Several doubtful practices are employed by bunker gasoline suppliers throughout a typical bunker stem operation. These malpractices are extra prevalent in Asian ports than in these of North America or Europe. Having stated that irrespective of which a part of the world the vessel is mounted to stem bunkers, the significance of precisely measuring the barge gasoline tanks earlier than and after supply is a vital part in any bunker stem operation. It is due to this fact essential that the vessel’s bunker operation staff methodically take the barge tank measurements, making use of the proper trim/record earlier than and after bunkering, recording the precise temperature of the bunker gasoline earlier than/after supply and so on. Proper temperature measurement alone can save 1000’s of {dollars}!

Disputes can come up both by harmless mistake or deliberate brief provide by the barge; like introducing air to froth up the gasoline (cappuccino impact) or giving incorrect temperatures and so forth. Also when bunker is being transferred from a refinery to a storage tank and to the barge after which delivered to the vessel, there may be a number of scope for errors and deliberate manipulations that can lead to a distinction (typically fairly important) between the amount claimed to have been equipped and the amount obtained by the ship. If this is because of an harmless mistake then most likely with fullest co-operation of the barge firm/ gasoline suppliers and full disclosure of inventory motion data may point out the “missing” bunker.

However, usually this isn’t the case and expertise tells us that when disputes do come up over amount transferred, any ‘post-delivery’ investigation on amount shortages are sometimes inconclusive particularly if the shipboard personnel concerned in bunkering operation have uncared for the fundamental rules of safeguarding it’s house owners/charterers’ rights in means of accumulating and preserving proof. Protests, authorized charges, and so on. all add on to prices with normally neither social gathering really concluding with certainty what transpired on board. A hit of any bunker dispute declare will largely rely on the detailed contemporaneous written proof by the shipboard personnel on the time the availability is made.

Considering the current bunker gasoline costs we deem “bunker stem survey” completely essential, in an effort to be sure that the portions as talked about on the Bunker Delivery Note (BDN) are true and proper. However, there are various ship operators who go away the above process to the Chief Engineer to save lots of on survey price with the vessel usually ending up with an incorrect equipped amount and a industrial lack of 1000’s of {dollars} for the operators.

It is essential to notice that when a surveyor is appointed by the charterers / house owners to supervise the stemming operation, the Master/Chief Engineer remains to be answerable for guaranteeing correct steps have been taken to forestall such malpractices and that the surveyor ought to be aiding and dealing beneath the Chief Engineer’s supervision and never the opposite means round.

‘Unfortunately ‘stealing bunker fuel’ for revenue attributable to growing gasoline costs is right here to remain for a very long time to return’.

Loss prevention throughout bunker stemming largely is determined by the hands-on strategy and sensible expertise of bunker surveyors and AVA Marine’s unique division “Bunker Detective” is ready to supply these ‘Bunker Stem Surveys’ to ship house owners and charterers globally.

The steerage talked about on this article shouldn’t be construed as exhaustive and is aimed primarily for vessel operators and ship house owners to teach their shipboard personnel for higher detection and prevention of those malpractices for occurring within the first place.

What the ship house owners and operators have to know:

The ship proprietor and the charterer each have the duty for the availability of bunkers – in a time constitution the charterers will present bunkers whereas in a voyage constitution the house owners will usually provide bunkers. Therefore it will be important for each the house owners and the charterers to concentrate on the tips of the commerce throughout bunker stem operations.

1. Understanding the Fuel Density & Weight Relationship

Marine gasoline is at all times bought by weight (mass) and delivered by quantity. Hence for that reason bunker receipts should at all times be signed “For Volume Only” and including the phrases “weight to be determined after testing of the representative sample”. Never signal for weight if unsure in regards to the density.

What many bunker surveyors don’t notice is that the density given within the provider’s bunker supply be aware (BDN) will not be true and thus the burden decided by calculation ought to be thought of because the ‘preliminary’ weight of the gasoline transferred to the vessel. The precise weight is just decided after the density is verified by an impartial gasoline testing authority after which factored into the ultimate recalculation of the particular weight of the gasoline delivered onboard. That is why we at all times stress the significance of precisely acquiring bunker samples each onboard the vessel and the barge.

