Technical inquiries to SRC Group ramped up after it obtained Approval in Principle (AIP) for an idea which ‘reinvented methanol fuel storage’ on board ships. Delivering the solutions has seen technical discuss changing into venture discussions

‘Green’ methanol has the power to in the future run vessels virtually emission-free, and industrial transport more and more investigates. Derived right now principally from pure fuel, methanol is nonetheless accessible, comparatively simple to deal with and predictable. Lower carbon right now, and probably zero carbon tomorrow, methanol gives a substitute for HFO, and a pathway in direction of decarbonization targets.

A chief problem to incorporating methanol as a maritime gasoline historically has been its house inefficiency, as ton-for-ton, it takes 2.4 occasions extra methanol to generate the equal vitality as HFO.

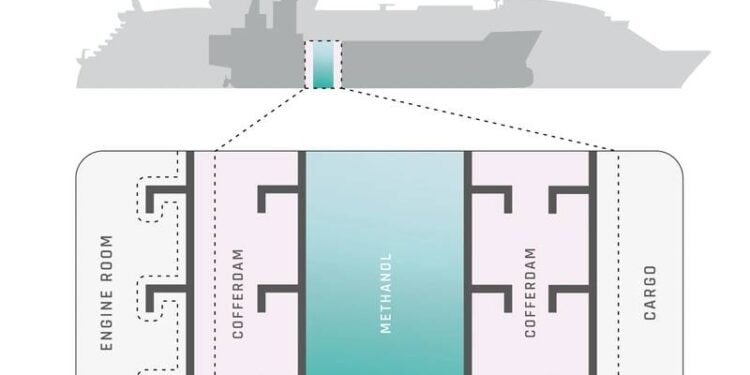

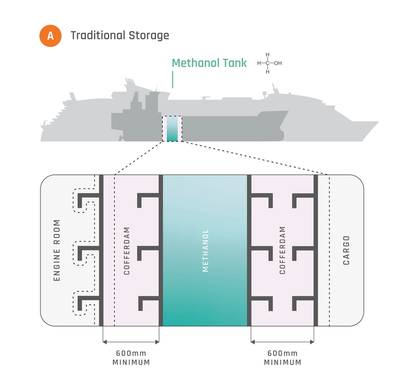

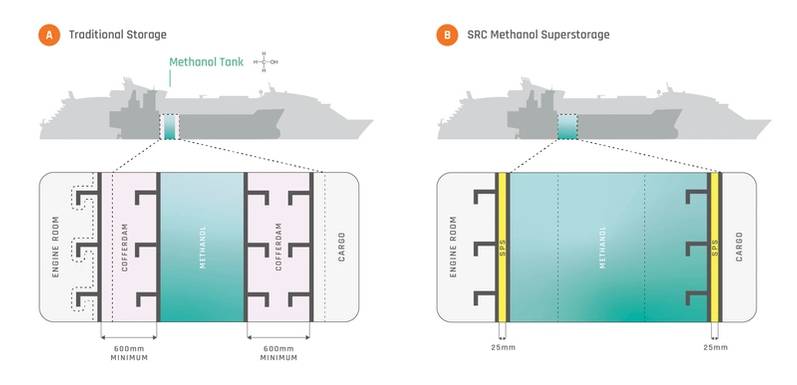

Conventionally, tanks storing low flashpoint fuels on board ship characteristic cofferdams of at the very least 600mm throughout to separate inner and exterior partitions. Included as a security precaution, the hole additionally restricts capability.

Imaginative design may help discover unused areas for further storage on board a newbuild ship, however alternatives are extra restricted on present vessels. Where retrofitting a twin gasoline engine to run on methanol is possible, the gasoline storage subject might prohibit a ship to brief voyages or demand extra frequent bunkering – each of which impression on ROI.

In October 2023 Lloyd’s Register granted Approval in Principle (AiP) for SRC Group’s ‘Methanol Superstorage,’ a retrofitted tank storage resolution that will increase quantity by 85%, in line with SRC, however may be put in with solely a minimal impression on the overall association.

Image courtesy SRC

Image courtesy SRC

Closing the Gap

Methanol Superstorage resolution dispenses with the cofferdam altogether and as an alternative installs tank partitions fashioned by sandwich panel system (SPS) know-how, consisting of a steady polymer core that has been injected between two metal surfaces.

