N’ brilliant declares its high-strength austenitic stainless-steels will certainly change the style and also building of onshore and also overseas oil, gas, and also LNG centers.

“The global demand for LNG is projected to reach 700 million tonnes per year by 2040 fuelling the need for greater LNG infrastructure including import receiving and export terminals, FLNG vessels, and LNG carriers. Since these facilities are being designed with larger capacities and operating under increasingly more challenging conditions, advanced materials technology is required to maximise performance, reduce carbon emissions and optimize through-life costs. Fortunately, an N’GENIUS solution is on the horizon,” the firm claimed.

N’ brilliant claimed its collection is a full “family” of high-strength austenitic stainless-steels that exceed 300 Series stainless-steels and also are an economical option to nickel-alloys.

“As with conventional austenitic stainless steels, the N’GENIUS Series has excellent ductility and toughness at sub-zero and cryogenic temperatures. But exceptionally higher strength and vastly superior corrosion resistance makes this new family an entirely different proposition,” the firm claimed.

The firm declares its “unique” style supplies design benefits for the onshore and also overseas sector.

“LNG piping systems, engineered products, fabricated products, and equipment can be developed and manufactured with reduced wall thicknesses, offering the potential to make products and equipment lighter and smaller, significantly reducing topside weight, and helping facilities overcome space and height restrictions. Any space savings would also improve accessibility regarding servicing and maintenance, repairs, upgrades, or replacement work on products and equipment in the future,” N’ brilliant claimed. © N’GENIUS

© N’GENIUS

“In particular, large facilities with extremely heavy topsides, including floating production storage offloading (FPSO) vessels, FLNGs and upstream fixed platforms, would greatly benefit from the design and construction advantages that the N’GENIUS Series can provide. This includes the potential to reduce the overall construction time and costs, as well as benefitting from easier handling and lower associated transportation costs,” the firm claimed.

Dr C.V. Roscoe, the innovator of the N’GENIUS Series, claimed: “Some of these larger facilities can have topsides weighing more than 50,000 metric tonnes, which has a major impact on the design and construction cost of oil, gas and LNG projects.

“The N’GENIUS Series has an infinite range of Alloy types, variants and grades and is perfectly suited for all the different material specifications, scopes of work and products including piping systems, pumps, valves, modules, vessels and tanks. Therefore, the potential to optimize the weight and space of all these components, and in turn reduce costs, could be invaluable. It really is the total system material.”

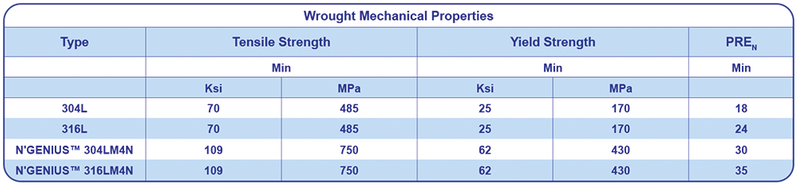

The weight-saving benefits provided by the N’GENIUS Series are achieved from superior wrought mechanical strength properties, the company says.

“For instance, the minimal return and also tensile toughness of the N’GENIUS 304LM4N and also N’GENIUS 316LM4N qualities are usually 2.5 and also 1.5 times greater specifically contrasted to the minimal toughness worths of standard 304L and also 316L. This makes it possible for the N’GENIUS Series to have substantially greater allowed style anxieties than standard austenitic stainless-steels,” N’ brilliant claims. < period course=" fr-inner" data-gramm=" incorrect" spellcheck=" real" wt-ignore-input=" real">©N’Genius

< period course=" fr-inner" data-gramm=" incorrect" spellcheck=" real" wt-ignore-input=" real">©N’Genius

Similarly, the company says, the higher minimum Pitting Resistance Equivalent (PRE) values for N’GENIUS 304LM4N and N’GENIUS 316LM4N grades compared to those for 304L and 316L produce significant improvements in localized corrosion and general corrosion resistance. This enables products and equipment to last longer, facilities to be designed for a longer service life, and projects made more sustainable and cost-effective.

“The N’GENIUS Series will certainly likewise aid speed up the broader application of carbon capture and also storage space (CCS) modern technology.Inevitably, the enhancement of onboard CCS for upstream dealt with systems, FLNGs and also FPSOs indicates added topside weight, quantity and also area. So a decrease in the weight and also dimension of onboard CCS systems, as might be accomplished with N’GENIUS, would certainly make this environment-friendly modern technology end up being much more viable and also play a basic function in driving down carbon discharges,” it says.

“The N’GENIUS Series can be produced in both functioned and also cast types, in a comprehensive variety of items for the oil, gas and also LNG sectors. These consist of pipeline, tube, installations, and also flanges for piping systems, components, warmth exchangers, umbilicals; and also line pipeline for risers, flowlines, pipes, and also manifolds. N’GENIUS modern technology can likewise be related to design items consisting of pumps and also shutoffs, made items such as vessels and also storage tanks, and also expert items, consisting of case and also tubes for Oil Country Tubular Goods (OCTG),” the firm clarified.