An ABB research based upon 3 years of functional ship information installs an instance for incorporating battery power onboard modern-day icebreakers, composes Samuli Hänninen, that concentrates on icebreaking vessels at ABB Marine & &Ports

The maritime market is still at the developmental phase of understanding the gains readily available from batteries, yet the capacity to scale approximately megawatt-hour degrees is not the only tourist attraction for the zero-emission modern technology. Evidence recently revealed by ABB recommends that the enhancements made to power effectiveness and also responsiveness can make a definitive distinction for the efficiency of icebreakers running in severe problems.

Demanding high set up power, icebreakers must additionally be reliable throughout a broad variant in power requirements, particularly considered that they run in locations where discharges deal with specific examination. However, traditionally the demand for high vibrant tons is satisfied by oversizing generators operating on nonrenewable fuel source– an option which is very ineffective when engine tons are reduced.

Slow tons ramping is additionally an usual trouble for diesel motor, while brand-new generation LNG engines are also much less receptive. At the propulsion controls, icebreaker drivers are usually all set to react yet left waiting on engines to increase. Time delays similar to this can urge what some call a conventional method to procedures, and also others call out as ineffective: if an engine takes 10 mins to heat up to one hundred percent power, staff operating at tons in the margin in between 2 and also 3 engines will certainly like to run continually on 3.

Battery power combination by ferryboat and also cruise liner proprietors provides solid advice en route quickly readily available saved power can boost the efficiency of various other ship source of power by helping peak shaving or rotating book, along with supplying a zero-emission power option. Understandably, newbuilds represent the substantial bulk of battery setups to day, yet the variety of cruise ship, ferryboat and also freight ship retrofit tasks is expanding.

Cold Hard Evaluation

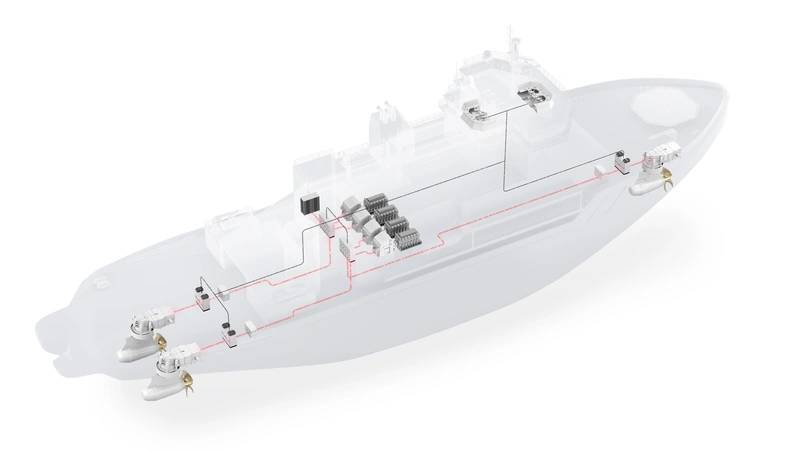

As among the leading firms driving sea-going battery power, ABB has actually assessed the effect of mounting a power storage space system (ESS) onboard icebreakerPolaris Delivered in 2016 yet still among one of the most sophisticated icebreakers worldwide, Polaris was the initial ship in its course to operate on dissolved gas (LNG), driving 4 Low Pressure Dual Fuel (LPDF) engine driven gensets. The vessel is possessed and also run by the Finnish state-owned business and also has actually integrated electric nuclear power plant outcome of 22.5 MW.

Like numerous icebreakers prior to it, Polaris includes an Azipod propulsion system from ABB– in this instance 2 6.5 MW demanding devices and also one 6 MW bow device from the Azipod VI item household varying from 6-17 MW, established and also customized for icebreaking vessels. The high torque induction electric motors in the propulsors include a straightforward and also sturdy building and also can provide up to 180 percent of over torque, making sure that the prop turns also throughout the heaviest ice communications.

Plug- in Simulation

Using information attracted from 3 complete winter running in the Bay of Bothnia, ABB’s Polaris research establishes a brand-new criterion in reviewing the effect of ESS modern technology on a brand-new ship kind.

With a general goal of imitating a battery system that can soak up big tons variants, to boost gas effectiveness and also ramping ability, ABB posted powerplant tons account information from genuine procedures in ice to a MATLAB data. The version assessed the effect of an ESS Installation on overall greenhouse gas discharges, mostly CH ₄, along with decreasing gas intake and also enhancing the vibrant efficiency of the system.

The version functioned utilizing a hybrid power system that was streamlined in contrast to genuine procedures onboard Polaris, to contain 4 major generators (complementary generator was omitted), one 4.5 MWh and also one major system tons, with the battery to be billed from the generators. The dual-fuel engines were substitute to run in gas setting or in diesel setting, with experience-based presumptions made on lowered engine effectiveness at reduced tons. A direct relationship in between tons changes, gas effectiveness and also CH ₄ discharges was additionally presumed.

Based on an account that saw Polaris mixed-up for 4 successive weeks, around 4,000 hrs of procedures were designed over a 28-month duration.

In the unscientific instance offered, a traditionally powered ship operating in ice-infested waters and also running at tons at the margins in between 2 and also 3 engines was preserved on 3 engines, based upon the preventive concept. However, the immediate accessibility of extra power from a 4.5 MWh ESS suggests space for manoeuvre. The ESS will certainly supply instant propulsion power to cover the moment it considers extra major engines ahead online, as an example.

In the circumstance offered, risk-free procedures must be feasible for even more of the moment with 2 engines on the internet supplemented by top tons battery power. From the Polaris simulation, ABB recommends that the instant accessibility of power as required would certainly minimize major engine use hrs by approximately an extremely significant 46 percent of on the internet time, with ensuing gas and also discharges financial savings, and also various other knock-on advantages for upkeep and also through-life price.

Icebreaker Moves Ahead

Together, the operating account and also assumptions on ecological impact make the vessel kind the optimal prospect to make use of the top loading, rotating book and also zero-emission power abilities readily available with incorporating batteries right into propulsion. For LNG, ABB’s simulation recommends that consisting of the ESS onboard Polaris would certainly lead to a 38 percent CH ₄ decrease, 16 percent much less gas intake (based upon 46 percent decrease in engine hrs); for diesel, the outcome is a 10 percent decrease in gas intake, 36 percent decrease of engine hrs.

By being a lot more receptive to power tons requires, the enhancement of the ESS will certainly additionally boost the icebreaker’s general safety and security margin: an icebreaker engine functioning to get rid of an ice ridge can be subjected to unexpected over torque problem, as an example; the power ramp with an onboard ESS-equipped vessel disappears than 10-12 secs.

Despite the constraints of the version, ABB wraps up that it appears from the simulations that mounting a battery can play a favorable duty in the power system of ships likePolaris As well as decreasing the variety of engine running hrs, the details instance highlights that using batteries would certainly additionally cause a decrease in the methane slip.

In enhancement, incorporating battery power might be a path to widening the safety and security envelope of icebreaking in such a way that can permit lowered set up power/number of major engines. It might be said that, if a lot of circumstances calling for complete in advance power are fairly brief in period, it would certainly be practical to boost the ability of the ESS and also eliminate one major engine. In some applications, ABB thinks this deserves refresher course.