Guide To Types of Warehouses for Shipping

Importance Of Warehouses

Goods in the procedure of delivery require risk-free and also protected storage space to safeguard them from the components of nature, damages and also devastation as a result of negligent handling, pilferage, and so on

In service, items call for storage space as they wait on the consumer. Warehouses are structures and also associated facilities that are made use of for the storage space of items.

Warehouses have the centers for obtaining items, piling or saving them securely, and also choosing these items when it is time to deliver them to a consumer or a brand-new area.

These tasks need to be executed while making sure the security and also safety and security of workers managing the items at the storehouse, along with the items.

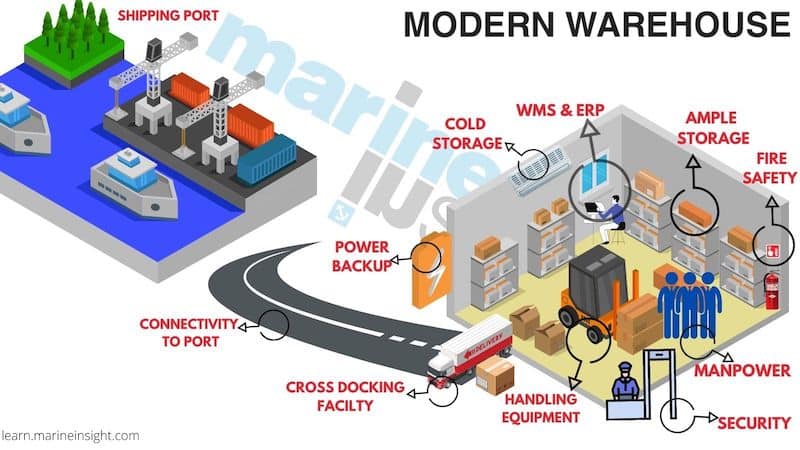

Modern stockrooms have actually come a lengthy method from conventional items drops or items lawns.

An items shed is a structure with no storage space facilities that is made use of for the piling of items. Usually, such structures have no correct security or safety and security functions. An items lawn is an open yet generally encased substance where items are maintained.

Most modern-day stockrooms are crafting wonders. They have the most up to date storage space and also managing tools and also stock monitoring innovations.

While enhancing storage area, these newest functions make sure precise stock-keeping and also selecting of items.

When the globe is a lot more aware regarding the top quality of items, food security, and so on safety and security and also health of the kept items are provided utmost significance in such stockrooms.

Important Features of Modern Warehouse

Let us have a look at several of the essential functions of a modern-day storehouse.

Availability of Appropriate Storage

Most modern-day stockrooms have an ambient, cool, and also icy storage space centers to satisfy the various demands of the marketplace. It prevails to have a consumer with the demand for these 3 kinds of warehousing under one roofing system.

Accessibility to Markets and also Ports

Most effective stockrooms have closeness to ports. It makes transport of items simple— for imports along with exports.

Safety and also Security

For the security and also safety and security of workers along with the items kept within, stockrooms nowadays, have trained safety and security team, CCTV, movement sensing units, temperature level sensing units in storage space locations, fire-fighting tools, and so on They satisfy all the security and also safety and security criteria suggested by the appropriate authorities.

Efficient and also trained team

Well- educated and also reliable team aid run a stockroom efficiently with correct preparation and also implementation of procedures.

Latest storage space and also managing tools

Modern modern technology plays an essential duty in the success of any type of warehousing and also logistics procedure. Equipment, equipment, and also software program made use of ought to be updated regularly to satisfy the needs of the marketplace while making it simple for the customer to take care of.

Cross- docking centers

One essential attribute that the majority of consumers keep an eye out for in stockrooms is the center to cross-dock.

What is cross-docking?

When items are obtained and also selected quickly for send off and also distribution without saving them inside the storehouse, it is called cross-docking. This conserves time, storage area, and also price.

Warehouse Management System (WMS)

A Warehouse Management System (WMS) software program maximizes storage space and also the receipt-stacking-picking treatments. It is a system of enhanced stock monitoring.

Enterprise Resource Planning (ERP)

ERP software program incorporates stock monitoring, principal and also consumer connection monitoring, along with audit. This all-in-one software program incorporates the features of a stockroom and even the entire service.

Emergency back-up

Facilities for back-up in case of power failings, equipment and also tools failure, and also various other unanticipated disasters ought to remain in area.

Some modern-day stockrooms also have arrangements partnering with various other stockrooms to supply on a reciprocatory basis, storage space and also various other centers in case of a failure.

