Covington, La. based mostly marine engineering and companies agency Baker Marine Solutions (BMS) has unveiled a brand new pipe mill barge idea design focusing on uptake within the U.S. offshore wind trade.

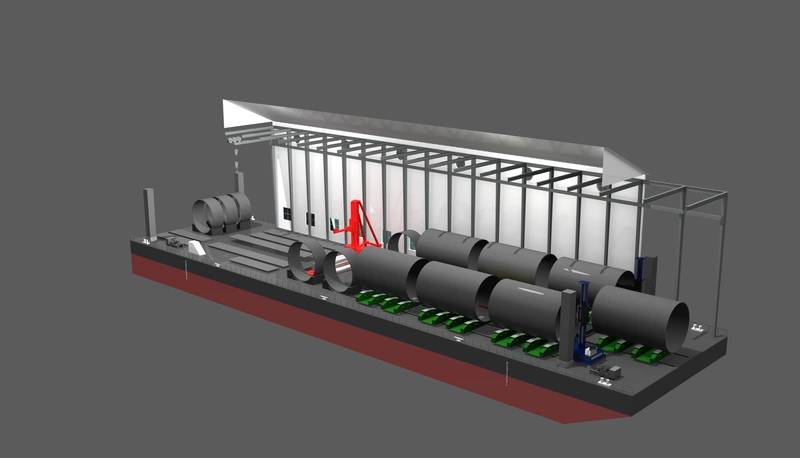

BMS describes its new 1888 Mobile Pipe Mill Barge idea as a solution to the trade’s monopile availability challenges and lack of ample yard area for fabrication.

The BMS 1888 supplies a cell pipe mill facility that may be scaled to satisfy the necessities of any particular challenge, wherever on the coast, BMS stated, noting that the barge can be supposed to hurry up the initialization of the challenge, as the ability may be moored wherever with acceptable water depth and peak clearance.

Should obtainable shoreside amenities not be obtainable, the 1888 can be mated as much as extra cell welding and coating amenities barges, making a full scale manufacturing line that may be quickly mobilized to any space that may accommodate the marine footprint.

“The U.S. offshore wind market will require forward looking, practical solutions to complex supply chain challenges. The 1888 concept meets this goal,” stated BMS president Jim Baker.

The 1888 shall be fitted with two lengthy seam weld stations, a curler arm, three welding manipulator-arms for 10-foot rolled plate, two stabbing stations, two stringer weld stations, two again weld stations, two welding manipulator-arms for again weld, an overhead bridge crane and gantry system, and 4 60-foot spuds. It shall be able to producing 10- by 25-foot O.D. cans produced by lengthy seam weld, and 40- by 25-foot O.D. cans as a remaining product.

(Image: Baker Marine Solutions)

(Image: Baker Marine Solutions)