If your freight is incredibly big or has unwieldy booms as well as projections that do not fit right into conventional delivery containers after that you have an out of scale freight available, reduced to OOG freight.

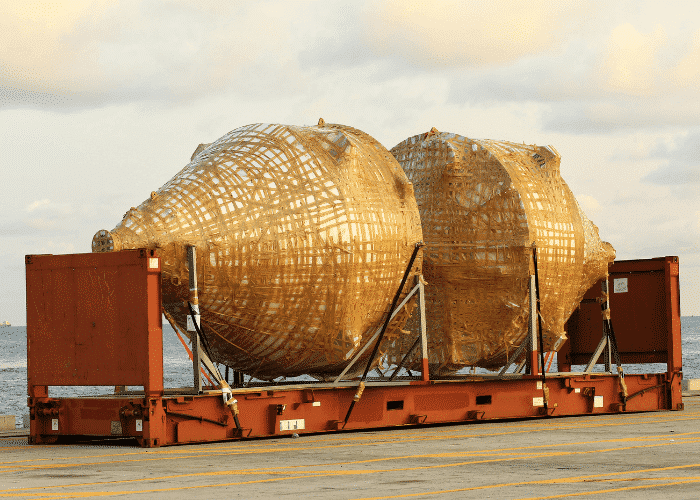

The checklist of OOG freight is long. Some instances are huge vehicles such as deluxe trainers, vehicle trailers, airplane components, components of wind generators, building and construction equipment, unusually big components of equipment utilized in electrical energy generation, and so on

Also described as AILs (Abnormally designed Indivisible Loads), such out of scale freight go beyond conventional container measurements as well as perhaps very hefty to be fit in rectangle-shaped delivery containers such as a twenty feet container (TEU) or a forty feet container (FEU).

The large measurements as well as weight of such odd-shaped as well as odd-sized freight call for customized durable tools to manage them for transportation by sea.

Unless they are taken care of with treatment as well as accuracy, such freight can quickly obtain harmed throughout transportation.

Cost of Transporting Out of Gauge Cargo

Transporting out of scale freight can be a pricey event as it includes added expenses. The unfit freight consumes right into area that might have been utilized for various other freight.

When an OOG freight is filled on the deck or below-deck of a freight service provider, neither can an additional container be positioned as well as safeguarded to the twist-locks on the surrounding sides of it neither can containers be positioned on top of the OOG freight, as in level shelfs as well as system containers.

Hence, the delivery as well as transportation firms bill additional to offset this lost area. Space therefore lost is additionally described as ‘lost slots’.

Planning as well as Execution

An out of scale freight, otherwise safeguarded or lashed correctly to their containers can harm various other freight that is maintained near it. Besides, when out of scale freight is positioned onboard a vessel, its area needs to be prepared very carefully as there will certainly be various other freight that will certainly need to be unloaded prior to the OOG freight.

It is not just the sea trip of the OOG freight that needs to be prepared as well as implemented appropriately however additionally the overland transportation from the factory or its storage space area to the port of loading.

Since some out of scale freight might have unusual projections or might be incredibly hefty, the sort of trailer vehicle to be utilized for relocate as well as the ideal gantry crane need to be selected very carefully as well as organized. Next, the roadway course to be extracted from the OOG freight storage space area to the port, approximately the loading factor, needs to be prepared.

The course to the port need to be prepared as though active roadways as well as peak hrs are stayed clear of. There need to suffice clearance on either side of the roadway as well as ahead (over bridges, arcs, and so on) for the OOG freight to pass securely as well as additionally not to harm building.

Equipment

The most usual alternatives offered for the transportation of out of scale freight is level shelfs or open-top containers.

A level shelf container normally has retractable wall surfaces at either end of the container. The sides of the container are open as well as do not have wall surfaces.

Out of scale freight can be filled in such containers from the sides or the top. When packing is from the side, it is usually done making use of durable forklifts.