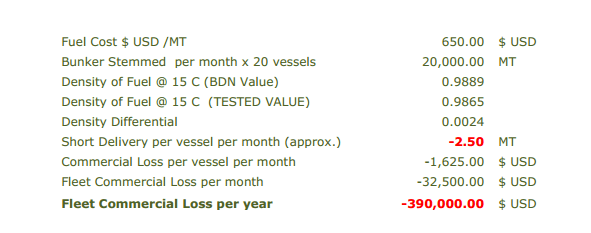

Once the samples are dispatch to the vessel’s chosen impartial gasoline testing laboratory we request the copy of the Fuel Test Reports in order that revised bunker survey report may be despatched to the consumer. Below is typical situation of how density can have an effect on the burden of gasoline transferred on board.

A ship proprietor/charterer has a fleet of 20 vessels bunkering a median of 1000 MT every month.

Now think about a charterer working a fleet of fifty, 70 or 100 vessels – the industrial loss could be worth in tens of millions of {dollars} yearly!

Key Notes:

- If the density of gasoline can’t be verified onboard or independently verified on the time of bunkering, the BDN ought to be signed just for ‘volume’ and never for weight

- Remember each time doubtful or have issues at all times problem a letter of protest

2. Understanding the Fuel Temperature & Volume Relationship

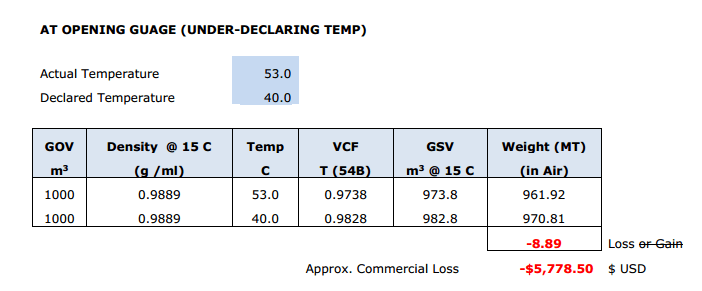

Petroleum merchandise have a excessive fee of thermal enlargement which should be taken into consideration when a number of thousand tons are transferred or bought. The barge will usually attempt to under-declare the temperature in the course of the opening gauge and over-declare in the course of the closing.

This malpractice is sort of frequent in everyday bunkering and due to this fact we at all times ask the ship officers accountable for bunkering operations to be additional vigilant and examine the temperatures of all bunker tanks in the course of the opening gauge and thereafter periodically examine and report the temperature of the gasoline as it’s pumped onboard. The temperatures ought to be checked each on the barge and the ship’s manifold. If temperature gauges are supplied it might be prudent to take pictures the place permissible.

The barge will usually attempt to under-declare the temperature in the course of the opening gauge and over-declare in the course of the closing. Always confirm temperatures of all bunker tanks in the course of the opening gauge and thereafter periodically examine and report the temperature of the gasoline as it’s pumped onboard. The temperatures ought to be checked each on the barge and the ship’s manifold and common of all of the readings taken throughout ultimate calculations. If temperature gauges are supplied it might be prudent to take pictures the place permissible.

Also be aware that the present circulation measurement methods can have a separate temperature and stress gauges the place these might simply be tempered with or gauges not being correct like non-aqueous liquid crammed gauges with glycerine and silicone oils usually seen with damaged sight glass. The entire objective of a liquid crammed gauge is for the liquid to soak up vibrations, thus offering a dampening impact to allow correct readings and in addition to scale back put on and tear by lubricating all shifting elements – in different phrases this impacts the integrity and reliability of the gauge readings over time.

There have been instances the place the glass within the mercury cup case thermometer is gently heated to create a bubble impact to forestall the proper registering of the temperature of the gasoline oil. This malpractice could possibly be illustrated by the next instance:

Within a big fleet the loss might run into tens of millions of {dollars} a yr!

