How Perishable Food Items are Shipped?

The vibrant chain of need and also supply demands the activity of products in between centres of manufacturing and also need. Transportation of products whether they are of subject to spoiling or non-perishable nature calls for mindful preparation and also implementation.

Typically, non-perishable products are those that do not need refrigeration or unique storage space problems. They last for a very long time when maintained under regular storage space problems.

On the various other hand, subject to spoiling products such as food products degrade and also ruin otherwise saved in the recommended temperature-controlled problems. They have a brief life span that can just be prolonged by keeping under these recommended problems.

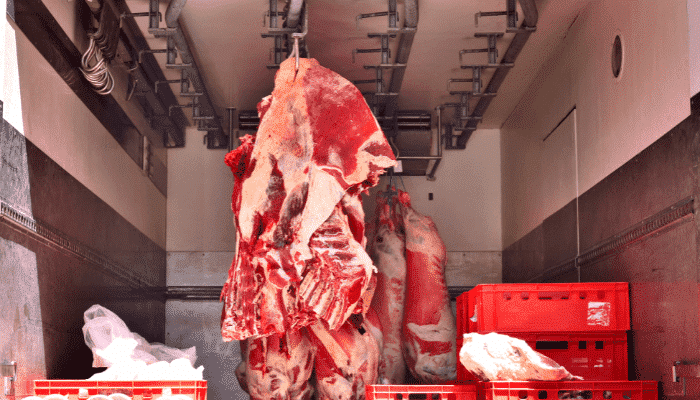

Food products such as bread, vegetables and fruits, milk items, meat and also fowl products, fish and shellfish, and also pharmaceutical medications are some instances of subject to spoiling products. They need unique storage space problems and also need to be moved in tidy, temperature-controlled containers. This is necessary to preserve the top quality of these products when they are relocated from their area of manufacturing to the marketplace and also completion consumer.

Almost all pharmaceutical medications require defense from straight sunshine and also dampness besides a great and also completely dry area of storage space. Similarly, some digital tools requires to be maintained in an atmosphere devoid of warmth, moisture, dirt, and also heats. Any discrepancy from these standards can lead to degeneration and also putridity of these items prior to it has actually reached their end-life.

Shipping of subject to spoiling products has actually constantly been a difficulty in logistics. Coordinating the activity of such freight in between the vendor‘s storage facility, carrier, customizeds and also wellness authorities, and also the consumer is challenging. Any mistakes can lead to significant losses to the stakeholders.

The simplest method to transfer subject to spoiling products is by the fastest setting of transportation— air. However, it has its restrictions. For instance, air freight transportation is pricey when compared to roadway, rail, or sea transportation and also therefore, it might not be financially practical to transfer a big quantity of freight by air.

Air freight delivered with firms without their very own freight X-ray makers need to wait with the obligatory 1 day cooling duration prior to being filled onboard the airplane. This is provided for safety factors.

In spite of these restrictions, transport of a number of kinds of extremely subject to spoiling freight is executed by airfreight.

Modern intermodal containers and also temperature-control tools have actually transformed the area of subject to spoiling freight transportation, specifically subject to spoiling food products. Temperature- regulated containers are frequently called reefers or chilled containers.

Refrigerated Containers

Transporting subject to spoiling freight by temperature-controlled intermodal freight containers, by sea, is one of the most favored approach when freight quantities and also the expense need to be thought about. Reefers are shielded delivery containers that are furnished with mobile temperature-control tools, temperature level surveillance and also information logging gadgets.

The temperature level within such containers might be evaluated the wanted degree to preserve the top quality of the freight. It might be evaluated reduced to extremely reduced temperature levels as when it comes to delivering icy meat or maybe at an ambient temperature level array. This would certainly depend upon the sort of freight being moved and also as recommended by the manufacturer or maker of the thing.

Refrigerated containers are made use of to transfer meat and also fish and shellfish at -30 ° C. The exact same container might be made use of to relocate ambient foods products at +24 ° C after the essential cleansing of the container.

Condensation

Condensation is a significant reason for degeneration and also putridity of subject to spoiling products along with their product packaging. Hence, all initiatives need to be required to make sure that condensation does not create throughout the loading and also dumping of the freight. This is when it is most at risk to condensation as there is a distinction in the temperature levels in between the storage facility and also the freight container.

It prevails to pre-cool a reefer container prior to filling subject to spoiling food products. It is after that turned off at the time of filling to avoid condensation. The container, after filling, need to have adequate area inside for the flow of air. Circulation of air inside a freight container makes certain that the subject to spoiling products inside remain fresh and also the container has an also, established temperature level.

In particular instances, completely dry containers are lined with shielded linings or vacuum cleaner panels to protect the temperature level of the filled products, though this could not be an extremely reliable approach for delivery subject to spoiling products over a cross country.

Certain various other essential aspects that need to be considered while sending out subject to spoiling freight by sea products are offered right here.

Timing

Timing is extremely vital while delivering subject to spoiling products. Waiting time at ports, awaiting customizeds clearance, transportation, and so on need to be factored in while computing the total preparation. What is preparation? It is the overall time required to relocate your freight in between 2 or even more areas. Lead time is a crucial consider preparation and also projecting.

Delays that are not factored right into the preparation can lead to supply expiration. This is where knowledgeable products forwarders can be found in. With their experience and also get in touches with, a lot of those hold-ups can be prevented.

Better paths can be selected for the activity of subject to spoiling products. Perishable products with their minimal life span need to be handed over and also grabbed precisely as intended. Arrangements for their temperature-controlled storage space must be made whenever a hold-up is anticipated or come across.

Quality Control and also Technology

The items being delivered have to be tidy and also bundles undamaged. Damaged or dripping bundles can cause contamination and also putridity. Besides, the container delivering such products have to be tidy, specifically the flooring, the within wall surfaces, and also the doors. It need to be devoid of tiny fungis and also various other microorganisms.

An extensive cleansing makes certain that the container does not have any type of smells that could get various other freight such as food products. The grooves of the door framework have to be tidy and also also to make sure that the door shuts and also secures the container completely.

The chilly chain of subject to spoiling freights have to be preserved throughout its trip. Various modern technologies such as Radio Frequency Identification (RFID), delivery monitoring, and so on can be made use of to track a consignment and also strategy appropriately. Temperature and also moisture sensing units and also screens assist to find failure of refrigeration tools enroute and also take prompt activities essential to guard the products.

Instructions and also Labeling

An vital aspect while sending out subject to spoiling freights is to give clear guidelines to those managing the products. Labels revealing handling and also storage space guidelines can assist in protecting the top quality and also problem of subject to spoiling freights. All vital stakeholders, specifically the consumer, need to be educated of the storage space and also transportation problems of the products.

Temperature determines might reveal the temperature level in Celsius along withFahrenheit It need to be discussed plainly whether the setup for the freight is Celsius orFahrenheit Several circumstances of products problems, as an outcome of complication in temperature level setups, are taken care of by insurance provider annually.

Among various other points, the carrier and also his provider need to talk about and also choose alternative plans to be made in case of a backup such as proper storage area, labor, and also tools to deal with the freight, and so on