David Clark Company is greatest recognized throughout the marine marketplace for its wi-fi and digital headset workboat crew communication programs – the Series 9900 Wireless Marine Headset System and the Series 9100 Digital Marine Headset System. The firm has over 20 years of expertise designing and manufacturing boat crew communication options for quite a lot of workboats, e.g., patrol boats, hearth/rescue craft, and offshore service vessels.

But it’s possible you’ll not know that David Clark Company began out as a knitting manufacturing unit for making males’s and ladies’s specialty clothes and developed into a number one supplier of crucial communication options for high-noise environments and modern aerospace crew protecting tools. Here’s the way it occurred.

So, who was David Clark?

How does a small garment knitting firm in Worcester, Mass., find yourself changing into an iconic model and indelible a part of aviation and aerospace historical past? The reply is basically as a consequence of one man. A person who left faculty to go to work on the age of fifteen. A person who earned no diplomas after grammar faculty. A person who, not like some titans of enterprise in the present day, shunned the highlight and desired to face within the shadow of his accomplishments, preferring to bestow credit score upon people who “did the real work.” That man? David Myron Clark.

David Clark, founding father of David Clark Company, Worcester, Mass. (Photo: David Clark Company)

David Clark, founding father of David Clark Company, Worcester, Mass. (Photo: David Clark Company)

David Clark Company was integrated in Massachusetts in 1935 after creating a brand new idea of knitting two-way stretch cloth for males’s and ladies’s specialty undergarments. The knitted blanks had been bought to corset producers for stitching, ending and resale. Despite being wanting money and having the highest of its constructing blown off by a hurricane in 1938, the corporate persevered. In time, a complete of six patents for knitting had been utilized for and granted. In 1939, David Clark Company developed and patented a singular supporting undergarment for males referred to as “The Straightaway” (basically a compression garment for males) which bought in shops in New York and New England, and through unsolicited mail.

“G”-forces and the partial strain go well with

With America’s involvement in World War II seeming inevitable, David Clark, working by means of enterprise associates in Washington, D.C., approached the War division to think about prototype clothes which he had lately developed to deal with “the dreaded blackout”, or G-induced lack of consciousness amongst fighter pilots. It was by means of his contacts on the War Department that he was launched to E.J. Baldes, head of the division of Biophysics on the Mayo Clinic, in November of 1941. The two males would grow to be lifelong associates. David Clark remembers in his memoir, The Development of the Partial Pressure Suit, “We each had similar and great interests in aviation; I’d not worked at it at all, but he had worked with Drs. Boothby, Lovelace and Bulbullian – all at the forefront of aviation medical research – in the development of improved methods for supplying pilots with oxygen to breathe so that they might fly at higher altitudes. I presumed that I might be able to help develop some sort of protection from the ‘Dreaded Blackout’ experienced by pilots of high-performance aircraft when conducting high speed maneuvers in flight. I believed that I should offer my services and facilities to the government.”

David Clark quickly moved his firm into conflict mode, including stitching machines, and commenced making tent elements, jungle hammocks with insect netting and roofs, in addition to fragmentation bomb parachutes, on prime contracts. His ardour, nevertheless, was creating the “Anti-Blackout” (finally known as a “G”- Suit). With the assistance of the Department of Biophysics on the Mayo Clinic, the corporate fabricated 22 progressively improved designs.

Initially, the army was skeptical. Again, from his memoir, Clark recalled, “I wrote to the Commanding Officer at Wright Field [now Wright-Patterson Air Force Base] in Dayton, Ohio, and received a classic reply, ‘There is no existing data indicating that apparatus such as you describe would be helpful.’ I was to hear that many times, with only slight variations in the next few years.”