Key Notes:

- Always examine and report the temperatures of the gasoline tanks earlier than and after and periodically throughout bunkering operation

- Carry personal infra-red laser temperature gun as part of your tools

- Remember each time doubtful or have issues at all times problem a letter of protest

3. The Cappuccino Bunkers: (additionally typically referred to as the Coca Cola Effect)

This basically could also be described as frothing/effervescent impact brought on by compressed air blown by the supply hose. The aerated bunkers when sounded will give the impression that the gasoline is delivered as ordered. In truth after someday when the entrapped air in suspension settles out of the gasoline oil the oil degree drops and a brief fall is found. In massive bunker deliveries this could possibly be appreciable with large monetary implications. Know extra about Cappuccino Bunkers right here.

We have usually been requested why the circulation meter can not detect the air being launched within the system and compensate accordingly. Well, most circulation meters in use right now are of both the fallacious sort or the fallacious dimension. In different phrases should not technologically superior. All the usual circulation meters will solely measure the amount of throughput and never the precise mass of gasoline being delivered. As a end result when is air launched into the system, which is basically ‘small air bubbles’ – the circulation meter will register it as quantity.

However, there are circulation meters out available in the market that are able to measuring the true amount (mass) of the gasoline delivered. One such meter is the ‘Coriolis Mass Meter’ – it has been in existence for fairly a while now and solely getting higher. Coriolis meters take direct mass circulation measurements utilizing the Coriolis Effect (a deflection of shifting objects when they’re considered in a rotating reference body –we received’t be discussing this impact as that is past the scope of this text). Coriolis meters are much less delicate to stress, temperature, viscosity, and density modifications, permitting them to measure liquids, slurries and gases precisely with out the necessity for compensation. These meters having no shifting elements require little upkeep nonetheless, the preliminary price and line modifications is normally a deterrent for a lot of ship operators for not putting in it.

Precautions towards Cappuccino Bunkers:

Before Fuel Transfer

At the time of opening gauge gasoline oil ought to be noticed from ullage hatches for any foam on the floor of the bunkers. Foam might also be detected on the ullage tape. If there isn’t a foam then the oil degree on the tape ought to seem distinct with no entrained bubbles. If by commentary of the tape and the floor of the gasoline you think entrained air then get hold of a pattern of the gasoline by reducing a weighted bottle into the tank. Pour the pattern right into a clear glass jar and observe rigorously for indicators of froth or bubbles.

If these observations present entrained air the Chief Engineer shouldn’t permit the bunkering to start out and notify the house owners / charterers instantly. The barge Master ought to be issued with a letter of protest and a duplicate despatched to the ship’s agent. If the barge Master decides to disconnect from the ship and go to a different location then the agent ought to instantly inform the port authority and attempt to set up the place

the barge has gone. All related instances and information ought to be recorded within the deck log e-book.

During Fuel Transfer

If the Chief Engineer has not noticed any entrained air in the course of the preliminary barge survey it’s nonetheless potential that air may be launched to the barge tanks or the supply line in the course of the pumping interval for instance by introducing air into the system by crack opening the suction valve of an empty bunker tank whereas pumping from different tanks. Hence it will be important for the Chief Engineers to proceed gauging the ship’s receiving tanks whereas the bunkering is in progress as air bubbles could be readily seen on the sounding tape.The Singapore Bunkering Procedure SS 600 prohibits using compressed air from bottles or compressors in the course of the pumping interval or throughout stripping and line clearing. It ought to be confirmed with the barge Master that he’ll comply with this process (Reference SS600 paragraphs 1.12.10/11/12/13).

Stripping of barge tanks can even introduce air and stripping ought to solely be carried out on the finish of the supply for a brief time frame. The barge Master should agree to tell the Chief Engineer when he intends to start out stripping and when it has been accomplished.

Ship’s crew and surveyor must be alert throughout bunkering and examine for the next indicators:

- Bunker hose jerking or whipping round.

- Gurgling sound when standing in neighborhood of bunker manifold.

- Fluctuations of stress indication on manifold stress gauge.

- Unusual noises from the bunker barge

After Fuel Transfer

It can be potential to introduce air into the supply line throughout blowing by at excessive stress. Therefore it’s crucial that the barge informs the ship earlier than and after blowing by is accomplished in order that the ship crew may be additional vigilant throughout this era.

