Warehouses in the olden days were made use of totally for the storage space of products. They were typically big structures situated near train joints, ports, or company centres.

These storehouses were provided on rental fee completely or partly for storage space of products, equipment, and so on with the client needing to prepare all tasks such as dumping, packing, as well as packaging of their freight.

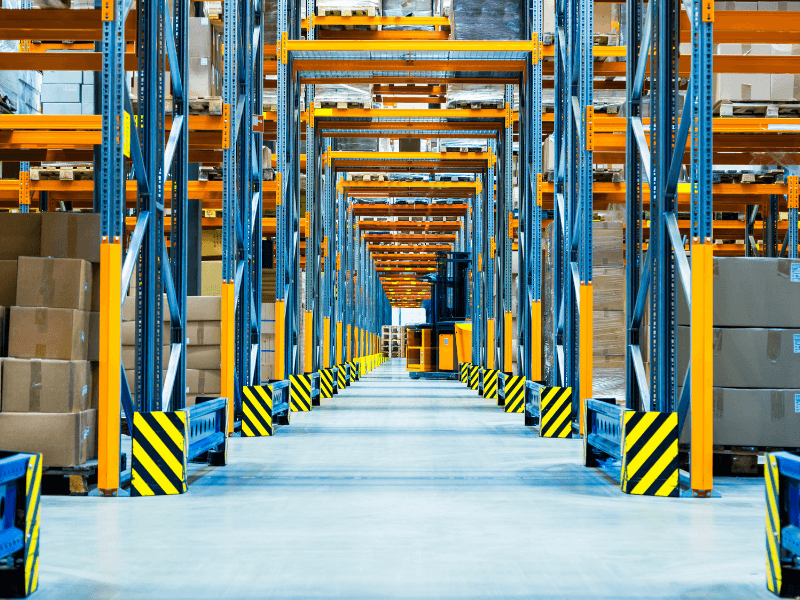

Gone are those days when a storage facility implied purely‘storage space only’ Most modern-day storehouses are building as well as technical marvels that satisfy mostly all the supply chain demands of its clients.

A supply chain consists of all the phases an item travels through, from its manufacturing up until it gets to the hands of completion client. Warehousing is an important component of the modern-day supply chain as well as logistics procedures. It is where a lot of the procedures occur.

According to 2020 information launched by the World Trade Organization (WTO), 17.5 trillion USD well worth of products were exported in between nations (this is USD 2 trillion much less compared to the numbers of 2019, as an outcome of the downturn in trading tasks brought on by the Coronavirus pandemic). As we can see, this does not consist of products offered within nations.

The supply chain of the products hence traded would certainly have included its storage space eventually in time. Imagine the storage facility facilities called for to hold as well as manage this monstrous amount of products!

Table of Contents

Are Warehouses Necessary?

The straightforward response to this isYes Warehousing of products comes to be a requirement as a result of the moment space in between manufacturing as well as need.

Even products that are made as needed need to be kept for a quick duration. The center to keep products enables business to create or produce their items beforehand to satisfy future needs.

For products with seasonal need, storage space is a requirement. They are created beforehand as well as warehoused to satisfy future need.

Economies of range need manufacturing in recommended multitudes that can not be offered to clients at one time. Such products need to be kept up until there is need for them. Temperature- managed storehouses satisfy the demands of keeping ambient, cool, or icy products.

Classification of Warehouses

Warehouses might be generally categorized as government-owned, possessed by exclusive business, or by cooperatives.

Bonded storehouses are either run by the federal government or accredited to exclusive drivers by the federal government. They enable storage space of products without needing to pay custom-mades responsibility up until these products are secured of the adhered storage facility.

Bonded storehouses are typically made use of for the storage space of high-value imported products such as alcohols, cigarette, specific electronic devices, and so on

Requirements of a Modern Warehouse

Besides a practical area, excellent availability by roadway, schedule of area, as well as the most recent product managing devices, a storage facility needs to be created as though invoice of products, evaluation, storage space, concern of products, as well as various other features can be done quickly.

To stay clear of traffic jams inside the storage facility, the Material Flow Planning (MFP) needs to be excellent. Material circulation might be intended, based upon the U-Flow or Through-Flow techniques.

In the U-Flow approach, products circulation in the form of ‘U’ via the storage facility. The invoice as well as send off of products occur at the very same side of the storage facility structure with the very same anchors being made use of to get in addition to send off products.

In the Through-Flow approach, products circulation from one end of the storage facility structure to the various other, frequently in a straight line. To streamline, products are gotten at one end of the storage facility, taken inside for storage space, selected, as well as sent off from the various other end.