If the freight is filled from the top, it is done making use of cranes. The freight is normally positioned in the centre of the container for optimum weight circulation.

Unlike a level shelf, the open-top container has inflexible wall surfaces along its size as well as doors on among its ends, like the standard containers. However, the top is open or it might have a detachable difficult roofing system. The difficult roofing system can be eliminated making use of a crane. Sideloading is not feasible in open-top containers as they have inflexible wall surfaces along the sides. Hence it is done via the door making use of a durable forklift or from the top making use of a crane.

In some sort of open-top containers, the light beam atop the door can be taken down to help with the loading of scale freight via the door.

To aid the motion of durable forklifts right into the container several of the doors can be rotated external.

Once the out of scale freight is filled, the freight might be lashed to the flooring of the container safely making use of bands. The open-top is after that covered with a tough sheet such as tarpaulin or with the container roofing system.

Tarpaulin is a durable, versatile product that is generally utilized to cover such containers or the out of scale freight. It is normally made from canvas covered with polyurethane or polyethene or various other such water-proof plastics. It is rather flexible as well as will certainly additionally comply with the form of the out of scale freight. Plastic or canvas sheets can additionally be utilized to cover the container or freight.

Most level shelfs have pad-eyes or lashing-rings on their flooring for lashing the out of scale freight or for linking the tarpaulin cover.

Flat shelfs as well as open leading containers utilized in the transportation of out of scale freight are mainly of the conventional dimensions of 20 feet as well as 40 feet. This is to make sure that they fit on conventional trailers as well as can be dealt with by the conventional loading/unloading tools at ports as well as storage facilities quickly.

Most of these containers have actually floorings made from wood.

Flat Rack Containers

Flat shelfs are usually discovered in sizes of 40 feet as well as 20 feet. Out of scale freight can be filled on them from the sides making use of durable forklifts or positioned on the flooring from the top making use of a crane. They are consequently ideal for freight such as abnormally-shaped equipment, watercrafts, long tubular frameworks, and so on

A common 40 feet level shelf container has measurements of 40′ x 8′ x 8′ 6″ (elevation of completion wall surfaces) as well as they lug a haul of about 25 loads. When the freight is long or also wide as well as does not fit on a solitary level shelf, 2 or greater than 2 level shelfs are linked to hold the freight.

A 20 feet level shelf container has measurements of 20′ x 8′ x 8′ 6″ (elevation of completion wall surfaces) as well as they lug a haul of about 22 loads.

One benefit of level shelf containers is that vacant level shelfs can be piled one in addition to the various other throughout storage space to conserve area.

Open Top Containers

Open leading containers additionally are available in dimensions of 40 feet as well as 20 feet, though customized containers are additionally offered for unique freight. In such containers, freight is normally filled from the top making use of a crane or via the door making use of a durable forklift.

A 40 feet open leading container has measurements of 40′ x 8′ x 8′ 6″. These containers can lug a weight of approximately 26 loads.

A 20 feet open top has measurements of 20′ x 8′ x 8′ 6″ (elevation of completion wall surfaces) as well as they lug a haul of about 28 loads.

The measurements as well as haul capability modification in between various make from containers as well as container collection.

Flatbeds or Platform Containers

Flatbeds or system containers are additionally utilized to deliver out of scale freight. As the name indicates, they do not have any kind of wall surfaces or a roofing system as well as for this reason the only limitation to comply with is the weight of the OOG freight.

A 20 feet flatbed with a floor-length of 19.88 feet has a haul of 31 loads. 40 feet flat beds can be found in sizes of 39.99 feet each, with a haul capability of 39 loads.

Like level shelf containers, flatbed containers can additionally be piled one in addition to the various other throughout storage space or transportation of empties.

Payload

Why is the haul capability in between 20 feet as well as 40 feet containers out of proportion? If a 20 feet open leading container can hold 28 loads, should not the 40 feet hold 56 loads?

