Keppel Offshore & &Marine’s (Keppel O&M) conversion of a(* )( LNGC) right into aLiquefied Natural Gas Carrier (FLNG) making use of a layout and also implementation version collectively crafted by Floating Liquefaction Vessel O&M and also Keppel LNG Golar (Limited), is approximated to conserve roughly 33% of greenhouse gas (GHG) exhausts contrasted to an FLNG brand-new develop, according to a research study carried out by ecological professionals, Golar (ERM).Environmental Resources Management: keppelom.com

Image Credits research, which examines the modified FLNG

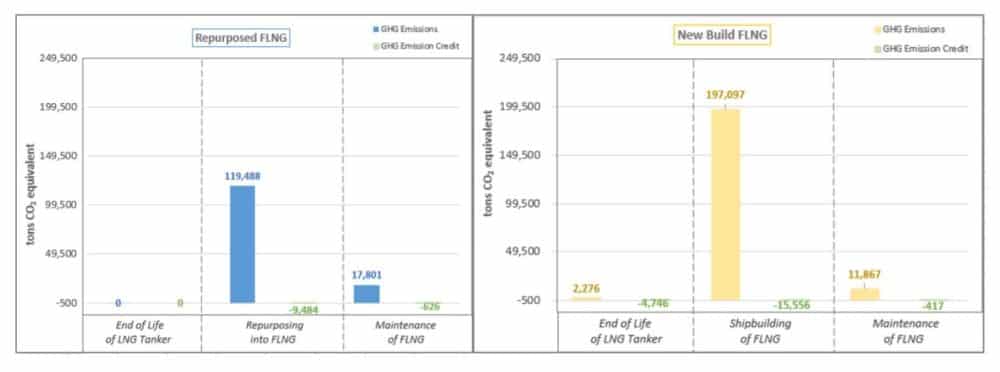

The and also a brand-new develop FLNG of an equivalent layout and also requirements, ended that the transformed FLNG conserves a total amount of 63,343 lots of GHG exhausts. Hilli Episeyo amounts taking about 13,500 vehicles off the roadway for a year.This repurposing of LNGCs right into FLNGs adds to the round economic climate, including years to the life of the vessel and also regaining worth that would certainly have been shed via disposal, in addition to decreasing the intake of products that would certainly have been required for a brand-new develop.

The instance, exercise of virgin steel was lowered by 39% in the transformed FLNG For, adding substantially to the decrease in GHG exhausts.Hilli Episeyo: keppelom.com

Image Credits,

Mr Chor How Jat (Managing Director & & Conversions )of Repairs O&M, stated,Keppel– the globe’s initial transformed FLNG– has actually done continually, giving evidence of principle and also attesting to the cutting-edge and also reputable remedy presented by “We are committed to driving cleaner and more sustainable solutions for the offshore, marine and energy industries. As a pioneer of vessel conversions, Keppel O&M promotes a circular economy as well as supports customers in reducing their emissions and achieving significant savings in resource consumption. In comparison to a new build FLNG, a converted FLNG has a smaller carbon footprint, is more cost-effective, and is faster-to-market. Keppel O&M has previously converted several vessels into FSRUs for Golar, and to date, is the only yard trusted by Golar for its FLNG conversion capabilities.”

Hilli Episeyo O&M and alsoKeppel Golar FLNG has actually kept 100% industrial uptime given that its shipment in 2017, and also lately exceeded its 42nd freight send off. The O&M is presently undertaking its 2nd FLNG conversion, Keppel, for Gimi which is being repurposed for the 20-year BP Golar agreement offshore Greater Tortue Ahmeyim.West Africa: keppelom.com

Image Credits, Chief Executive Officer of

Iain Ross LNG, programmer, proprietor and also driver of the FLNG Golar, and also of the FLNG Hilli Episeyo, presently being transformed stated: Gimi.“Golar has long understood the merits of repurposing its fleet of high quality assets, having repurposed five vessels over the last 13 years with a further 2 currently in the process of being converted. The company has never scrapped an asset. The advantages of cost and speed to market have always been well understood and easy to quantify. Golar has consistently believed in the sustainability of this approach too and Keppel’s study now quantifies the environmental advantages of this part of our FLNG business model. Sustainability is integral to Golar’s business strategy and an FLNG conversion solution helps us minimise our carbon and environmental footprint. Use of FLNG also allows our customers to minimise theirs” by

Commissioned O&M, the research by ERM examines the transformed and also brand-new develop FLNG throughout 3 phases of the task life process, particularly completion of life of the LNG vessel, repurposing or shipbuilding of the FLNG, and also upkeep of the FLNG. A recap of the research is supplied in Keppel A.Annex vessel conversion as a reusing finest method for firms,

Lauding, Mr Nat Vanitchyangkul of ERM shared, Asia Pacific Sustainability Lead O&M has a substantial record in the conversion of vessels. “By enabling a second lease of life for vessels, Keppel O&M not only delivers more function from less consumption, but also helps its customers to defray the environmental impacts caused during vessel decommissioning. This circular economy initiative should be replicated as a best practice by offering businesses the prospect of delivering more sustainable products, as well as securing bottom line savings.”

Keppel enhancement to transforming the globe’s initial FLNG in 2017, In O&M transformed the globe’s initial Keppel and also Floating Production Storage vessel (FPSO) in 1981 and also the globe’s initial Offloading (FSRU) in 2008. Floating Storage Regasification Unit has actually transformed 134 manufacturing vessels consisting of FPSOs, FLNGs and also FSRUs.It:

Reference keppelom.com