What is Flexitank in Shipping?

Does your company call for moving big amounts of fluids or powders in drums or containers? The standard technique of moving these products is by steel or plastic drums, intermediate mass containers likewise called IBCs, or sacks constructed from plastic products.

Is the price of storage space drums or containers consuming right into your revenues? Is sourcing a huge storage tank container or a train storage tank vehicle a complicated job? If you responded to Yes to any one of these inquiries, a Flexitank is a response for you.

A flexitank is an option for those companies whose company includes mass fluids such as edible oils, particular kinds of commercial oils, fluid latex, glass of wines, juices, and so on, or perhaps powders. Almost any kind of fluid that is not unsafe can be carried making use of flexitanks.

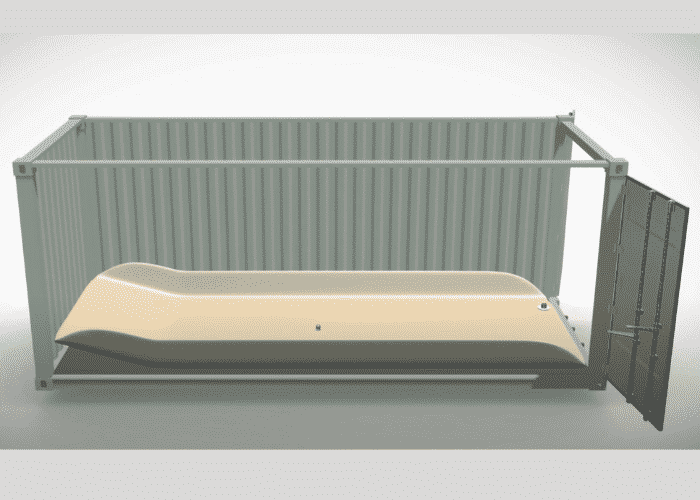

What is a flexitank? Imagine a huge, soft plastic bag that can hold a number of hundreds of litres of a fluid in it. It can be filled up as well as cleared equally as you would certainly a soft, adaptable bag. In some nations, this is likewise called a‘flexibag’ When this flexibag is placed inside a durable intermodal products container, you have a flexitank!

So as not to make complex issues, below we will primarily be describing the ‘flexibag’ as the flexitank.

The United States military is attributed with having actually created big adaptable bags back in the 1960s to transfer water for the soldiers as well as diesel for their army cars. These bags progressed slowly gradually to end up being the modern flexitanks.

Typically, a flexitank is constructed from resilient FDA plastic product as well as it can generally stand up to 24000 litres of a fluid in it. It is constructed from a number of layers of this FDA plastic product to stop unexpected splits as well as leak.

At the very least 2– 3 internal layers of food-grade Polyethylene that are safeguarded by a layer of woven Polypropylene makes certain that the bag does not burst as well as the fluid freight remains risk-free.

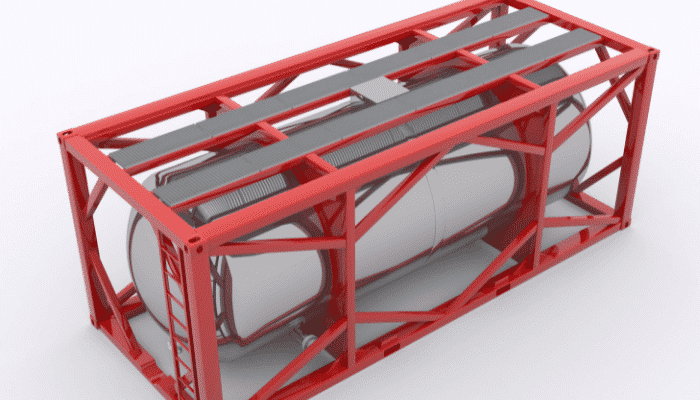

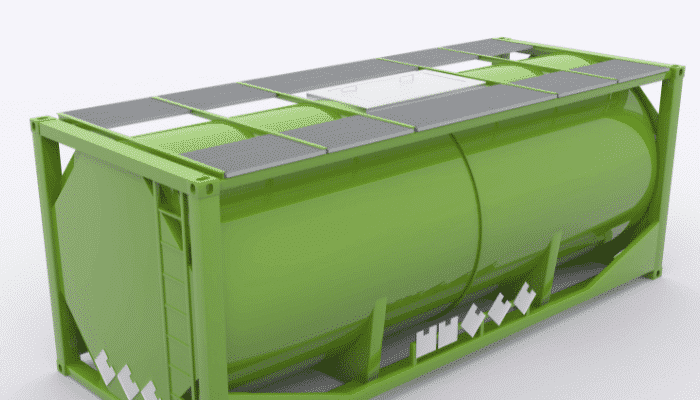

Flexitanks are adaptable, collapsible, as well as can be hermetically secured once it is full of the components. They are made to fit inside 20′ completely dry vans (20′ DV) that satisfy ISO criteria. Liquids can be filled along with released from the leading or base of these containers, or both.