Large service residences might have stockrooms. Those without any storehouse centers have the alternative to head to public or personal stockrooms for their storage space requires.

A wide category based upon possession and also operating of stockrooms consists of public, personal, and also participating stockrooms.

Types of Warehouses

Public Warehouses

Public stockrooms are government-run yet readily available to both the general public and also economic sector companies. They may not be state-of-art or highly ahead, yet they satisfy of storage space of items at budget-friendly prices.

Most such public stockrooms lie in quickly obtainable locations that are close to markets along with ports or airport terminals.

Private Warehouses

Private stockrooms are run by personal companies. Some of them might be for the unique storage space of items of the possessing firm while others are readily available for the storage space of items to the general public.

Other than availability, being highly onward is their strength. These days most personal stockrooms have actually relocated from simply being storage space areas to logistics company.

Other than supplying storage area for the items of their consumers, they assist with preparation, application, and also implementation of the consumer‘s transport requirements, getting, choosing of items, and also acquisition demands. In various other words, it indicates all the incoming and also outgoing tasks of the consumer.

The terms ‘inbound and outbound’ extensively equate to buy from principals and also sales to consumers. Modern logistics firms generally satisfy all the demands of their consumers.

They might use storehouse monitoring systems (WMS) for precise stock monitoring and also business source preparation (ERP) for automation of all logistics-related tasks consisting of audit and also consumer connection monitoring (CRM). In particular instances, the ERP consists of WMS.

Cooperative Warehouses

Farmers, orchard and also winery proprietors, aqua-culturists, and so on generally develop cooperatives. These cooperatives might have stockrooms that supply the ideal storage area to their participants at subsidized prices.

Depending on the accessibility of area, participating stockrooms might additionally weep to outdoors events at a somewhat greater price.

An additional classification of stockrooms based upon energies given would certainly consist of adhered stockrooms, debt consolidation stockrooms, clever stockrooms, and so on

Bonded or Duty-Free Warehouses

Bonded stockrooms are customs-approved stockrooms that enable companies to keep their imported items prior to settlement of personalizeds obligations and also tax obligations.

Good can be kept in adhered stockrooms for an extensive duration till it needs to be taken outdoors offer for sale or usage after settlement of personalizeds obligations and also tax obligations.

The items that are kept in adhered stockrooms are identified as‘duty-free’ Once personalizeds obligations and also tax obligations are paid on the items that are secured, they are called ‘duty-paid’ items.

Storing items in an adhered storehouse gets rid of the requirement for prompt settlement of personalizeds obligations and also tax obligations upon obtaining the items.

It aids the functioning resources of a company as items are gotten rid of straight to the adhered storehouse without settlement of personalizeds task and also tax obligations.

This is advantageous to companies that import high-value items with a high price of personalizeds task.

Customs task is paid just when items are gotten rid of. Goods kept in adhered stockrooms can be reexported quickly. It additionally helps with top quality checks, arranging, product packaging, or handling of such items while in the adhered storage space.

Consolidation Warehouses

When a number of freight sets of little quantities from consumers, implied for the very same location are integrated and also delivered, it is called debt consolidation. Such items are accumulated, set apart, and also sent out by sea products, generally as complete container lots (FCL).

Consolidations aid when the quantity of freight to be delivered is little. Consolidators gather freight from the various consumers, combine these amounts from their debt consolidation storehouse to complete or near-full container lots for delivery. This aids to lower the products price. This is additionally called groupage freight.

Smart Warehouses

Smart stockrooms make use of the most up to date in modern technology for obtaining, saving, and also selecting of items. Smart stockrooms might additionally take advantage of drones or robotics for choosing, product packaging, and also piling items.

Enterprise source preparation (ERP) and also storehouse monitoring system (WMS) aids to make sure minimal human treatment in issues associating with fund, consumer connections and also the precision of supplies.

Such stockrooms are located extremely beneficial for the storage space of high-value digital components, pharmaceutical medicines, and so on

Warehouse Management System (WMS)

Warehouse Management System (WMS) documents the invoice, storage space area, choosing, and also send off of items from the storehouse.

It maximizes storage area by recommending the storage space area based upon FIFO, FEFO, or LIFO guidelines of choosing items. WMS gives real-time information to the customer.

First-In First-Out (FIFO)

First-In First-Out (FIFO) is the concept of choosing items based upon the invoice of items. Those items which were obtained initially are the ones to be selected for send off.