The format of a storage facility needs to be intended correctly prior to building and construction, taking into account the adhering to major aspects:

- Fire- dealing with devices

- Sufficient spacing– aisles, flows, and so on

- Sufficient area to steer modern-day product managing devices.

- Ventilation as well as lights

- Heating as well as refrigeration systems

- Office area

- Provision for future development of the center

A great format style is vital for the optimum performance as well as area usage of a storage facility.

The Main Functions of a Warehouse

Warehousing is an essential element of any type of supply chain. Let us have a look at the major features of a storage facility that typically begins with the invoice of products.

Unloading

Goods are provided to a storage facility typically by roadway transportation. Such products are described asGoods Inward Whether it comes over freight ship, airplane, or products educate it needs to be relocated to a storage facility, nonetheless, shut it could be to the quayside, path, or train terminal making use of a vehicle or various other ideal car.

The procedures supervisor of the storage facility needs to intend as well as make certain that the sources as well as setups to get such products are made beforehand. This is called a Goods Inward Plan (GIP).

It might be essential for the storage facility to schedule the cars to change freight from the port, airport terminal, or train terminal. Staff to discharge the products internal need to be designated as well as the essential product handling devices offered.

Goods that have actually can be found in are unloaded at the storage facility as well as scheduled an examination.

Inspection

The storage facility procedures personnel need to make certain that what is revealed on the packaging listing is what is really gotten at the storage facility. The packaging listing as well as the billing need to likewise match. An items invoice evaluation consists of, however is not restricted to inspecting that the amounts are right, costs revealed are exact, which there is no damages to the products or damage in high quality when gotten.

Any errors or various other problems need to be recorded as well as given the interest of the procedures manager that would certainly after that take it to the interest of the supply management personnel. The supply management personnel educates the carrier, the carrier, or the insurance coverage agent of such problems.

Once dumping as well as evaluation of the products are finished the storage facility procedures personnel prepares an Inventory Receipt Report (IRR) by consignment. The IRR would certainly reveal information of the products obtained consisting of information of products obtained short, excess invoices, ran out or harmed products obtained, as well as various other such details.

Put- away as well as Storage

This is the phase when the products that are gotten as well as checked are relocated to their particular system assigned places on shelfs inside the storage facility. Very hardly ever is block-stacking complied with in storehouses nowadays.

In block-stacking, tons are put on the storage facility flooring as well as piled on top of each various other to a secure elevation. While it conserves area, it can be fairly troublesome to manage.

The IMS assigns places for the products inwards based upon put-away guidelines as chosen by the storage facility monitoring. Goods for put-away are typically recognized making use of universal product code. Bar codes are computer-readable. Bar code scanners transform the information right into legible details such as item as well as plan details, area, and so on

The IMS exercises a pattern of storage space whereby the kept products can be accessed quickly for later circulation based upon the concepts of FIFO (First In– First Out), FEFO (First Expiry– First Out), LIFO (Last In– First Out), and so on

Some storehouses make use of light innovation where a system-controlled light overviews the driver to the specific area to put the products. A Put- away record reveals the products that have actually been gotten right into the storage facility with their particular information as well as area in the storage facility.

Systems Receipt

Once the put-away of products is finished, the gotten amounts are approved in the storage facility Inventory Management System (IMS). The Stock Administrators of the storage facility are typically in charge of this. They will certainly make up the specific amounts obtained, at the agreed costs, thinking about brief invoices, harmed supplies, and so on

The outcome right here is typically in the kind of a Goods Receipt Note (GRN). Typically, with the concern of a GRN, the details products are offered in the computer system systems for re-distribution or sales.

Issue of Stocks

Stocks are released from a storage facility based upon orders gotten from their clients that might be interior or exterior. Stocks that are released are called Goods Outward.

Most IMS are created to immediately uploaded orders right into the systems for handling. Once orders are published, the system identifies out-of-stock products as well as produces a Pick List (PL) for the staying ones revealing the places where they are to be selected by the driver.

Similar to the innovation made use of for put-away, light-based innovation might be made use of to assist the driver to the specific area to choose the products. Based on the last Pick List, a billing or Goods Issue Report (GIR) is published.

The supplies hence selected are relocated to the packing location based on a filling strategy. A Daily Loading Plan (DLP) is prepared by the procedures manager thinking about the complete variety of orders to be sent off for the day as well as the top priority of each order. The called for vehicles or eighteen-wheeler need to be scheduled the transportation of these products as well as personnel designated to manage the packing features.