The ship’s bunker manifold valve ought to be checked shut earlier than gauging of the vessel’s tanks.

Key Notes: (IDENTIFYING CAPPUCCINO BUNKERS)

- Signs of froth/foam on the floor of the gasoline within the barge tanks throughout opening gauge

- Excessive bubbles on the sounding tape previous to, throughout and after bunkering

- Bunker hose jerking or whipping round

- Slow supply charges then what has been agreed

- Gurgling sound in neighborhood of bunker manifold

- Fluctuations of stress on manifold stress gauge.

- Unusual noises from the bunker barge

Note that hose jerking or proof of sporadic bubbles superficial in nature after line blowing or stripping of tanks is pretty frequent and shouldn’t be construed as proof of malpractices.

4. Fuel Delivered with High Water Content

Traces of water in bunker gasoline are usually very low about 0.1-0.2% by quantity. ISO 8217:2010 Fuel Standards for ‘Marine Residual Fuels’ provides the utmost allowable water content material to be 0.5 % v/v.

Water can originate from variety of sources like heating coil injury inflicting leakages and tank condensation; nonetheless deliberate injection can’t be dominated out. In case massive amount is discovered then a letter of protest ought to be issued instantly. However, the precise amount of water can solely be decided after the settlement part the place the water would have settled down on the backside of the bunker tank.

Key Notes:

- High water content material causes different points like elimination prices to ashore if the OWS (Oily Water Separator) onboard will not be capable of filter it out and in addition reduces the gasoline’s particular vitality

- Fuel samples supplied by the barge could not have any traces of water because the samples could have been taken previous to bunkering and mixing of water. Always make sure that the gasoline samples are collected throughout bunkering and never earlier than or after. For these causes by no means signal labels prematurely or signal for samples of unknown origin. Samples ought to solely be signed for these really witnessed.

- Use of water-finding paste on the sounding tape is sweet for distillate fuels solely and doesn’t work with residual fuels. Even incorrect sort of ‘water-detecting’ paste could possibly be used.

- On-site testing ought to be achieved for water-in-oil check. It could also be not viable for the ship operators to spend money on excessive finish tools for such functions however at the least the vessel ought to be capable to check a bunker consultant gasoline pattern for water, check for density and compatibility

- Remember each time doubtful or have issues at all times problem a letter of protest

05. Inter-tank Transfers (gravitating of gasoline)

During opening gauge the gasoline could possibly be transferred from excessive degree to a low degree (or empty / slack tank) by gravity. For instance a barge could have 4 tanks 1P/1S, 2P/2S, 3P/3S and 4P/4S. The opening gauge begins from say aft tanks 4P/4S. While the gauging is underway, the tank degree of 4P/4S could possibly be simply dropped beneath gravity to a slack or empty tank ahead say 1P/1S. Thus basically the identical gasoline amount is measured twice. This technique remains to be in use and if not detected the barge can declare that full amount was delivered to the vessel however the vessel can have a considerable shortfall. Once the bunkering has commenced it’s too late to do something and will probably be just about not possible to hint the ‘missing’ gasoline. A radical investigation will likely be wanted to find out the precise inventory management amount and full disclosure from the provider which might take many months/years of authorized motion and nonetheless the matter will not be resolved. Read extra on gravitating of gasoline right here.

It is crucial that the attending surveyor or vessel’s consultant re-gauges the tanks within the following sequence:

If the preliminary gauging was ahead to aft, then after gauging the final aft tank; the surveyor or vessel’s consultant ought to re-gauge all tanks from aft to ahead. The readings ought to be precisely the identical.

As an extra precaution, on the graduation of bunker switch, the surveyor or vessel’s consultant ought to re-gauge the primary tank(s) used to switch oil to the vessel. The studying ought to match that taken in the course of the preliminary gauging.