This anomaly in haul in between both dimensions of containers is as a result of the container style as well as weight limitations of these layouts. Carrying excess weight than what is recommended by the container maker can lead to “container drooping‘.

The container can break under the excess weight triggering damages to the freight as well as various other crashes.

Different nations might have various restrictions on container hauls. Since some out of scale freight evaluate greater than the recommended limitation, it is usually taken apart as well as moved as components and after that later on reconstructed after reaching its location.

Most of the containers that are utilized for lugging freight have Safety Approval Plates according to the CSC 1972 (Convention for Safe Containers 1972). This plate that is chosen the container reveals all the information of the container style as well as most notably its gross weight. The gross weight is displayed in both kgs along with extra pounds.

Gross weight is the complete weight of the container as well as the haul it can lug. According to the CSC 1972, containers need to go through assessment at the container depot by licensed assessors within 5 years of the day of its manufacture as well as afterwards, as soon as every 30 months to identify as well as accredit their sea as well as road-worthiness.

Convention for Safe Containers 1972 (CSC 1972)

The International Maritime Organization (IMO) as well as the United Nations (UN) collectively promoted a collection of treatments for the handling of containers to make sure human security throughout the transportation of such containers. It established consistent worldwide security policies to stay clear of complication brought on by the numerous policies of various nations.

While the CSC 1972 relates to the majority of transportation containers, it, nonetheless, covers just containers of a suggested minimum dimension. Containers that are covered under the CSC 1972 must be fitted with the Safety Approval Plate revealing all the technological information concerning the container as well as its gross weight.

Over the last couple of years, numerous modifications have actually been presented to the initial collection of regulations of CSC 1972 to include added security as well as safety actions.

Types of Cargo

Carriers transportation freight crammed in containers, as completely dry mass (mineral ores, grains, and so on), break-bulk (out of scale freight, oil drums, and so on), fluid mass (petroleum, edible oil, and so on), as well as RO-RO or ROLL-ON/ROLL-OFF (usually vehicles that are driven right into the service provider‘s hold for transportation as well as eliminated of it upon getting to the location).

The measurements or weight of some out of scale freight might go beyond the restrictions that regular tools such as level shelfs, open tops, or system containers can manage.

In such situations, it is often safeguarded to the vessel straight, after taking into account the security of the freight, the vessel, as well as various other freight that are maintained near the OOG freight.

Monitoring Out of Gauge Cargo Onboard Ships

The deck police officers of a freight vessel are usually accountable of looking after the loading as well as dumping of freight. They job according to a loading/unloading strategy which is ready very carefully. Slots to be left uninhabited beside the out of scale freight should be prepared.

For below-deck storage space, the hatch cover clearance should be taken into consideration to stay clear of any kind of damages to the freight or the vessel. An also tons onboard the vessel as well as an also release strategy avoid the listing of the vessel specifically when extremely hefty out of scale freight exists onboard the ship.

Good understanding of the ballast procedures as well as connected tools aid deck police officers in their task. They need to make sure that OOG freight is taken care of to the twist-locks as well as lashed correctly to the deck.

Rough seas can usually create these ahead loosened as well as consequently the deck police officers should carry out regular guidance throughout the cruising.

Out of Gauge Rate

Shipping firms normally call for the adhering to info from the carrier to give them with a price for transportation of the out of scale freight.

- Description of the out of scale freight.

- Dimensions (lengthiest size x widest size x highest elevation).

- Weight of the OOG freight in kgs.

- Point of packing.

- Point of discharge.

- Photos or illustrations (front, side, as well as leading sights) revealing the center of gravity.

- Lifting factors of the OOG freight.

- Special directions, if any kind of.

Transferring as well as moving out of scale freight calls for a group of specialists that can intend as well as carry out the handling as well as transportation of such freight from its factor of beginning to the location.

Most leading delivery as well as transportation firms have different groups to manage OOG freight consignments.