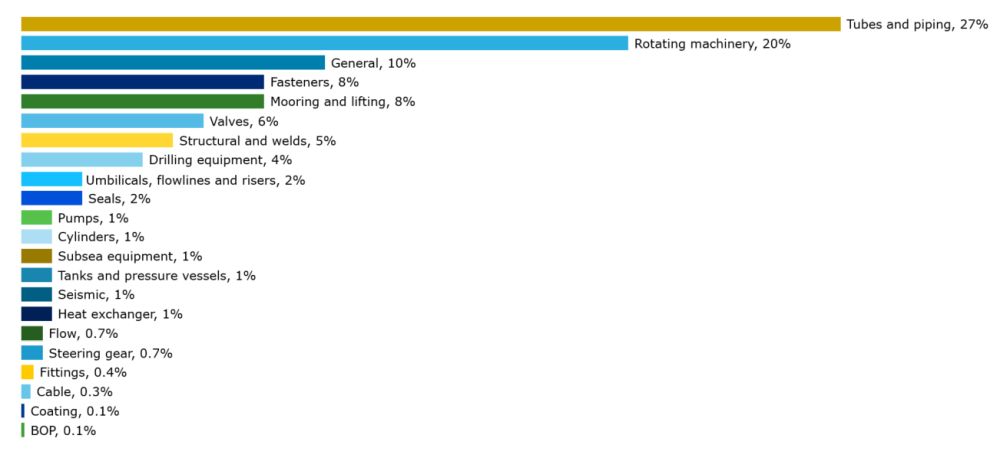

The labs recognized that, of the elements they analyzed, greater than a quarter (27%) of failings happen in tubes and also piping, and also a 5th (20%) in revolving equipment. Fasteners, and also mooring and also training elements likewise show up in the leading 5 elements most vulnerable to failing.

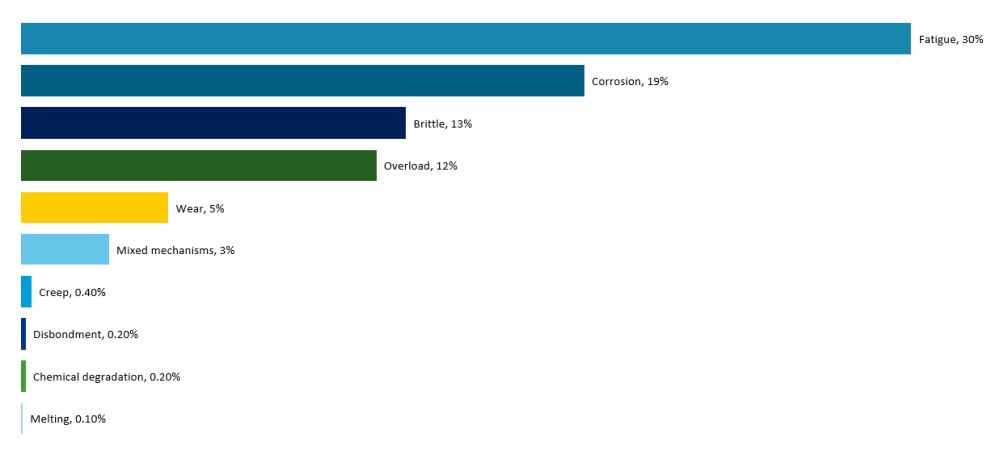

Fatigue (30%) and also deterioration (19%) compose virtually fifty percent of the main failing kinds happening in the events DNV GL evaluated. Brittle crack, overload and also wear are likewise in the leading 5.

“The cost of prevention, monitoring, repair or replacement as a result of these forms of component degradation can run into billions of dollars. Potentially, financial penalties can occur if major incidents and loss of life result from such a failure. Our experts can provide in-depth technical advice to prevent future failure on similar components that keep operations running and importantly keep the workforce safe,” stated Koheila Molazemi, Technology and also Innovation Director, DNV GL– Oil & & Gas.

To get the information for its research study, DNV GL’s lab professionals used a number of approaches to evaluate information and also documents to evaluate failing fads and also anticipate what elements are probably to fall short. This consisted of ingenious methods using sophisticated internet search engine innovations incorporated with technological topic competence. DNV GL remains to boost this method with its clients.

This organized logical method implies high quantities of information can be analyzed even more quickly than making use of conventional data sources and also spread sheets.

The buildup of even more and also much better information and also understandings from failings can be used in the front-end engineering style stage of growth tasks to craft even more durable properties. During procedures, understandings can boost optimization of examination, fixing and also upkeep for extra effective and also more secure use funding and also individuals.

Reference: dnvgl.com