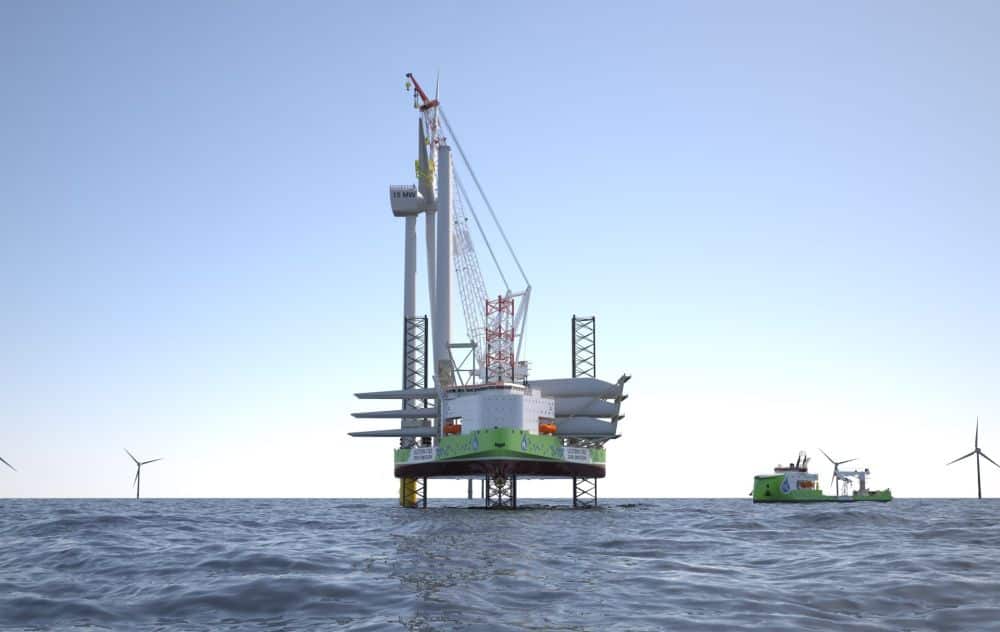

Zero-Emission Turbine Installation Becomes Today’s Reality

Ulstein’s 2nd hydrogen crossbreed layout for the overseas wind sector, the ULSTEIN J102 zero-emission wind generator setup vessel (WTIV), can run 75% of the moment in zero-emission setting. Using easily offered innovation, the added expense is restricted to much less than 5% of the overall CAPEX.

Most brand-new jack-up styles are including a battery crossbreed system along with diesel gen collections, with a future alternative for hydrogen-powered gas cell systems. The drawback nonetheless of a high-power battery power storage space system (BESS) is its heavyweight as well as expense. That is not advantageous for a WTIV layout, where weight cost savings are necessary for reducing Elevated Weight as well as maximizing the Variable Deck Load.

Image Credits: ulstein.com

Taking the sector from hydrogen prepared to hydrogen-powered

Rather than to go with innovation to be developed to excellence as well as make a style that is gotten ready for future hydrogen-powered gas cells, Ulstein has actually taken the pragmatical, yet practical technique. ‘We have carefully analyzed the operational cycle of WTIVs and looked at the power demand in the various modes of operations’, claims Ko Stroo, Product Manager atUlstein ‘This analysis showed that ca. 75% of its time, a WTIV is in jacked-up position performing crane operations. Using a combination of a hydrogen fuel cell system and a relatively small battery energy storage system (BESS) is then sufficient to meet the overall power demand on board and crane peak loads.’

Attractive organization situation for wind turbine setup vessels

‘The same design philosophy as on our first hydrogen powered SX190 design, resulted in a much more attractive business case when applied to a turbine installation vessel’, states Edwin van Leeuwen, handling supervisor of Ulstein’s Rotterdam layout workplace.

Image Credits: ulstein.com

The hydrogen crossbreed system of the ULSTEIN J102 layout has actually been established in such a method, that future advancements in hydrogen innovation can conveniently be suited the vessel without significant alterations. ‘The limited availability of hydrogen bunker infrastructure in ports is often seen as a major hurdle. With our modular storage lay-out, we want to break the chicken and egg dilemma’, proceedsStroo ‘It creates flexibility to operate the vessel worldwide, even when bunker infrastructure is not yet present.’

‘The strong focus on renewable energy and emission reduction to meet worldwide climate goals should also be reflected by investments in cleaner operations when installing offshore wind turbines’, claims Edwin vanLeeuwen ‘Hydrogen is one of the most promising zero-emission fuels for offshore vessels and we want to be leading in developing sustainable ships.’

Main functions of ULSTEIN’s J102 hydrogen-hybrid zero-emission layout are:

- CARBON DIOXIDE decrease each year: 4,000 mt

- Emission decrease per setup cycle: 25 %

- H2 gas cell system: PEM gas cell

- H2 storage space system: 7 x 40ft containers pressed H2

- Battery power storage space

Reference: ulstein.com