First-Expiry First-Out is (FEFO)

In First-Expiry First-Out (FEFO), the supply with the earliest expiration day (or Best-Before Date) will certainly be selected initially. Both FIFO and also FEFO aid in preserving supply quality at the very same time preventing aged supplies being in the storehouse.

Last-In First-Out (LIFO)

Last-In First-Out (LIFO) calls for the last product obtained to be selected initially for send off. An order from a favored consumer is an instance.

These choosing guidelines are based upon consumer demands. WMS aids with regular stock counts that are called for to make sure that supplies are kept precisely.

Enterprise Resource Planning (ERP)

Enterprise Resource Planning (ERP) consists of stock monitoring, principal and also consumer connection monitoring, and also audit. Data from WMS is made use of in ERP to produce precise service projections.

ERP is made use of in order and also accounting. It, for that reason, incorporates all these features and also the company does not need to purchase several software program to manage them.

Temperature- regulated Warehouses

As customer requires rise, they are additionally a lot more familiar with the requirement to obtain risk-free, tidy, and also sanitary items for the cash they invest, specifically when it pertains to food things, drugs, and so on Storage of items under the right temperature level in sanitary problems expands its service life.

Warehousing modern technology has actually equaled this need by having temperature-controlled stockrooms to satisfy the various demands of storage space of various kinds of things.

Depending on the kind of items kept, stockrooms can extensively be identified as ambient, cool, or iced up.

Ambient Warehousing

Also called completely dry warehousing or warehousing at room-temperature, items are kept in a completely dry, tidy, and also well-ventilated storage space location at temperature levels in between 14 ° C and also 24 ° C( 57.2 ° F and also 75.2 ° F).

Certain kinds of food things, veggies, fruits, container food things, electronic devices, and so on call for storage space at ambient temperature levels. The temperature level might differ somewhat according to the kind of product being kept.

Chill Warehousing

Chill stockrooms are made use of for the storage space of particular kinds of veggies, fruits, milk fruit and vegetables, meat, fish and shellfish, and so on Temperatures in between 7 ° C and also 14 ° C( 44.6 ° F and also 57.2 ° F) are kept in such stockrooms.

Frozen Warehousing

Frozen food, meat, fish and shellfish, and also some kinds of pharmaceutical medicines call for storage space under icy problems. Frozen food generally requires to be kept at a continuous temperature level of -18 ° C (-0.4 ° F) or much less. When the temperature level climbs over this, it influences the top quality of such things causing perishing.

Types of Warehouse Racking

Pallets are the level wood or plastic frameworks on which boxes or items are maintained in a stockroom. Pallets generally been available in a basic dimension of 48 inches X 40 inches though pallets of various other dimensions are additionally readily available out there.

Racking is the multi-level steel structure within a stockroom that holds a number of pallets.

An reliable racking system maximizes storehouse area making access of stock, item circulation (FIFO, FEFO, LIFO, and so on), and also availability of pallets much easier.

MHE’s (Material Handling Equipment) such as forklifts, automated pallet jacks, and so on ought to have the ability to place the pallets and also eliminate them from the shelfs quickly. Some of the various kinds of storehouse racking are as adheres to:

Selective Racking

Consisting of upright structures, straight beam of lights, dental braces, sustains, and also footplates, discerning racking is one of the most frequently located kind of racking in stockrooms.

Pallets can quickly be put-away and also gotten rid of from these kinds of shelfs as every pallet deals with the aisle ahead that can be made use of by forklifts or pallet jacks.

Selective shelfs are the most convenient to set up and also dismantle, utilizing screws. However, in discerning racking, storehouse area is not made use of to the optimum as a result of the area used up by a number of aisles.

Mobile Racks

Mobile shelfs are discerning shelfs yet with a wheeled-base. These shelfs can be relocated along the tracks that are installed on the storehouse flooring.

Ideal for saving items wholesale that do not call for to be relocated often, mobile shelfs supply the optimal area application within a stockroom.

Cantilever Racks

Cantilever shelfs include a number of upright solitary beam of lights, each with arms that expand external for bring the tons. It is specifically hassle-free for the storage space of lengthy and also unwieldy items such as steel pipelines, wood, steel trusses, and so on With a minimal variety of components, this kind of racking is extremely simple to establish.

There are a number of various other approaches of establishing shelfs inside a stockroom. Each approach is picked to match particular items that have particular storage space demands.

Modern stockrooms that satisfy the above consumer demands will certainly constantly remain in need. Setting up a stockroom calls for a great deal of preparation, maintaining development in mind.

Choosing the best kind of storehouse depends upon a firm‘s warehousing demands, spending plan, and also various other such service aspects.