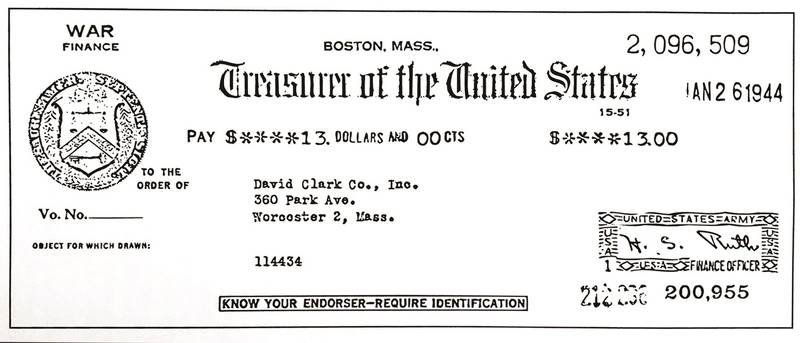

The first authorities test despatched to David Clark Company for its pioneering work on the partial strain “anti-g” go well with. The $13 test was by no means cashed and saved as a memento. (Photo: David Clark Company)

The first authorities test despatched to David Clark Company for its pioneering work on the partial strain “anti-g” go well with. The $13 test was by no means cashed and saved as a memento. (Photo: David Clark Company)

Undeterred, David Clark persevered. After experimenting with a number of go well with strain valve and inflatable bladder designs, the corporate acquired its first test from the federal government on June 2, 1944, for a partial strain anti-g go well with – made out for 13 {dollars}! Since then, David Clark Company’s contributions and accomplishments learn like a Who’s Who checklist of aerospace historical past:

The Red Bull soar

Among the numerous different accomplishments not listed above, some of the high-profile was the design and manufacture of the strain go well with worn by skydiver and adventurist Felix Baumgartner for the Red Bull Stratos Program. In October of 2012, Baumgartner jumped from a capsule 128,000 ft above earth (at the moment a world report), suspended in house by a balloon. He turned the primary human being to interrupt the pace of sound outdoors a car. Baumgartner landed by parachute safely within the New Mexico desert. The David Clark Company go well with carried out flawlessly.

Skydiver and adventurist Felix Baumgartner’s record-breaking soar in a strain go well with designed by David Clark Company. (Photo: David Clark Company)

Skydiver and adventurist Felix Baumgartner’s record-breaking soar in a strain go well with designed by David Clark Company. (Photo: David Clark Company)

Perceived by most as a “record breaking stunt” by thrill-seeking adventurists, the hassle was truly the end result of an in depth design, improvement, check and analysis (DDT&E) effort to advance the state-of-the-art for aerospace crew protecting tools, automobiles and associated escape programs. The soar from such an excessive altitude offered the corporate with vital information and knowledge on the efficiency capabilities of its go well with and occupant—data that has since been used to boost the design and manufacture of subsequent fits for army pilots and astronauts.

“Our support of the Red Bull Stratos Program was an opportunity for us to showcase our ongoing commitment to enhance the safety and performance of those who work in challenging environments every day, whether they be extreme altitudes, the vacuum of space, or in the realms associated with high-G flight,” stated Dan Barry, Vice President/Director of Research & Development at David Clark Company. “Mr. Clark recognized that the unique capabilities and expertise developed by his company represented a true, National asset, the preservation and advancement of which remains a core focus of our operations 88 years later.”

Hearing safety headsets

In 1952, David Clark was invited to be a visitor on a five-day coaching cruise on the F.D.R. plane service (the most important within the Navy fleet on the time) by Dr. Ralph Christy, a navy good friend of the then ‘Clark Company’, who was charged with Pilot and Flight Crew Protection. That invitation and the 5 days that ensued proved to be a significant turning level for the corporate. David Clark was shocked by the amount of noise on the service flight deck with jets taking off and touchdown. At a decibel price far exceeding the edge that may trigger everlasting listening to injury, Clark noticed some males had been additionally subjected to confusion by the noise. He was later knowledgeable that some had been injured and even killed by propellers and jet intakes.

Months later, whereas visiting the house of David Clark, Dr. Christy proposed that the Clark Company devise protecting units in opposition to the noise and the 2 started sketching out concepts. After a collection of prototypes had been examined, the 372-2 Hearing Protector acquired a patent in October 1953. By 1957, the Clark Company’s greatest yr as much as that point, greater than half the income had been derived from over-the-head model listening to protectors, with the USAF becoming a member of the U.S. Navy as main clients.

Inset: Vintage David Clark listening to protector, circa. 1953. Aircraft service Navy pilots on “Vultures Row” carrying modern-day David Clark listening to protectors. (Photo: David Clark Company)

Inset: Vintage David Clark listening to protector, circa. 1953. Aircraft service Navy pilots on “Vultures Row” carrying modern-day David Clark listening to protectors. (Photo: David Clark Company)

Aviation headset pioneers

During the early Seventies, David Clark Company started to broaden its focus in an effort present aviation pilots with headsets that present, not solely listening to safety from engine noise in loud plane cockpits, but additionally the power to speak clearly with ATC. This effort resulted within the introduction of one of many first, viable, communication headsets for aviation pilots: the Model 10BB/F.