Key Notes:

- The solely efficient means of coping with this doubtful observe is re-sounding the tanks as above earlier than bunkering commences

- Remember each time doubtful or have issues at all times problem a letter of protest

6. Flow meter/Pipe work Tampering

Bunker barges fitted with a circulation meter ought to be checked for correct functioning by sighting a sound calibration certificates and guaranteeing the seal is unbroken.

There might also be unauthorised piping (by-pass strains) fitted to the circulation meter working into the pump suction facet and thus this unauthorised contraption will register the throughput of gasoline twice by the circulation meter.

Key Notes:

- Verify circulation meter seal is unbroken

- Verify validity of the calibration certificates and that it’s for a similar sort circulation meter

- Look out for any suspicious by-pass strains working after the circulation meter

- Consult the barge piping diagram if doubtful

- Remember each time doubtful or have issues at all times problem a letter of protest

7. Quantity measurements by circulation meter solely

The barge could declare that the soundings and ullage ports have been sealed by customs or seized or another causes and due to this fact drive the vessel to go by the volumetric circulation meter solely.

Remember that this can be simply the primary signal of an unscrupulous barge Master as such we cautious of different tips of commerce.

Key Notes:

- Never agree and go by the circulation meter solely gasoline supply

- Remember each time doubtful or have issues at all times problem a letter of protest

8. Pumping / Mixing Slops into Bunkers

Though we seldom come throughout this now due to tighter sampling procedures in place however introducing slops and thus contaminants into the gasoline supply will cut back the precise gasoline quantity and in addition can create engine issues down the road. Unfortunately this can’t be detected till the consultant gasoline samples have been examined by an impartial gasoline testing facility.

A typical situation the place this malpractice could be carried out is after an argument over brief provide; the barge would pump in sludge / water to make up for the brief provide. As the pattern assortment would have been accomplished; it’s due to this fact crucial that if allowed a second pumping re-sampling is completed each on the barge and the vessel.

Key Notes:

- Always witness and acquire samples by steady drip technique i.e. the pattern to be drawn repeatedly all through the bunkering supply interval

- It ought to be a observe onboard to isolate the gasoline delivered to separate tanks and to not be consumed till such time the gasoline testing report provides a clear invoice of well being

- In case of second pumping re-sampling ought to be carried out each on the vessel and the barge to make sure no contaminants like sludge/water is been delivered to the vessel

- Fuel contamination amongst different issues can create issues with the gasoline injection system and exhaust valves with pricey repairs

- Remember each time doubtful or have issues at all times problem a letter of protest

9. Questionable Tank Calibration Tables

Verify that the sounding / ullage tables are accredited by the Class (Class Certified – with endorsement). Having a couple of set of sounding e-book will not be unusual and having the tables modified to the provider’s benefit is at all times a risk. Inserted pages, corrections, totally different print/paper sort are all indications of tampering. Sometimes the barge could have a brand new calibration desk (with the outdated one being out of date). This could possibly be following modification of the tanks inside construction throughout a dry dock restore or just because the unique calibration tables would have been incorrect. Always discover out the explanation for brand new calibration desk and ensuring it’s Class Certified.

The identical could possibly be stated for the record / trim correction tables which could possibly be simply modified once more to the provider’s benefit.

Key Notes:

- Look for Class Approved calibration tables with endorsement

- Remember each time doubtful or have issues at all times problem a letter of protest

10. Tampering with Gauging Equipment

Always confirm the situation of sounding tape. Sounding tapes could possibly be tampered with in some ways:

- Deliberate altering of sounding tapes and utilizing fallacious dimension of bobs

- Sounding bobs from tapes which have been converted

- Cutting the tape and re-joining leading to non-linear tape

Key Notes:

- Check for calibration certificates for the gauging tools in use

- Use a ruler to determine the exact sounding/ullage when beneath the 20 cm mark

- Use personal sounding / ullage tapes

- Pay specific consideration to ‘millimeter’ soundings particularly when the tanks are full and taking ullages as small errors can have a huge impact on the whole bunker amount.

- Remember each time doubtful or have issues at all times problem a letter of protest

11. Empty Tanks -Unpumpable Fuel (Zero Dip Volume Application)

In an occasion of a brief supply be cautious that vacant tanks will not be empty even with zero dip and that substantial pumpable could exist. Verify the tanks claimed to be empty – don’t take the provider’s phrase for it.

