Korean Register Successfully Creates 3D Model Of Vessel In Real Time With NAPA

The Korean Register (KR) as well as NAPA, a leading maritime software application, solutions, as well as information evaluation company have actually effectively developed a ‘Live Interface Function’ for their corresponding software application KR SeaTrust-HullScan as well as NAPA Steel, permitting the real-time synchronization of a ship’s architectural information from the NAPA software application to KR’s SeaTrust-HullScan.

KR SeaTrust-HullScan is a technological software application that does an architectural evaluation of oil-tankers as well as mass providers using the typical architectural regulations, along with for container ships, LNG providers, as well as FPSOs. It is extensively utilized in both residential as well as international maritime sectors, specifically by shipyards as well as research study institutes.

NAPA Steel is a 3D CAD/CAE system established by NAPA, the industry-leading maritime software application firm. It is a thorough device for making, watching as well as examining 3D layouts, allowing developers, designers as well as category cultures to rely upon a solitary resource of reality. 3D model-based authorization likewise unlocks to better use electronic doubles for property life-cycle monitoring, where real-world information can be contrasted versus an online design of a ship, as well as the other way around, to recognize issues as well as confirm efficiency information. As an outcome, it is extensively utilized on the planet’s leading shipyards, consisting of the huge 3 shipyards in the Republic of Korea.

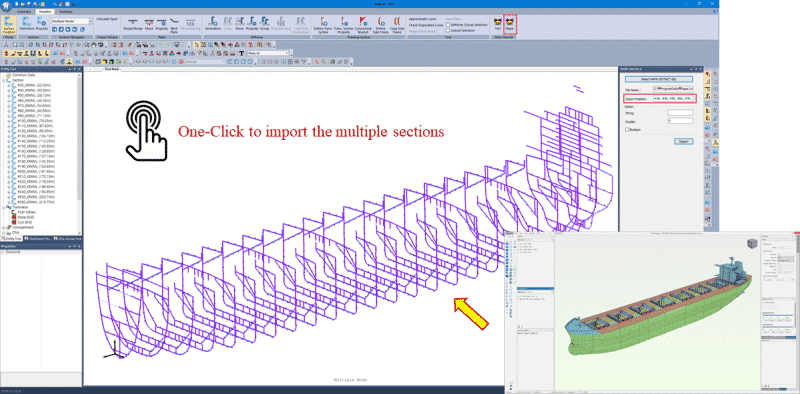

SeaTrust-HullScan imports information of the ship’s several areas from NAPA Steel with one click

Most shipyards utilize the NAPA Steel to create ships and afterwards utilize SeaTrust-HullScan to examine whether the ship layout follows the ship category’s regulations as well as to acquire authorization. The information generated in this procedure is taken care of in a distinct data style appropriate per software application specifically, so in order to import the information utilized in NAPA Steel right into SeaTrust-HullScan, customers have to transform it right into the style essential for SeaTrust-HullScan.

However, currently the brand-new real-time user interface feature can share NAPA Steel’s 3D design information which is utilized to analyze the regulation scantling of a ship in genuine time with simply one click of a switch to SeaTrust-HullScan, substantially lowering the moment invested in making as well as the opportunity of mistakes.

In enhancement, it can import the information on SeaTrust-HullScan in genuine time without running NAPA Steel or making use of an added data, providing better benefit contrasted to various other affordable programs.

“This live interface function jointly developed with NAPA can share accurate information from NAPA Steel in seconds, with a single click. This is a dramatic improvement on the previous arrangement which took several hours to input data to SeaTrust-HullScan. We expect that this significant advance will make SeaTrust-HullScan even more popular with users, while contributing to productivity and quality of ship design,” stated Daeheon KIM, the Executive Vice President of KR’s R&D department.

Yongsook LEE, the taking care of supervisor of NAPA Korea included: “NAPA has long pioneered the shift from 2D to 3D in design and approval. This co-development was implemented to realize the technical developments required to give users of KR and NAPA software the real benefits in assessing the scantling of a structure via 3D models – finally making 3D model-based approval (3D MBA) a reality.”

KR as well as NAPA think that the 3D model-based authorization (3D MBA) innovation can be established better as well as are currently functioning to broaden the user interface location to the factor where information can be traded equally in between the software application.