Documentation

Goods that are secured of the storage facility for shipment or send off need to be sustained by their correct paperwork. Invoice, packaging listing, delivering files when it comes to products for export, clearance from Road Transport authorities in specific situations, and so on are simply a few of these. These need to be collected as well as maintained all set for the vehicle driver of the vehicle carrying the products.

Cross Docking

Also called Dock- to-Dock, cross-docking is a really efficient approach of carrying products in between places without needing to take advantage of intermediate storage space. In this approach, rather than keeping the products, they are examined as well as promptly packed onto a setting of transportation for straight shipment to the client.

Cross- docking is executed from a storage facility marshalling or hosting location. This is the location where products are constructed momentarily throughout their invoice or send off. In some situations, it might likewise be done from the port/airport/railway backyard as well as sent out straight to the client. Cross- docking is typically done when products are moved from the vendor to the representative. It conserves time, initiative, as well as cash.

Stock Counts

Warehouse supply counts or stock-takes aid to verify the precision of supplies kept in the storage facility. In various other words, it inspects whether the supplies based on physical matter suit with the supply of products according to the system, at a provided moment.

Generally, a yearly supply matter is a lawful need for a signed up company. It might likewise be performed quarterly or half-yearly. Periodic supply counts aid to identify mistakes or problems such as pilferage etc. Discrepancies that are located throughout a supply matter are later dealt with or crossed out after authorization by the certified supervisor.

Pest Control

Pests create supply losses totaling up to numerous billion United States bucks annually. All storehouses need to be decontaminated at routine periods to stop problems brought on by vermin, rats, or various other bugs. The problems brought on by these animals can lead to significant losses, both to the supplies in addition to the storage facility framework.

For instance, rats might nibble right into the circuitry of equipment, or plastic as well as wood components, triggering fires or various other significant mishaps. Fumigation, catches, poisonous substance lures, and so on are some techniques of parasite control.

Other Value- included Services

Warehouses frequently offer value-added solutions to their clients to preserve them in addition to draw in brand-new clients. Some of the value-added solutions consist of packaging, labelling, paperwork, as well as various other such solutions.

Warehouse Security

Goods that are kept inside a storage facility as well as the storage facility framework might deserve millions as well as need protection from damages, pilferage, burglary, arson, and so on Warehouses have a commitment to guard the products that have actually been left in their safekeeping by their clients.

CCTV video cameras, activity sensing units, alarm systems, as well as efficient patrolling around the storage facility perimeter are necessary for the safekeeping of the building as well as products. A huge storage facility might have a safety and security supervisor to take care of such issues as well as to communicate as well as keep a great relationship with the regional police, station house, as well as various other regional authorities.

Insurance

Insurance cover is typically taken by the storage facility monitoring for the kept products in addition to the storage facility framework as well as all various other devices. There are different kinds of insurance coverage for storehouses. These consist of partial in addition to extensive insurance coverage to cover cases like fires, floodings, as well as various other kinds of losses.

However, it will certainly need to be developed that the loss was created in spite of the storage facility having actually taken all feasible actions to respond to these. The clients might likewise take insurance coverage on the products possessed by them.

Machinery as well as Equipment Used in Warehouses

Machines as well as devices are made use of in storehouses as well as lawns for the risk-free as well as effective handling of products as well as products wholesale or as different smaller sized devices. These are called Material Handling Equipment (MHE). They aid to lots as well as discharge products (products outside— products internal), action hefty freight in between places, and so on

Examples of product handling devices are forklifts, cranes, pallets, durable sheets for covering products, and so on. A storage facility supervisor needs to make certain that all MHE are serviced according to their recommended solution periods as well as upkeep agreements remain in area.

Modern storehouses are created to make certain the optimum performance of their procedures. Such storehouses have the most recent devices as well as software program such as an Inventory Management System (IMS) to maximize their inventory-related procedures. The IMS is frequently incorporated with an Enterprise Resource Planning (ERP) system to unite the various features as well as divisions, thus boosting the company‘s system ability.

However, certified as well as effective personnel are the foundation of any type of effective logistics procedure. How much ever before automation as well as digitalization that might have can be found in current times, effective personnel to manage these is of terrific significance.

In a sector that is determined by intense competitors, storehouses that take advantage of the most recent patterns in innovation as well as which are run by effective supervisors as well as personnel are constantly the front-runners.

Please note that what we have actually pointed out in this post are a few of the highlights as well as performances of a modern-day storage facility.

There might be storehouses that are geared up with various other newest as well as personalized devices. Warehouses might likewise provide centers as well as solutions to their clients, aside from what is pointed out right here.