What is Integrated Logistics Management?

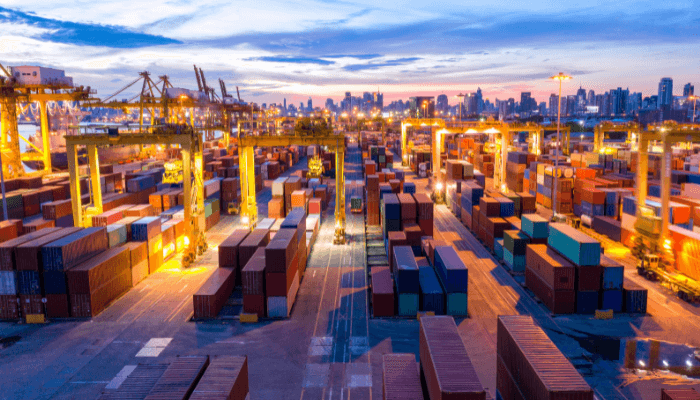

The logistics sector includes a number of principals that make certain the smooth circulation of resources, elements, and also ended up items.

Manufacturing plants take resources or elements from distributors. Such plants after that relocate the ended up items to suppliers or the retail market available for sale to the end-user.

Facilitating this action are the carriers, the forwarding and also removing representatives, and also different other gamers such as financial institutions and also federal government firms.

To area points right into point of view, allow us have a look at some numbers from the World Trade Organization (WTO).

United States buck 17.6 trillion well worth of product was sold 2020. This is about 1.4 trillion much less than the numbers of 2019! The range of logistics that would certainly have entered into relocating this product in between customer and also vendor is just to be envisioned!

Modern days logistics procedures normally include the complying with divisions:

- Purchasing

- Transport and also customizeds cleaning

- Storage and also supply handling (warehousing)

- Distribution and also turn around logistics

- Information and also high quality systems

This develops the supply chain that is the foundation of the majority of organizations on the planet. Overall, it is vital to stabilize supply and also consumer needs.

Earlier, the majority of companies watched each of these tasks as stand-alone procedures. Procurement, production, transportation, customizeds clearance, storage space, handling, and also forwarding divisions functioned as silos.

Quite commonly, a number of disconnects in between the performance of the different divisions brought about turmoil and also malfunction of procedures. There was financial loss in addition to loss in time effectiveness.

Soon sufficient, with expanding globe profession and also technologies in the approaches of operating, this circumstance transformed. Developments on the technological and also software application fronts assisted produce teamwork in between divisions.

Integrated logistics monitoring was a straight end result in which all the logistics divisions that earlier run as silos were united as a smooth feature. It assisted stakeholders accomplish effectiveness in time in addition to expense. Logistics framework and also employees can be propounded maximum usage.

Integrated logistics monitoring systems functioned as the stimulant to accomplish effectiveness in logistics procedures and also make the most of the earnings of companies.

An incorporated logistics distributor supervises of the whole supply chain for its consumer.

Integrated logistics monitoring unites the various interior features of the company, lines up, and also blends them with those of its distributors and also various other provider such as a carrier or a cleaning and also forwarding representative.

Coordination is crucial to incorporated logistics monitoring. It unites the different divisions within a company, their procedures, and also sources. Though they remain to operate as different procedures, these divisions are straightened for smooth procedure as a solitary, adaptable, huge device. There is far better cooperation in between divisions and also even more presence of information.

The COVID-19 pandemic has actually just strengthened the demand for companies to be able to swiftly reduce their company or range it up as needed by the market.

Organizations that have actually incorporated logistics monitoring systems are much better furnished to satisfy such backups as their different divisions run with optimum cooperation and also remain in a much better placement to expect changing needs.

Most logistics companies have actually embraced the incorporated logistics monitoring version to maximize their procedures, remove wastes, accelerate consumer feedback time, and also make the most of earnings.

The Main Objectives of Integrated Logistics Management

What are the primary goals of incorporated logistics monitoring? While companies might embrace this version to accomplish a number of goals, the primary ones might be detailed as adheres to:

- Increased effectiveness in procedures

- Increased effectiveness in supply monitoring

- Increased consumer fulfilment

- Reduction in functional prices

- Maximization of revenue

Increased Efficiencies in Operations

Operational effectiveness of logistics companies are enhanced when the various divisions within them share their efficiency information on a real-time basis.

Assets can be used in the very best feasible way, without needing to buy extra resources. Integration of the various tasks done by logistics divisions provides presence of the procedure all at once to the principals in addition to the monitoring of the company.

Processes can be structured to fit the procedures far better and also decision-making is simplified based upon strong realities and also numbers. Complex troubles can be ironed out with assimilation and also cooperation in between divisions.

Increased Efficiency in Inventory Management

Inventory monitoring is one more location that stands to profit by bringing the various procedures with each other. The procedures of order, transportation, clearance, incoming distribution, storage space, outgoing distribution to consumers, and also turn around logistics are all related and also can be incorporated to take care of a company‘s supply and also supply handling much better.

Real- time details assists a company‘s monitoring to take healthy and also prompt choices and also to apply them. Optimizing the storage facility format based upon awaited invoices and also distribution patterns and also picking the very best selecting techniques is an instance of what can be accomplished with incorporated logistics monitoring.

This can, consequently, aid the company‘s consumers decrease their financial investment in framework and also upkeep therefore causing enhanced expense financial savings.

Increased Customer Fulfillment

Typically, consumer satisfaction arises from satisfying the assumptions of the consumer. Anticipating the consumer‘s demands in regards to buy from the distributor, transportation, customizeds clearance and also storage space, distribution, devices, and also turn around logistics is crucial to consumer satisfaction.

Accurate and also real-time information assists consumers in preparation. It assists them expect needs and also see the investing in patterns of their consumers. Modern incorporated logistics monitoring systems can give consumers accessibility to this dependable and also real-time information.

Reduction in Operational Costs and also Maximization of Profit

Streamlined procedures therefore the assimilation of procedures cause financial savings on labor, devices, storage area, decrease of waste, and also most significantly, consumer fulfillment. These effectiveness convert right into financial savings.

The internet outcome might be summarized as enhanced revenue margins to the company therefore the lowered functional prices and also enhanced consumer fulfillment.

The consumer additionally advantages by means of not needing to buy huge framework to manage their supply. Reduced functional prices of a logistics company are commonly handed down to their consumers using lowered prices.

Leading logistics business take advantage of incorporated monitoring systems to enhance their experience and also high quality of solutions. Customers therefore obtain the advantage of specialist, end-to-end logistics to satisfy their objectives.

Integrated logistics monitoring systems produce openness in operating, clear presence of information, and also convenience of connecting in between specialist logistics provider and also their consumers.