DNV Verifies Survitec’s New Ultrasound Method For Fire Fighting Foam Tests

Classification culture DNV has actually provided a confirmation declaration permitting international survival modern technology expert Survitec to utilize its game-changing fire foam screening procedure onboard maritime vessels or overseas frameworks.

Survitec’s brand-new Produced Foam Live Test technique makes use of ultrasound modern technology to confirm the efficiency of fire-fighting foam, according to the obligatory needs laid out in IMO MSC.1/Circ1432 9.2.4.

The judgment relates to any type of vessel or overseas framework that has a deck foam system, a high development foam system (engine area) or Heli- deck foam system. Foam proportioner or various other blending tools require to be evaluated every 5 years to verify that the blending proportion is within +30 to -10% of the small blending proportion specified by the supplier.

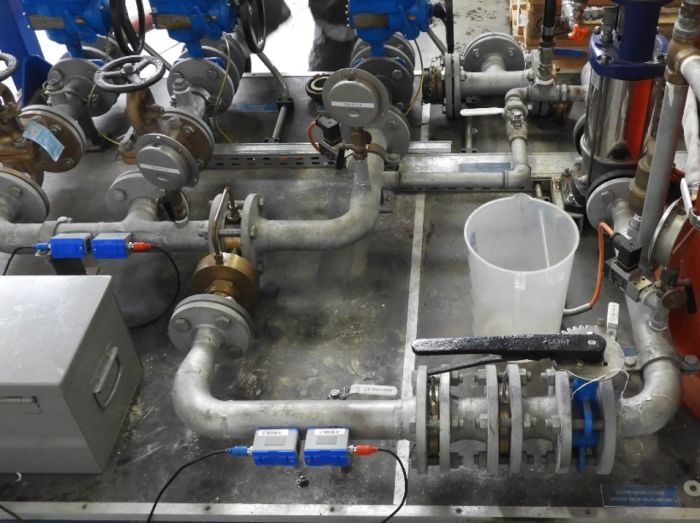

Image Credits: Survitec

However, while ultrasonic circulation meters are typically to gauge liquid circulation in pipework, it is believed to be the very first time ultrasound modern technology has actually been made use of to evaluate the precise water/foam proportion. Two ultrasonic circulation meters are made use of to contrast both worths.

Jan-Oskar Lid, Technical Sales Manager, Survitec, stated: “We have developed a safe, environmentally sound and predictable test method removing a lot of the time and expense involved in foam sampling and testing. It delivers peace of mind to ship operators and crews.”

Unlike existing methods, the Survitec technique implies screening can be carried out while the vessel is berthed along with, without needing to release any type of foam too far or send out examples to screening laboratories.

Current examination methods need to run the fire-fighting system with foam for at the very least 2 mins, so there is a hefty intake of pricey concentrate, typically causing the demand to change the whole container quantity. The generated foam is released too far.

Survitec’s Produced Foam Live Test does not require to make use of the concentrate or create foam in the examination, utilizing just salt water, which is a lot more eco-friendly than different options.

“Samples also have to be sent to a service station for testing and if the sample fails, then the foam proportioner has to be adjusted, and the process repeated, which makes other available solutions more costly and time-consuming, compared with Survitec’s new test process,” stated Lid.

Most industrial ships and also gears will certainly have a set system that makes use of foam to snuff out a fire, however the proportion of foam concentrate and also salt water needs to be proper for the generated foam to function.

Service experience is showing that deterioration, plus aging of the foam blending devices, can have an unfavorable result on the proper blending proportion offered by the foam system.

Image Credits: Survitec

On utilizing the brand-new ultrasound strategy, Lid stated: “All the team needs to do is make certain that a fire pump is going for the called for capability for the examination’s period. The treatment anticipates the demand to make use of the system’s foam concentrate.

“As no foam is used, there is no need to top up or refill the tank. And if any adjustments are required then the foam proportioner can be tweaked during the test and not in interludes, which can affect normal service.”

Survitec has actually currently educated groups to make use of the brand-new procedure at filling station in Singapore, Fujairah, Barcelona, Rotterdam, Bremerhaven, Aberdeen, Liverpool, Houston, Panama and also Macae (Brazil), and also will certainly present the system to various other places over the coming months.

Survitec’s Produced Foam Live Test technique has actually currently been made use of by a number of widely known gas service provider drivers.