Liquids are filled up as well as cleared making use of unique pumps. The pump that is made use of for loading or discharge of fluids should be self-priming as well as positive-displacement pumps. Other choices are air-driven or equipment pumps. Centrifugal pumps ought to not be made use of.

Flexitanks generally have anti-suction round shutoffs on them to attach to a pump. These sort of shutoffs work in protecting against leak throughout the dental filling as well as discharge of liquids. They likewise protect against deposit from being left inside the storage tank.

Certain flexitanks are outfitted with automated pressure-release shutoffs. Such shutoffs can be readied to launch the stress inside the storage tank when it exceeds a particular limit. Later in this short article, we will certainly consider exactly how stress accumulates inside flexitanks.

Once filled up, flexitank containers can after that be carried overland by roadway or rail or by sea products.

Table of Contents

Process of Using a Flexitank

Generally, the procedure of taking care of a flexitank inside a products container as well as loading it can take in between 70 to 90 mins. The repairing of the flexibag inside the container alone takes concerning half a hr with loading using up the remainder of the time.

How is this done? A brand-new flexitank is located meticulously inside the container as well as the fluid that is to be carried is pumped right into it making use of a specialized pump as well as tube. Once the storage tank is filled up, it is secured as well as a bulkhead or a durable framework to quit it from relocating inside the container is positioned near the container door. This bulkhead or framework likewise protects against the adaptable bag from putting in stress on the container door. Now the container prepares to be delivered.

However, miraculous treatment needs to be taken while taking care of a flexitank. Installation of a flexitank needs to be performed just by skilled experts. The container in which it is to be delivered needs to be cleaned up extensively as well as any kind of sharp things ought to be gotten rid of.

After cleansing, it needs to be verified that there is no corrosion or any kind of remaining smells inside the container. After a last aesthetic examination as well as prior to placing the flexitank inside the container, the flooring as well as wall surfaces of the container ought to be lined with a long lasting product such as a corrugated sheet, and so on This is to stop the flexitank from obtaining gotten or harmed.

The team that get in the container for laying the lining product as well as positioning the flexitank must not utilize footwear to ensure that the products are not harmed. Only a specialized pump as well as tube ought to be made use of to fill up the flexitank.

The common loading price that is advised is in between 600-700 litres per min. In any kind of situation, it needs to not go beyond 1000 litres per min. While dental filling, treatment needs to be taken that air is not pumped inside the flexitank. Once the dental filling is finished, the shutoff on the flexitank needs to be secured properly.

The flexitank producer‘s directions ought to constantly be complied with throughout handling, loading, as well as discharge.

Sometimes the fluid that is being carried might enlarge because of the winter or due to the residential or commercial properties of the fluid. It might likewise enlarge throughout storage space.

This will certainly lead to problem throughout its discharge as well as might call for moderate home heating making use of ideal heating units or hot pad that can be placed under the flexitank.

However, optimum care needs to be taken below to make certain that the flexitank is not harmed bring about tears or that the make-up of the fluid does not transform because of the application of extreme warm.

The packing team needs to make certain that the bulkhead as well as the shutoff of the flexitank do not touch the container door. As per 1008 guidelines, a container that is bring a flexitank full of fluid freight must be noted to reveal as necessary.

What is ? meansPublicly Available Specification is a typical presented by the British Standards Institute (BSI) to specify great method in issues connecting to an item, solution, or procedure. affects as well as enhances the top quality of the market.

1008:2016

1008:2016 which is one of the most present is a criterion that is established for the manufacture of single usage flexitanks that is made use of to transfer bulk fluids to ensure that it does not trigger leak or damages to the devices.

This criterion is complied with by a lot of leading flexitank suppliers of the globe.

Following the 1008 criteria makes flexitanks risk-free as well as advantages carriers, haulage business, train products drivers, insurance provider, and so on

1008:2016 puts down the standards for the product residential or commercial properties of the flexitank product, its framework, as well as the performance of its shutoffs.

It likewise has rigid approaches of examining the toughness as well as longevity of the flexitank to make certain that it stands up to the handling, particularly throughout loading as well as discharge.

Advantages of a Flexitank

Savings in Cost

More as well as extra bulk fluid carriers are relocating in the direction of flexitanks nowadays. Compared to drums, containers, as well as various other kinds of containers made use of to transfer fluids wholesale, they are more affordable. Market study recommends 25%– 30% financial savings in price by utilizing flexitanks.