Zero dip quantity software precept – The bunker surveyor or the vessel consultant ought to notify the barge consultant that the zero dip quantity of the tank(s) shall be included within the bunker tanker calculations. The situation shall deemed to use when the closing gauge would point out no oil reduce whereas the visible inspection of the bunker tanker cargo tank point out free flowing oil on the aft of the tank. To keep away from zero dip quantity software, enough bunkers ought to be retained in cargo tanks such that it touches all 4 sides of the tank.

To apply zero dip correction – it’s assumed that the tank is rectangular the place the sounding will not be constrained by a sounding pipe – i.e. sounding ought to be taken in an “open sounding” place (from the hatch) the place the sounding tape bob is free to journey with the trim of the barge and never restricted by the sounding pipe. However, if the tape is used inside a sounding pipe this correction could be invalid.

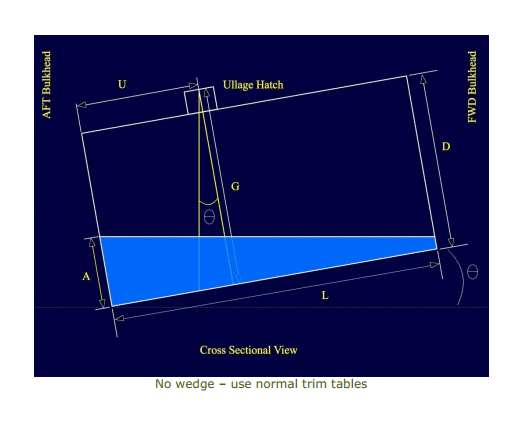

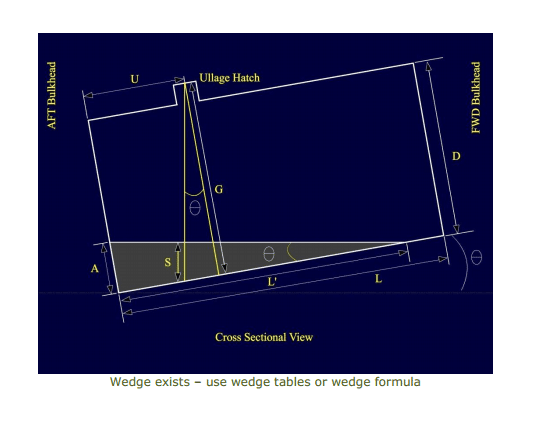

Liquid cargo ought to solely be trim and/or record corrected if the liquid is in touch with all bulkheads. When the liquid will not be in touch with all bulkheads, a wedge correction ought to be utilized.

*Cut – The oil degree on the tape or bob or the water degree marking on a tape or bob coated with water indicating paste. “Taking a cut” is taking a measurement of the oil or water degree.

Key Notes:

- Do not assume any tanks to be empty even when reaching stripping degree

- Check tank calibration tables to confirm the unpumpable

- Apply appropriate record / trim corrections throughout calculations

- Remember each time doubtful or have issues at all times problem a letter of protest

12. Inflated / Deflated Tank Volumes

Level of oil on the tape / bob ought to be clearly identifiable (identical color and viscosity as the remainder of the oil within the tank).

Soundings may be inflated throughout opening gauging by pouring diesel oil into the sounding pipe simply earlier than gauging.

Another technique of inflating the sounding is excessive stress compressed air being injected immediately into the sounding pipe, pressurizing the pipe and thus inflicting the extent of oil to rise giving a better studying with out even frothing or creating bubbles. This could be achieved en-route to the vessel simply earlier than supply.

The reverse is true – that’s the soundings may be deflated throughout closing gauging by pouring copious quantity of paint thinner into the sounding pipe simply earlier than gauging. The thinner washes off the oil degree marking on the sounding tape to point much less oil.

