An extremely basic description for the term transportation time is that– it is the moment or the variety of days considered a consignment to relocate from factor A to aim B. In delivery terms, this is described as transportation time or transportation days.

It is a crucial variable impacting organizations as well as any kind of various other procedures that acquire resources, components, or ended up products from vendors to be recycled, repackaged, or merely rearranged.

Generally described as resources, these products are delivered by vendors based upon order from the client, utilizing a practical as well as cost-effective setting of transportation as concurred in between both.

Why is transportation time crucial? Without obtaining resources, ended up products, or components from their vendors on schedule, any kind of service will certainly not have the ability to run. They will certainly not have the ability to satisfy their dedications to their clients.

Transit time is a crucial part of preparation. In service, preparation is the complete time required to understand an order put with a vendor.

It is a procedure of the complete time extracted from the minute an order is put with a vendor till the products are gotten at the buyer‘s stockroom.

Lean Business Models as well as Lead Time

Lean service designs operate a rigorous plan of waste removal as well as expense decrease. In the existing affordable service atmosphere, many companies operate lean service designs.

What are lean service designs? A lean service design is everything about lessening or removing waste within a company. This leads to enhanced client complete satisfaction as well as inevitably the productivity of the company.

Companies that adhere to the lean service design attain their goal by concentrating on renovation as well as optimization of their procedures as well as boosting the data base of their workers, consequently decreasing expenses.

Here, the preparations of the necessary products play a crucial function. Variations en route time impact the preparation. Fluctuating preparations can make order projecting challenging as well as impractical. Without obtaining the raw products at the correct time, firms can not satisfy their due dates.

When resources are gotten earlier than called for, it occupies storage room as well as likewise leads to unneeded stockholding for the firm.

Any hold-up in the invoice of resources would certainly impact the handling or manufacturing cycle. It may cause stock-outs that impact the prompt shipment of products to clients.

Just-In-Time (JIT) is a supply administration principle in which product as well as work for production are set up to show up just when called for as well as in the nick of time for the production procedure.

Lead Time as well as Transit Days

Typically, the break up of preparation is as complies with:

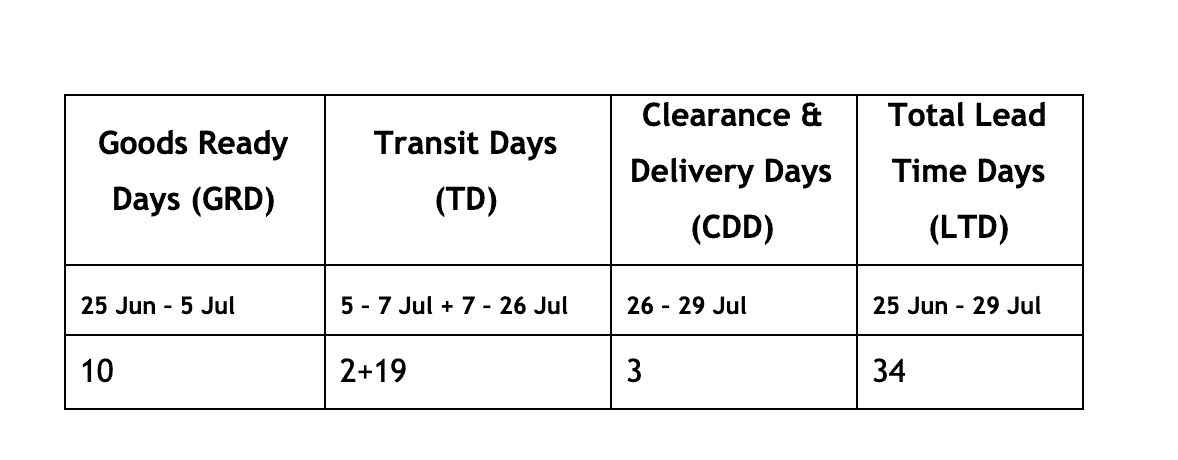

Total Lead Time = Goods prepared days + Transit days + Clearance as well as shipment days

Goods prepared days (GRD) is determined as the variety of days extracted from the moment of positioning an order with a vendor to the moment it is offered to the carrier for delivery.

