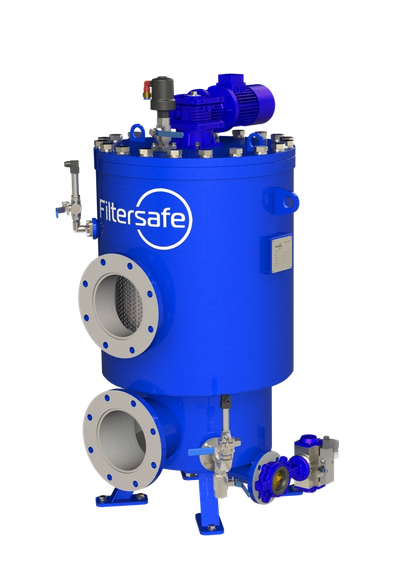

Filtersafe introduced the launch of its brand-new ‘MANTA’ filter collection, especially crafted for UV based ballast water monitoring systems (BWMS).

The high-performance filter has the ability to eliminate 99.6% of microorganisms over 50 μm to guarantee that ship proprietors and also drivers will certainly be certified with the International Maritime Organization’s D-2 criterion for the execution of the ballast water monitoring convention, which have to be followed by 08 September 2024, along with the united state Coast Guard’s (USCG) existing ‘Final Rule for Ballast Water Treatment’.

Filtersafe stated it has actually gotten an equal collection kind authorization from Det Norske Veritas (DNV) and also the USCG, making it among the very first total filter redesigns to be accepted under the USCG’s Policy Letter (CG-OES 03-20) Guidance on Testing Alternate Components for a Type Approved BWMS.

The MANTA functions Filtersafe’s brand-new one-motion scanner. This brand-new style eliminates side activity of the scanner, lowering expense and also getting rid of components. It includes a bigger closeness nozzle which has the ability to clean up the filter display in one continual activity. When integrated with the filter’s unpleated display, the MANTA has actually enhanced cleansing protection that gets to 100% of the display, according to the producer.

The filter additionally includes scalable automated self-cleaning. Automatic filter cleansing can be raised when ballasting in sediment-rich waters, consisting of those located in the port of Shanghai, to guarantee a regular circulation price and also to stay clear of pricey functional problems such as blocking. Despite being examined with a better mesh filter, the MANTA exceeded the initial Ballast Safe style in independent screening of the cleansing, elimination price, and also throughput performance of the filters, Filtersafe stated.

For rust avoidance, Filtersafe presented 904L stainless-steel throughout its filter display supply chain in 2014 and also this remarkable steel is additionally made use of in the MANTA collection’ sintered displays. In enhancement, and also in order to fight the steady-rising expense of alloy product, Filtersafe, along with its companions, has actually embraced a brand-new SuperQuenching treatment, obtained from the room market, to get rid of the product deterioration of 316L as a result of the weaving, sintering, and also construction procedure. This enables it to additionally supply a feasible 316L display choice at a reduced expense. Improved long life and also remarkable cleansing lowers upkeep expenses and also, also when upkeep is called for, MANTA is attentively developed to guarantee it can securely and also effectively be preserved by a single person.

Mark Riggio, Head of Marine at Filtersafe, stated, “As requested by leading BWMS manufacturers, we’re pleased to offer Filtersafe performance in a smaller package, designed specifically for UV systems. Having equivalent series type approval already completed makes adopting a MANTA filter a no brainer for our current customers. The rising challenges posed by sediment-rich water conditions are not going away – and now we have the filter that anyone can use to meet them.”

“From a shipowner and operators’ perspective, MANTA is a win in both the CAPEX and OPEX categories. You expect CAPEX costs may be a little more for a high-quality filter, MANTA disrupts that. And our OPEX costs have always been Filtersafe’s strong point.”