Key Notes:

- Always examine the extent of on the sounding tape and if doubtful re-gauge the tank

- Remember each time doubtful or have issues at all times problem a letter of protest

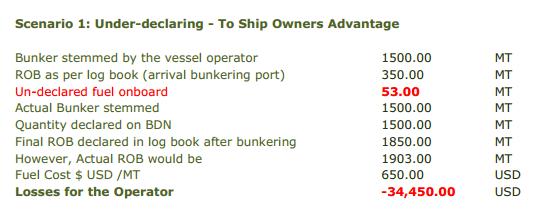

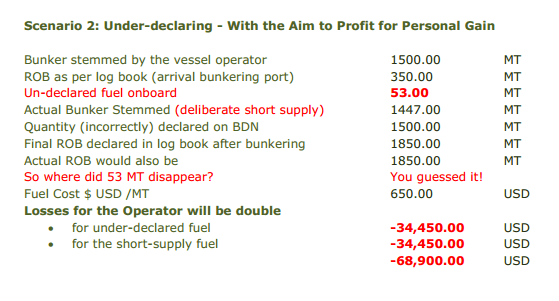

13. Under-Declaring precise ROB and Deliberate Short-Supplying of Fuel

Why it will be important for the ship operators to determine the precise gasoline amount onboard prior stemming bunkers?

The malpractices throughout bunkering operations which we see and listen to about although fairly prevalent with bunker suppliers; however on many events we now have come throughout conditions the place the receiving vessel will likely be as a lot as concerned because the provider in these doubtful practices. Often we now have discovered that the vessel would under-declare gasoline amount which is then both bought again to the barge provider or just stored hidden on the vessel till a possibility comes alongside to revenue from this.

For instance: An order for 1000 metric tons of FO is positioned on the subsequent bunkering port – the vessel has an extra of fifty metric tons (un-declared). Now when the availability barge comes alongside (by prior negotiations) the vessel would intentionally short-receive (or barge will intentionally short-supply) 50 tons.

In different phrases the precise equipped amount could be 950 tons however on the BDN it might be reported as 1000 tons and the operator will likely be invoiced based mostly on this BDN amount. The short-received (or brief delivered bunker) revenue will likely be shared between the provider and the vessel. In the tip it’s the operator who’s affected – struggling the loss twice (50 tons + 50 tons).

Contributing components for the loss:

- Too a lot reliance on the vessel’s workers

- No bunker stem audits are performed which entails elaborate detective work carried out by impartial third social gathering surveying companies

- Ignoring non-nominating (non-receiving) tanks to be included within the general tank measurements throughout stem operations

- Most transport firms will interact the providers of an impartial surveyor to guard their curiosity in case of a giant discrepancy within the ultimate figures between the barge and the vessel; nonetheless, what number of firms really give clear directions to the attending surveyor to measure all non-nominated tanks (non-receiving tanks)? Or what number of surveying companies really perform the measurements diligently? Failing to take action leaves the operator weak as defined above.

This is additional illustrated as follows:

The extra 53 MT of gasoline oil will likely be in favor of the house owners with a loss to the charterers

Key Notes:

- Carry out common ‘bunker stem audits’ – in a big fleet that is an indispensible loss management device

- Measure all non-nominated tanks previous to stemming operations and once more after bunkering is accomplished

- Always interact the providers of a good bunker stem surveying agency throughout stem operations.

About Bunker Detective:

Bunker Detective is an unique division of AVA Marine Group Inc. AVA Marine is knowledgeable marine surveying and consultancy agency – based and led by its principal marine surveyor Kaivan H. Chinoy. The Company gives a complete vary of specialist marine surveying, marine loss management & consultancy providers primarily in Western Canada and the West Coast of the United States. To study extra about their marine surveying capabilities, go to the web site at ava-marine.com / bunkerdetective.com

Special due to Kaivan H. Chinoy From Bunker Detective for giving us permission to reproduced this text.

Disclaimer: This article relies on the writer’s personal analysis, information and expertise in the subject material and references used from numerous P&I LP bulletins and will solely be used for reference reasonably than being taken as a authorized

recommendation for any specific case or used for every other objective.

Over to you..

Do you’ve extra info or expertise to share on the bunkering malpractices? Let’s know within the feedback beneath.