The provider needs to have the products prepared as concurred with the purchaser as well as carrier. However, there might be hold-ups from the provider‘s end in preparing the products.

Production traffic jams, concerns with packaging as well as labelling, or insufficient export procedures as well as paperwork can create hold-ups.

Unexpected hold-ups from the provider‘s side might cause the freight missing its cruising. If it is a transhipment freight there is a likely opportunity of it missing out on all the succeeding cruisings from the various other ports.

Sometimes an order might contain various products from various resources that might need to be settled by the provider. Delay in combination can distress the shipment target date that has actually been concurred with the carrier.

Transit days (TD) is the variety of days extracted from when the products are gotten from the provider by the carrier, till it is released at the location port.

Transit days consist of the moment required to relocate from the provider‘s stockroom to the port of beginning, storage space days at the port if any kind of, the cruising time, as well as lastly, the moment required to release the freight at the location port, prepared for personalizeds clearance.

The variety of days it considers personalizeds clearance of the products as well as their shipment to the client‘s properties is the clearance as well as shipment days (CDD).

A straightforward instance of the break up of preparation by its various elements is provided listed below.

The Techstart firm in Chennai, India puts an order for 20 items of equipment with Yamaguchi & & Sons, Yokohama, Japan on 25June As concurred in between both firms, the variety of days to prepared this order is 10 days.

On 5 Jul, the carrier grabs these 20 systems as well as places them in a 20′ general practitioner container, as well as relocate to the port ofYokohama It is scheduled by vessel MV Marijan that sets out on the 7Jul The cruising time is 19 days from Yokohama to Chennai.

The vessel berths at Chennai port on 26 July as well as the products are released the very same day. Customs clearance takes one more 3 days as well as the container is moved to the stockroom of Techstart firm on 29 July.

The variety of days considered each part is as complies with:

Forecasting

Forecasting is the method of anticipating future needs by utilizing historical information. Different companies utilize various projecting designs to get to the need amounts.

The 2 primary sorts of projecting are measurable projecting as well as qualitative projecting. Quantitative projecting takes advantage of historic information to compute future needs while qualitative projecting takes advantage of judgment based upon previous or reoccuring occasions.

In qualitative projecting, mathematical information is not made use of for exercising future needs as well as it depends greatly on skilled as well as educated firm team or forecasters.

Lead time is vital in projecting as well as it is made use of to exercise the optimal order amounts. Forecasters as well as organizers need to take into consideration the various elements that might create hold-ups to their orders as well as get to the order numbers as necessary. Maintaining a maximum barrier supply to aid such emergency situations is one choice offered to forecasters as well as organizers.

Factors Affecting Transit Time

Several elements impact the transportation time of products.

Port terminals normally have their issues which subsequently might impact the transportation time of vessels. Inadequate managing devices at ports, devices failure, as well as work issues are simply a few of these.

Any of these issues can cause hold-ups to vessels, whether inbound or waiting to dive in. Delays impact the loading as well as discharging of freight.

Blank cruising of a freight vessel can distress the loading as well as discharging of freight at these ports. What is empty cruising? Blank or gap cruising is when a ship does not call at a set up port.

It can be a solitary port that is left out or greater than one, in the string. All the ports that are covered by the ship throughout its trip are called a string.

Blank cruising impacts all the freight waiting to obtain packed onboard the ship from the port or ports. Cargo that can not be packed will certainly need to take the following offered cruising. It leads to expanded transportation time.

It impacts discharging as well. When a ship misses a port, the freight that must have been unloaded at that port is released at the following port of phone call. Once once more, the transportation time is extended. For even more information on empty cruising please check out the write-up offered on the adhering to web link:

Transit time can be influenced by port blockages when the ship is unable to obtain a berthing port. Bad weather condition or modifications to the vessel’s cruising timetable can likewise impact transportation time.

Forecasters as well as organizers need to take into consideration all the numerous elements as well as strategy as necessary. These elements consist of climate condition at beginning as well as enroute, vacations as well as seasonal market closures, and so on

Customs clearance of freight after it is released at the location port should be prepared well. Discrepancies or mistakes in paperwork, failing to set up the needed work as well as transportation, and so on can needlessly expand the preparation.