Approved for everlasting repairs by all main IACS class societies, SPS know-how has been utilized in maritime and offshore purposes for over twenty years – together with for corrosion repairs in ship constructions. Class approvals secured have concerned laboratory testing of the polymer core materials for chemical resistance – together with for methanol. Engineering, Procurement, Construction and Installation (EPCI) service supplier SRC has expertise of advanced refits throughout over 5,000 initiatives worldwide, together with intensive expertise of the patent protected SPS know-how course of.

For the Methanol Superstorage gasoline tank, a 25mm thick steel-polymer-steel barrier supplies safety in opposition to hearth or leakage that’s equal to a standard tank, in line with SRC. The injected polymer additionally creates oxygen-free circumstances behind the metal plates to stop corrosion.

The SPS sandwich panel system can be utilized in lieu of cofferdams on all tank boundaries together with these dealing with to shell plating.

“We always knew how significant Methanol Superstorage would be, because existing ships need to play a full role in energy transition if GHG emission targets are going to be met and storage capacity is a key challenge,” mentioned Hannes Lilp, CEO, SRC Group. “We are already in detailed discussions with a well-known ferry operator, while we’ve been approached by cargo ship operators, offshore support vessel owners, tug companies, shipyards in Europe and Asia, and by the marine engine suppliers. One area that has surprised us has been the high level of interest from the super yacht sector.”

Less shocking has been the circulation of inquiries from cruise ship homeowners, lots of which have already been learning the feasibility of retrofitting ships for methanol as a marine gasoline.

“These are new and confidential discussions, but what I can say is that live projects are under review to accommodate consideration of Methanol Superstorage, while one project that looked dead is being revived,” mentioned Lilp. The in-flow of technical questions from all corners of the maritime trade has been “almost overwhelming.”

“We always knew how significant Methanol Superstorage would be, because existing ships need to play a full role in energy transition if GHG emission targets are going to be met and storage capacity is a key challenge,” mentioned Hannes Lilp, CEO, SRC Group. Image courtesy SRC Group

“We always knew how significant Methanol Superstorage would be, because existing ships need to play a full role in energy transition if GHG emission targets are going to be met and storage capacity is a key challenge,” mentioned Hannes Lilp, CEO, SRC Group. Image courtesy SRC Group

The Path to Classification

Securing AiP supplies a know-how developer with a press release from Class confirming that there aren’t any main obstacles to future certification or classification. Discussions masking approvals from different classification societies are ongoing, mentioned Lilp, though he acknowledges that journey from AiP to full class approval is substantive. In an space the place the laws underlying gasoline storage are evolving, further scrutiny may be anticipated.

“Due to the regulatory status of low flash point fuels all methanol fuelled ships need to go through a Risk Based Certification process that includes full risk assessment for the whole methanol fuel system from bunkering station to the engines,” mentioned Alex Vainokivi, Innovation Manager, SRC Group. “AiP is part of the risk assessment. Any final approval for a methanol fuelled ship comes from the Flag State Administration.”

Nevertheless, key SPS know-how traits are usually not in dispute. “For example, under fire testing, and when the core thickness for SPS structure is more than 25mm it has satisfied the fire safety objectives and the functional requirements of SOLAS A-60 regulations without the need to install thermal insulation,” says Vainokivi.

“We will establish whether inerting and venting are needed on a case-by-case basis – and the same for fire and leakage detection – but the requirements relating to cofferdams can be dispensed with. From that perspective, the solution provides equivalent ‘triple barrier protection’ to prescriptive requirements for cofferdams adjacent to all space categories – including accommodation.”

As of September 2023, methanol had been specified for 216 newbuilds, in line with figures from DNV, and Clarksons estimates that 1,200 ships could possibly be powered by methanol by 2030.

Lilp says probably the most often requested query SRC has been fielding considerations whether or not Methanol Superstorage is as applicable for newbuildings as it’s for retrofits. “The answer is an emphatic yes: fuel storage tanks can be constructed using the SPS sandwich panel system in lieu of cofferdams on both new build and refit projects. We seek to open more direct channels of communication for questions from major shipbuilders and designers worldwide.”