abdominal has actually approved Approval in Principle (AIP) to the Shanghai Merchant Ship Design and also Research Institute (SDARI) for its vessel style with an unique aft design, which removes contamination and also advertises effective vessel procedures.

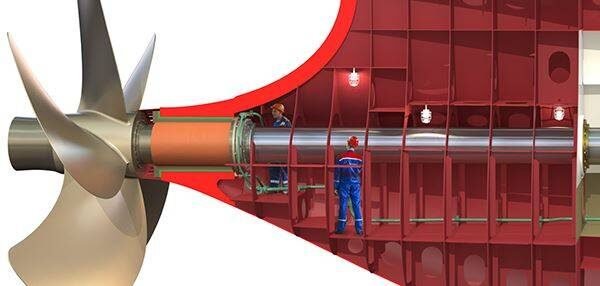

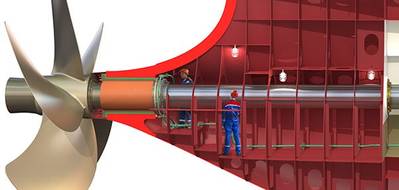

The SDARI style, established together withThordon Bearings Inc and also the National Technical University of Athens (NTUA), presents a brand-new technique to the vessel’s aft design, consisting of elimination of the strict tube spreading, utilizing salt water for lubrication and also production of a chamber to allow in-water upkeep for the very first time.

These advancements allow shipyards and also proprietors to get rid of shaft-bearing oil leakages, streamline upkeep and also reduced expenses.

Using salt water for lubrication of the strict tube bearing eliminates the threat of oil leak. By making it possible for designers and also shipyard artisans to access the strict tube without the demand for drydocking, the off-hire time sustained for birthing assessment and also substitute will certainly avoid 2 weeks to eventually while afloat.

The installment of a proper torsional resonance damper can additionally get rid of the Barred Speed Range, which exists in the substantial bulk of direct-drive diesel motor vessels. Therefore, the brand-new style can much better sustain streamlined conformity with environmental-focused laws, such as the Energy Efficiency Existing Ship Index (EEXI), and also can allow much more effective use the engine’s propulsive power, considering that the entire RPM variety of rates is readily available for constant procedure. It makes it possible for proprietors to quickly think about an Engine Power Limitation (EPL) if needed, to adhere to Carbon Intensity Indicator (CII) power outcome demands.

The resulting style proposition adheres to all abdominal regulations and also laws and also the tail shaft study can be kept at the optimum 15-year period if the abdominal TCM-W Notation is taken on.

“The concept of using seawater as a lubricant is well-established and the proposed design takes this further by removing the stern tube casting, decreasing the shaft line length, reducing the engine room space and increasing the cargo space. The elimination of the Barred Speed Range and the creation of an aft chamber to enable in-water inspection, enable significant efficiencies and cost savings for operators,” statedDr Chris Leontopoulos, Director of Global Ship Systems Center, ABDOMINAL MUSCLE Athens.

“Besides the benefits for operators, the new concept also gives more possibilities and flexibility for designers to optimize the engine room arrangement. Consequently, for the shipbuilding, the initial cost including the construction materials and labor cost may be reduced accordingly. It will contribute a series of benefits to all parts involved in the vessel,” statedMr Wang Gangyi, Chief Engineer, SDARI.

“Our technical discussions have led to a revolutionary propeller shaft bearing system design that offers easy monitoring and maintenance of bearing and seal condition without shaft withdrawal, lower operational expenses and elimination of oil emissions forever,” stated Anthony Hamilton, Technical Director, Thordon Bearings, Canada.