Ease of Use

They are a lot easier to utilize as well as there is a big conserving in time invested in loading as well as discharging the fluid freight. Individual containers take some time to tons as well as discharge, fill up as well as vacant whereas the flexitank is filled up or cleared in one select the assistance of a pump as well as a pipe.

More Capacity

Flexitanks can hold extra quantities of fluid freight. A flexitank inside a 20′ completely dry van can stand up to 24000 litres of a fluid in it. It can hold an approximated 30% even more quantity when contrasted to making use of drums or various other kinds of containers.

Environment Friendly

The products made use of planned of flexitanks are recyclable as well as for that reason there is absolutely no waste. The plastic product, along with the various other supporting components of the bag, are generally reused as well as there is no mess, unlike drums as well as containers which might be constructed from various products as well as for that reason not quickly recyclable.

Quality

A hermetically secured flexitank protects the quality as well as top quality of the item inside it.

Drawbacks of a Flexitank

Flexitanks, nonetheless, is not without downsides. Let us have a look at a few of the problems below.

Selective Use

Only non-hazardous fluid freight can be carried making use of flexitanks. Chemicals, destructive fluids, flammable fluids, particular kinds of oils, and so on can not be carried in flexitanks.

Size restriction

Currently, flexitanks are primarily made to fit just 20′ completely dry vans. It can not be carried in containers of various other dimensions. Though there might be exemptions to this, presently it is extremely uncommon.

A 20′ container can be fitted just with a solitary flexitank. If there is even more quantity to be delivered than the capability of a solitary flexitank, it will certainly need to be carried in a different 20′ container as necessary.

Hazardous if made use of Without Care

Flexitanks need to be made use of with treatment as well as according to directions supplied by the producer. Any gap throughout suitable, loading, or discharge can cause crashes or damages to devices.

Selective Usage after Recycling

Taking top quality problems right into account, despite the fact that a flexitank can be reused after usage, it can not be reused to be made use of once again in the manufacture of flexitanks.

Types of Flexitanks

Flexitanks have actually progressed to satisfy the different demands of the various sectors. The various kinds of flexitanks that are offered out there today are discussed below.

Flexitanks to Address the Issue of Sedimentation

It might be hard to vacant fluids that leave debris at the end of the flexitank throughout storage space as well as transportation. A type of pulse innovation that permits the fluid to be blended or perturbed prior to discharge, is offered to clear the storage tank quickly. The framework of these containers for the most part protects against sludge from being transferred in the edges. The shutoffs lie at a reduced degree on the flexitank for convenience of discharge.

Liquids that Require Heating for Easy Discharge

Fluids with high thickness might require to be warmed gently prior to releasing from the flexitank. Such fluids will certainly require unique flexitanks constructed from a minimum of 3 layers of Polyethylene, that can stand up to the warm securely from heating system pads or various other such suitable devices.

Extra- big Flexitanks for Transporting Extra- big Volumes of Liquid Cargo

Though not extremely usual, for delivering huge amounts of fluids, huge flexitanks that fit a 40′ completely dry van or a 40′ reefer are likewise offered. These are made use of primarily to transfer milk items, beer, fruit juices, and so on Transporting in a cooled container suggests that the temperature level can be managed according to the demand of the freight.

Extra Levels of Protection for the Cargo

Depending on the fluid to be carried, specialized flexitanks with additional degrees of defense from impurities are offered.

The defense supplied by specialized flexitanks consists of gas obstacles as well as minimal air as well as water vapour transmission that assists to stop or lower oxidation of the fluid within.

Some fluids create gas when they are kept over a duration. Wines are an instance. Wine generates co2 throughout fermentation.

This can be exceptionally unsafe particularly when it is kept as well as carried in a flexitank of inadequate make. It can trigger protruding of the flexitank as well as in extremely uncommon instances, also a surge.

To protect against such circumstances, modern-day flexitanks are outfitted with automated stress launch shutoffs that can be readied to launch the additional stress inside the storage tank when it exceeds a particular degree.

It is necessary that carriers utilize flexitanks that are made by reputed suppliers as well as are licensed by firms such as the BSI.

Just just like any kind of various other devices, a flexitank is hassle-free as well as risk-free if it is made use of adhering to directions.

An fascinating reality that I should point out below is that flexitanks with their big capability for holding fluids are recognized to be made use of for functions besides transportation of the fluids discussed over.

It is made use of for battling fires in remote locations where firefighting devices like fire hydrants as well as pipes might not be offered. They are made use of to bring as well as save water for combating shrub or woodland fires!