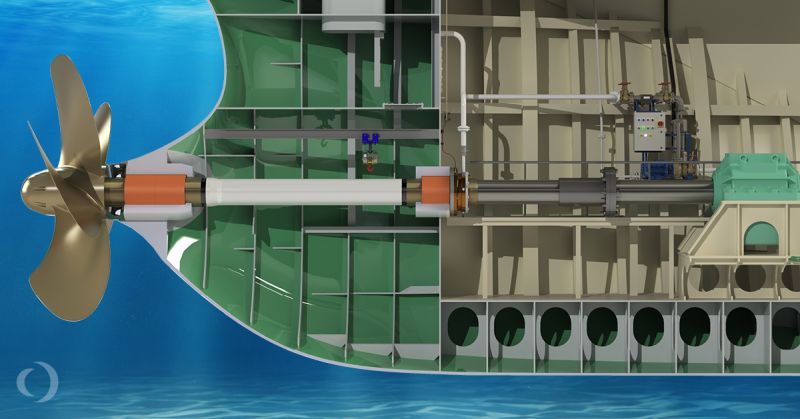

Ship proprietors, drivers and also supervisors replying to an ecological study executed by Canadian based McMaster University’s DeGroote School of Business have actually recognized the demand to lower functional oil leak from prop shafts. But an absence of comprehending concerning cleaner options is stopping any type of significant technical modification.

Researchers wondered about greater than 1000 aquatic sector experts in 2015 to much better recognize why most of newbuild ships remain to be fitted with obsolete oil lubed prop shafts when verified, cleaner modern technology is commonly readily available.

Dr Ken Deal, Professor of Marketing, DeGroote School of Business, McMaster University, claimed: “The DeGroote School of Business works closely with organizations to provide practical experiential learning for students. The survey, designed to better educate the shipping industry’s decision makers, provides a good example of how academia and business can work together to help different industries achieve their environmental goals.”

McMaster University, component of the U15 Group of Canadian Research Universities, determined a huge void in understanding concerning salt water lubed systems.

According to the searchings for, while 74% of the participants thought “oil leaking from the stern tube negatively affects the environment”, actions suggested an absence of understanding concerning the expenses, advantages, dependability, technological equivalence, and also efficiency facts of an open salt water lubed prop shaft bearing system.

Of all the 25 concerns postured, one of the most telling indicator regarding why shipowners remain to define oil-lubricated systems was amassed from inquiry 6:“how important are the following factors when choosing an oil lubricated system over a seawater lubricated system for your fleet?” Variations of “it works, so why change it,” composed most of solutions.

Jeff Tennebaum, Marketing Manager, Thordon Bearings, that prompted the research study, claimed: “Many of the respondents were not fully aware of the problem. They obviously care about the environment, but the results suggest they may not consider a stern tube oil leak to be a significant source of pollution.”

When individuals were asked just how much they concurred or differed with a collection of declarations connecting to efficiency, there seemed a misunderstanding that salt water lubed prop shafts were not as verified as oil lubed systems. Respondents were not aware of the technological developments salt water lubed prop shaft bearing systems have actually transformed the years.

“The problem with seawater lubricated shafts is that we have to withdraw them every 5 to 6 years. If that is solved, then I would prefer them over the oil lubricated shaft,” claimed an additional participant.

“This [oil lubrication] is the industry standard”“Mostly due to what’s offered by the yard” “It was never proposed by any newbuilding shipyard”. “Shipyards are reluctant to change to a water lubricated arrangement”, were simply a few of the study actions.

Craig Carter, VP Business Development, Thordon Bearings, claimed: “An prompt rise in ship proprietors requiring water oiled systems would gradually pivot the instructions of the worldwide delivery sector in the direction of a far more eco lasting, absolutely no air pollution future; one that remains in line with the United Nations Sustainable Development Goal # 14 and also with the IMO’s World Maritime Theme for 2022– New innovations for greener delivery.

“We are dissatisfied, obviously, that the ‘if it works, why change it’ way of thinking lingers yet we will certainly attend to these concerns with a collection of academic video clips, workshops and also workshops.

“It is absolutely crucial that Thordon Bearings and other manufacturers continue to educate the industry about the advantages of an open seawater lubricated system as way of meeting sustainability targets, but regulatory authorities also have an important role to play.”