No Harm No Foul: Marine Coating Draws Copper From Seawater

Australian scientists are readied to check an aquatic covering that can occupy copper from salt water and also launch it making use of electric pulses to avoid the development of undesirable microorganisms on ship hulls.

Australian scientists are readied to check an aquatic covering that can occupy copper from salt water and also launch it making use of electric pulses to avoid the development of undesirable microorganisms on ship hulls.

The $350,000 job will certainly carry out a collection of sea tests in the following one year and also is being led by Flinders University in South Australia in cooperation with the University of South Australia, shipbuilder ASC and also the Australian Department of Defence.

Image Credits: theleadsouthaustralia.com.au

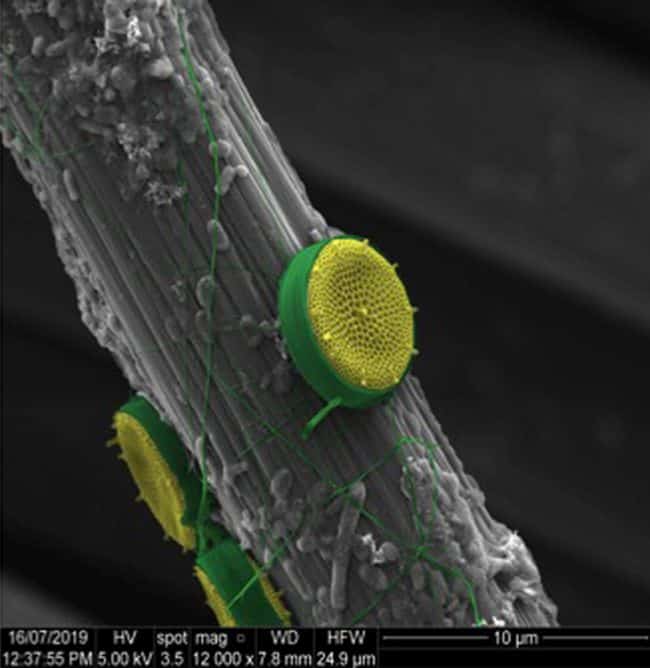

Fungicide paints that launch copper right into the water to exterminate natural development such as algae and also barnacles from ship surface areas are one of the most frequently made use of antifouling coverings. However, this has actually resulted in ecological problems concerning the enrichment of copper in the water in harbours all over the world.

Alternative silicon-based coverings have actually shown to be reliable at getting rid of algae and also various other microorganisms when watercrafts get to a particular rate however are pricey and also inefficient at stopping accumulation on vessels anchored in port.

Flinders University scientists have actually invested 4 years establishing a chemically crafted carbon-based covering that can attract copper ions from sea water and afterwards launch them making use of electric pulses.

The most current job, which is being partly moneyed by a $150,000 give with the South Australian Government’s Defence Innovation Partnership, will certainly check the brand-new covering in the aquatic setting. A 2nd covering that utilizes just electric pulses to eliminate fouling will certainly likewise be checked.

Image Credits: theleadsouthaustralia.com.au

Flinders University Biofilm Research and also Innovation Consortium Professor Mats Andersson stated the size of each cycle would certainly likewise be checked to develop the optimum timings.

“You wait for some time for it to take the copper up from seawater and then you stimulate it with electricity to release the copper, then you take it up again and release it so it is a closed cycle,” Prof Andersson stated.

“When the copper is launched it eliminates the microorganisms basing on the hull of the ship.

“We have done initial studies and seen that it works but we don’t know if the cycle should be 10 minutes, one hour or one day so that is one thing we need to test as part of the trial.”

Hull fouling can trigger loss of rate and also manoeuvrability, rise gas usage, hull damages and also positions a biosecurity hazard of condition spread.

New Zealand was the very first nation to present challenging nationwide biofouling policies in 2018 to shut out international water illness and also intrusive aquatic microorganisms. Other nations are readied to comply with New Zealand’s lead. At the very same time, using standard copper-based antifouling paints is under higher examination than ever before due to contamination problems and also the prospective influence it can carry indigenous aquatic microorganisms.

The screening in South Australia will certainly include 20cm by 20cm steel discount coupons treated with the covering and also positioned in salt water for concerning 2 months. Coupons with simply the electrochemistry therapy however without the copper launch will certainly likewise be made use of to properly supply an electrical shock to the microorganisms.

“We want to try a few different formulations and then by itself to see how much we can prevent and how efficient the electrochemistry alone is at preventing the growth because we have seen that work without the copper release,” Prof Andersson stated.

“We don’t know if it is as effective yet but we have seen it in small trials in fish tanks in the lab and it seems to work.”

The innovation is still in model phase however Prof Andersson stated the end product had international prospective if it gets to complete commercialisation.

“It’s definitely a big market because it’s still a major problem,” he stated.

“The discussion around the problem has been going on for 10-15 years but there have been no good or realistic solutions.”

Defence is a companion in the job and also will certainly be seeking to possibly utilize the covering as component of its $50 billion strategy to restore the Royal Australian Navy.

This consists of the building and construction of 9 Hunter course frigates and also 12 Attack Class submarines to be developed at the Osborne Naval Shipyard in Adelaide, which is undertaking a $500 million upgrade.

The anti-fouling covering job is among 4 South Australian jobs moneyed with the current round of the Defence Innovation Partnership.

Defence SA Chief Executive Richard Price stated South Australia’s 3 colleges each had certain staminas in a series of defence-relevant areas.

“We are applying this capability by connecting these researchers with our defence industry to accelerate development and build solutions to key projects for Australia,” Price stated.

“The importance of collaboration between defence industry and researchers cannot be understated; it is the foundation for success and key to solving increasingly complex Defence problems.”

Reference: theleadsouthaustralia.com.au