Model H10-BB, David Clark’s first aviation headset manufactured in 1974. Today, David Clark provides the broadest line of aviation headsets within the business. (Photo: David Clark Company)

Model H10-BB, David Clark’s first aviation headset manufactured in 1974. Today, David Clark provides the broadest line of aviation headsets within the business. (Photo: David Clark Company)

Today, David Clark Company serves the overall aviation, industrial aviation, marine and army markets with the broadest line of fastened wing and rotary wing headsets within the aviation business, together with flagship fashions DC ONE-X and DC PRO-X2 Series energetic noise discount (ANR) headsets and the Model H10-13.4 passive noise-attenuating headset, the longest and best-selling headset in aviation.

Most fashionable David Clark aviation headset fashions in the present day, left to proper: DC PRO-X2 ANR Series, DC ONE-X ANR Series and the H10-13.4 passive noise-attenuating headset. (Photo: David Clark Company)

Most fashionable David Clark aviation headset fashions in the present day, left to proper: DC PRO-X2 ANR Series, DC ONE-X ANR Series and the H10-13.4 passive noise-attenuating headset. (Photo: David Clark Company)

Critical communication headset system options

By the mid-Eighties, the corporate continued to broaden its attain into new markets with the introduction of Wired Headset Communication Systems designed for airline/airport floor assist personnel, in addition to firefighters and first responders. These programs had been designed to supply clear communication and improve efficiency, security, and situational consciousness (whereas nonetheless offering listening to safety) for crews working in high-noise environments. Thousands of David Clark wired programs are nonetheless being utilized in these markets in the present day.

The creation of wi-fi and digital headset programs

Buoyed by the success of its wired headset programs, the David Clark Company solid forward with the introduction of the Series 9900 Wireless System in 2011. Wireless programs, that includes superior Digital Enhanced Cordless Telecommunications (DECT) know-how, present customers with all of the communication benefits of wired programs, whereas additionally offering the extra advantage of mobility and freedom of motion, with out being tethered to an equipment or different tools—an enormous profit for firefighters on the fireground and for floor assist personnel throughout plane pushback, deicing and different airport ramp and upkeep functions.

Series 9100 Digital Headset System elements, together with Communication Headsets, Master Station, Headset Station, Belt Station and Wireless Gateway. (Photo: David Clark Company)

Series 9100 Digital Headset System elements, together with Communication Headsets, Master Station, Headset Station, Belt Station and Wireless Gateway. (Photo: David Clark Company)

The Series 9100 Digital System, launched in 2017, affords workboat crews with the benefits of Scalability for a just about limitless variety of customers, Versatility with multi-channel programmability and the power to seamlessly combine wi-fi headsets for a “hybrid” wired/wi-fi communication answer, and Simplicity for ease of programming and operation. Wired and wi-fi functionality from the identical system enhances programming flexibility for a broader vary of mission necessities and creates extremely adaptable configuration schemes.

A sea change in workboat crew communications

In the early Nineties, David Clark Company took intention on the workboat section of the Marine market and launched the Series 9500 wired headset communication system for patrol boats, hearth/rescue craft, tug and tow boats, offshore service vessels and different specialised workboats. Having gained over 20 years of expertise within the marine market, the corporate shortly noticed the benefits of its Wireless and Digital Headset Systems for workboat crews.

Series 9900 Wireless Headset System elements, together with Communication Headsets, Belt Stations, and Wireless Gateway. (Photo: David Clark Company)

Series 9900 Wireless Headset System elements, together with Communication Headsets, Belt Stations, and Wireless Gateway. (Photo: David Clark Company)

The Series 9900 Wireless and Series 9100 Digital (wired) programs have each been nicely acquired by workboat crews worldwide, that includes rugged reliability, glorious headset consolation, and are constructed with marine-grade elements providing ingress safety, salt/fog corrosion resistance, extensive ranging temperature tolerance and superior shock/vibration absorption to face as much as harsh marine environments.