After 100 days of VLSFO procedure, LUKOIL Marine Lubricants is sharing current experience on VLSFO procedure with NAVIGO MCL Extra (40BN). This makes use of knowings over the previous couple of months along with experience from the shift from HFO to distillate gas in 2015 with NAVIGO MCL Ultra (20BN).

Using the best cyndrical tube oil, such as NAVIGO MCL Extra with added detergency, is just the very first step to prevent too much lining endure VLSFO. Feed price optimization is just as crucial permanently engine problem, in mix with engine examinations and also keeping track of the wear steel material of drainpipe oil examples.

The feed price optimization procedure includes Cylinder Scrapedown Analysis (CSA) at routine periods, offered by LUKOIL as component of their OPTIMIZE program. The switch over to VLSFO or in between various VLSFO blends can still be tough and also calls for mindful interest.

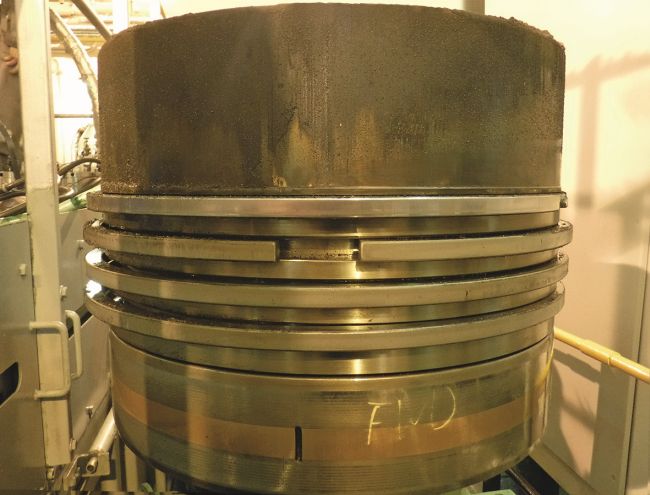

NAVIGO MCL Extra reveals exceptional piston tidiness on E.R. TALINN at end of test assessment|Image Credits: LUKOIL Marine Lubricants

Cat penalties, asphaltenes and also gas instability

The gas that drivers are switching over from, the brand-new gas and also just how the shift is taken care of all play a significant duty in guaranteeing a smooth transition. HFO is secure since it includes several polar hydrocarbons. Distillate gas are non-polar and also can create instability in mixes. Many ULSFO and also VLSFO blends are such mixes. When transforming over from HFO to these gas, the sludge, asphaltenes and also feline penalties which might have collected in time while on HFO can continue to be on the container base and also wall surfaces or in the gas system unless these are completely cleaned up or purged as it was suggested prior to the shift to VLSFO.

This concern can be worsened since the capability of extracts, ULSFO and also VLSFO to take in feline penalties and also asphaltenes can create them to be performed to the filter, cleanser and also engine. Cat great degrees at the inlet to the major engine should be listed below 15 ppm, preferably listed below 8 ppm. Some ULSFO and also VLSFO are treated with ingredients to boost their security, however these additional boost the gas’s absorbance and also should be taken care of with treatment.

Mixing gas can create issues because of conflicts which can not be totally prevented. Measures to handle this danger consist of; setting apart the gas top qualities, lessening blending and also keeping track of filter, cleanser and also engine problem. Engine surveillance consists of, as an example, routine examinations and also readjusting the feed price where essential, along with routine lab evaluation of scrape down examples.

Liner and also ring problem

Some 100 BN cyndrical tube oils, such as NAVIGO 100 MCL, deal enhanced detergency. Therefore, in many cases high BN cyndrical tube oil is made use of momentarily to combat down payments in the engine. In the long term, nevertheless, making use of too much BN with VLSFO will certainly result in down payments in the piston leading land and also ring pack, which can eventually result in scuffing and also, subsequently, loss of linings and also off-hire of the vessel. By comparison, NAVIGO MCL Extra has detergency equivalent to a 100 BN cyndrical tube oil however a reduced alkalinity or neutralization capability (BN). This maintains the engine devoid of down payments without the dangers of too much BN. An adequate feed price is called for to stop scuffing.

Another danger pertaining to making use of high BN cyndrical tube oil continually for VLSFO procedure is that it will certainly transform the surface area framework of the lining and also combat the regulated deterioration that GUY prefers in order to maintain the surface area harsh. In this circumstance brand-new rings are called for to decrease the danger of scuffing. Extensive tests and also keeping track of have actually revealed that NAVIGO MCL Extra gives outstanding scuffing resistance, however there is a restriction to what can be accomplished by lubrication. Hence, ring problem is seriously crucial. Cermet finishing gives enhanced messing up resistance. The density of the cermet finishing should be checked and also the rings should be changed prior to getting to the vital worths specified by the OEM, as GUY describes in its Service Letter SL2019-685 and also WinGD’s ‘Guide for judging condition of relevant piston-running components’.

A lining that has actually experienced messing up requirements to be machined or traded, since the resulting difficult surface area can not recuperate. In this situation, trading just the piston rings will certainly want, since the surface area framework of the lining would certainly still be brightened and also incapable to give sufficient lubrication.

Cylinder oil feed price

An optimum feed price is constantly far better than a too much feed price. However, because of the surface area framework of the lining and also the ring finishing, VLSFO procedure can be contrasted to a continuous running-in procedure. Running- in is one of the most vital procedure setting for an engine and also a boosted feed price is called for to boost the oil movie density and also decrease the danger of scuffing. Hence, each engine should be reviewed separately and also the problem of linings and also rings determines the called for feed price. For instance, mini seizures in the lining suggest a raised danger of scuffing and also the requirement for a greater feed price. At a supported problem, the feed price can after that be slowly enhanced while very closely keeping track of the engine problem

It is likewise essential to take into consideration possible loss of effectiveness in old, used lubricators. These could not maintain the anticipated feed price and also the resulting discrepancy is extra vital on VLSFO after that it might have gotten on HFO. An inadequate feed price and also BN while on VLSFO can likewise result in cool deterioration and also resulting high wear.

Fuel shot high quality

If an engine is not geared up with a piston cleansing ring or mini-sac nozzle (FAST or slide-valve nozzle), raised fouling of the exhaust gas and also piston running elements, such as leading land, might result in oil movie disruption and also eventually messing up.

Scuffing begins on top dead facility where the piston has absolutely no rate. If surface area roughness is reduced, there will certainly be much less oil readily available and also unpleasant wear will certainly begin there. The kind and also problem of the ring finishing in mix with a greater feed price aid to combat this procedure, however it is very important to utilize reduced BN cyndrical tube oil enhanced for VLSFO procedure such as NAVIGO MCL Extra.

Scuffing avoidance

An raised feed price is likewise called for to clear out wear bits to stop additional unpleasant wear by the piston ring. This approaches the running-in procedure and also should not be puzzled with the function of the cyndrical tube oil’s detergency. The oil’s detergency maintains the ring groove and also rear of the ring tidy and also devoid of down payments to make sure that the ring can relocate easily. If ring activity suffers, the tons on the ring rises therefore does the danger of scuffing. The right feed price and also BN degree of a cyndrical tube oil with reduced alkalinity however raised detergency is required to maintain lining, piston and also ring pack tidy and also with regulated wear degrees.

Follow OEM suggestions

Generalizing high feed prices as unsafe is inaccurate and also might also threaten for sure engines. We very advise complying with OEM suggestions and also lubricating substance suppliers’ recommendations in any way times.