The steel additive production market will certainly be adversely influenced by the 2020 pandemic. Despite this short-to-mid-term obstacle, the market is anticipated to climb and also surpass $10Bn within the following 10-years. The arising and also developed printer gamers order almost all of the headings, however the majority of this projection yearly income will certainly remain in product sales in which there is fantastic untapped possibility.

In the most recent market record from IDTechEx, ‘Metal Additive Manufacturing 2020-2030’, the market projection to diminish and afterwards climb to over $10Bn with the majority of that yearly income in product sales. This technological market record consists of granular projections and also over 50 firm accounts from appealing startups with to market leaders, product gamers, and also much more. This was finished with a comprehensive variety of key meetings to bring the visitor the most recent and also most exact info.

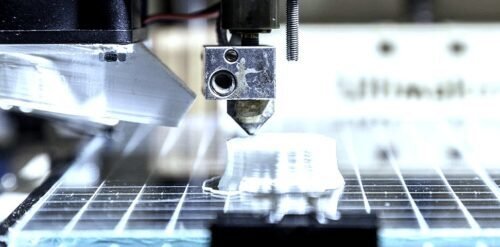

The products profile for AM procedures was mainly based upon the alteration of existing products and also supply chains. Metal powders are one of the most typical kind of feedstock utilized with titanium, steels, light weight aluminum, nickel-based, cobalt-based, copper, rare-earth elements, and also much more all used. Titanium is one of the most considerable and also there is considerable motion in this market, with growths (such as Sandvik, Oerlikon, and also Tekna), upright assimilation within essential verticals (such as GE Additive and also Carpenter), and also joint endeavors (such as GKN with TLS Technik).

There is additionally comprehensive passion from existing steel powder gamers that see this market as both a possibility and also a danger. However, atomization procedures are not accomplished, especially for the similarity titanium, and also as commonly reduced producing the business economics behind it can be testing which maintains suitable product pricey. Not to state that the pureness, dimension circulation, and also form all require essential factors to consider. There is a vital pattern in operation various other steel feedstocks, with cord being one of the most significant; this will certainly be gone over in a succeeding write-up.

Common objections of the steel profile for additive production is that they are pricey, generally customized from existing products, and also do not take advantage of the complete possibility of the procedures. The present gamers have actually been quickly transforming that however there is additionally the possibility for interruption. This write-up will certainly highlight 9 startups that are aiming to make an influence in this market. They go to different levels of innovation preparedness and also have varying techniques. Despite the long-lasting market possibility, success is anything however ensured, you just need to take a look at the disturbance of Metalysis (not consisted of on the checklist because of this) to see that. There are common obstacles in the timing, offering, and also organization design to be affordable and also well-positioned to accomplish a share of this market.

New Processes

There are brand-new techniques in powder manufacturing. 6K (formerly Amastan Technology) utilize a microwave plasma system with a really high return for Inconel and also titanium alloy manufacturing, and also Equispheres utilize an unique strategy to create very round powders with a slim fragment dimension circulation. Both these firms have actually increased significant financing over current years as they start to increase in the direction of significant industrial manufacturing. Uniformity Labs has actually created a strategy to make denser fragments, and also like with Equispheres’ very round regular powders, this can permit a lot greater throughputs in the printer procedure.

Recycled Feedstocks

A significant vehicle driver in aerospace for additively making titanium components is to minimize the buy-to-fly proportion. This is for the expense of the virgin product and also the handling and also re-use of the scrap. One target is to transform scrap titanium right into useful AM powder and also upcycled titanium components. Tekna and also 6K, formerly pointed out, are both proceeding this area, with 6K getting AL Solutions for this. Another start-up energetic right here is MolyWorks with interesting operate in their growth of a mobile shop.

Aluminum, Steels, Copper, and also MMCs

As gone over, titanium is just one of one of the most significant product feedstocks for additive production, however designers would certainly such as a broader array especially with lower-cost light weight aluminum and also steel alloys that they have a huge history in. Equispheres, pointed out previously, are originally targeting light weight aluminum alloys seeing this void out there. Elementum 3D has a proprietary Reactive Additive Manufacturing (RAM) procedure where in-situ response items get rid of typical obstacles with grain frameworks and also even more. Elementum 3D has actually gotten financing and also are scaling their profile that include 6000 and also 7000 collection light weight aluminum in addition to steel matrix composite (MMC) offerings. MMCs have actually been understood for a long period of time however have actually just reached particular particular niche duties, AM can broaden this and also early-stage MMC gamers, the similarity Gamma Alloys, are beginning to concentrate on this alternative.

When we take a look at inexpensive mid to high-volume items, steel is the leading product; steel is currently supplied for a lot of procedures and also a front jogger in bound steel and also steel binder jetting procedures revealing the value. Formetrix spun-out from NanoSteel in 2018 and also are targeting their exclusive device steels for AM procedures. Finally, copper is product that can take this innovation in countless instructions. There are several obstacles however with an enhancing variety of arising offerings, it is simply an issue of time prior to this removes.

Materials Informatics

Materials Informatics is the data-centric strategy for products scientific research R&D, made it possible for by boosted information facilities and also artificial intelligence techniques. IDTechEx has a thorough record on the subject:“Materials Informatics 2020-2030” One target audience are additive production alloys, QuesTek Innovations, Intellegens, Exponential Technologies, and also Citrine Informatics have actually all been energetic in this area, with the last collaborating with HRL Laboratories to generate an AM light weight aluminum alloy signed up by theAluminium Association As well as providing systems and also research study tasks several additionally utilize these sophisticated R&D techniques to construct IP profiles. OxMet Technologies bring this out for several alloys, especially high-temperature nickel-superalloys, and also Phaseshift Technologies target amorphous alloys utilizing the quick air conditioning price of the printing procedure.

Exotic Materials

Amorphous alloys and also MMCs are acquiring importance with additive production in a manner that was formerly not feasible. Heraeus go to the leading edge of deal with amorphous alloys in AM making a variety of demo components. This development to past standard alloys is of considerable possibility to the additive production market and also is best highlighted in High Entropy Alloys (HEAs); HEAs have actually been an R&D passion for an extended period however AM can hold the secret to opening their possibility. There is a wonderful series of task occurring in the products profile for steel additive production. QuesTek Innovations and also Metalysis have actually both been energetic in this area, however of note was 6K operate in asserting to publish the globe’s very first component at the end of 2019.

Sea News Feature, August 11