Offshore installment as well as deactivating specialist Allseas stated Tuesday it had actually efficiently eliminated as well as transferred to coast Repsol Norge’s 30,000-tonne Gyda system “in a matter of days.”

According to the firm, Allseas’ Pioneering Spirit, the globe’s biggest overseas building and construction ship, provided Gyda system’s 11,000-tonne coat to Aker Solutions’ disposal backyard in Stord, Norway, much less than 2 days after eliminating it from the southerlyNorwegian Sea

“The latest job for the vessel’s new jacket lift technology is one of the heaviest ever but well within the system’s 20,000-tonne lift capacity,” Allseas stated.

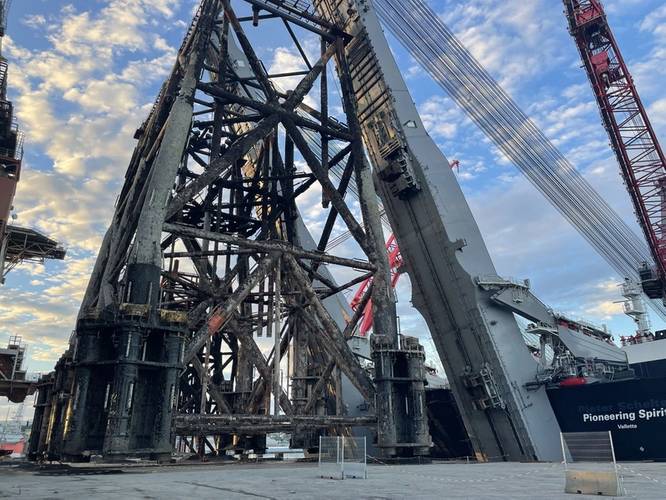

“This morning, the jacket was set down directly onto the quayside and reunited with its decommissioned drilling and production topsides, delivered by Pioneering Spirit in May this year. Aker Solutions expects to recycle around 98% of the facilities,” Allseas stated. As the coat was up and down produced as well as set up, the framework can not maintain filling in the straight setting throughout transportation. The remedy of transferring the coat in a near-vertical (60%) setting ©Allseas

As the coat was up and down produced as well as set up, the framework can not maintain filling in the straight setting throughout transportation. The remedy of transferring the coat in a near-vertical (60%) setting ©Allseas

To remind, the Pioneering Spirit last month removed the 18,400-tonne Gyda platform topsides from the Norwegian North Sea in a single lift, too.

“Our mission at Allseas is to remain a frontrunner in the offshore energy market by pioneering ground-breaking technology to meet the industry’s ever-changing needs,” statesAllseas President Edward Heerema

“The Gyda platform removal strengthens our reputation as a game changer in the industry. Again we have shown that Pioneering Spirit provides a significantly faster, safer, more efficient, and sustainable option for the removal and installation of offshore facilities.”

“Split across two campaigns to allow for the vessel’s busy schedule, Pioneering Spirit completed the removal, transport and load-in to the disposal yard of the entire Gyda platform, its 32 conductors and template in 12 days,” Allseas discussed.

To allow the elimination of the coat, the framework’s 24 structure heaps were reduced listed below the seabed degree. Main hoist obstructs put on hold from the Jacket lift system (JLS) light beams were attached to pre-installed rigging as well as the whole framework was raised as well as lined up with the training light beams.

“As the jacket was vertically fabricated and installed, the structure could not sustain loading in the horizontal position during transport. The solution of transporting the jacket in a near-vertical (60%) position, with interface supports and grillage, made delivery of the complete jacket to the yard possible,” Allseas stated.

Gyda is an area in the southerly component of the Norwegian industry in the North Sea, in between the Ula as well as Ekofisk areas. The area was created with mixed exploration, holiday accommodation, as well as handling center sustained by a steel coat standing in 66 m water deepness.

The system began generating in 1990, as well as a deactivating strategy was sent in 2016.