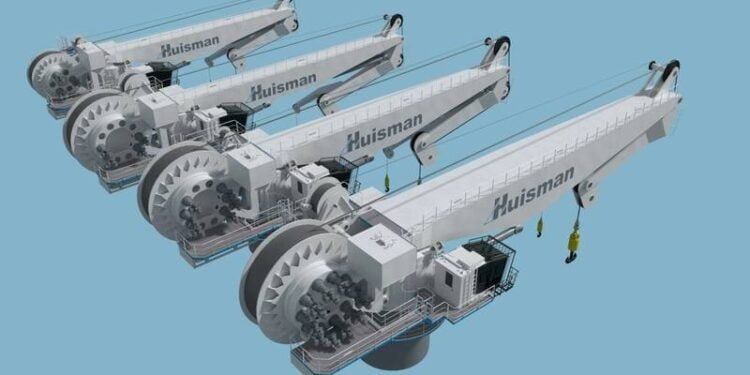

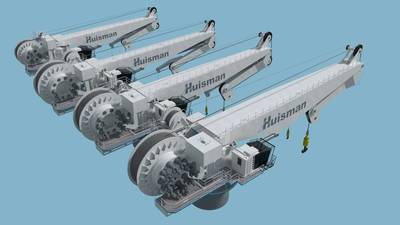

Dutch offshore crane maker Huisman launched a renewed collection of subsea Knuckle Boom Cranes for the use within the offshore subsea development market.

“With this new series, the company’s portfolio has been adapted to the latest trends in offshore construction vessels with respect to energy efficiency, automation, and safety,” Huisman mentioned.

According to Huisman, the brand new, collection consists of fashions ranging from 85mt as much as 350mt and canopy each setups with a winch under deck in addition to on the again of the crane.

Water depths as much as 3,000m are included as commonplace, whereas deeper water capabilities could be offered as an choice. Furthermore, Huisman mentioned its patented Fiber Rope resolution could be provided as an choice on a number of fashions of the vary to extend the lifting capability at depth.

“The Knuckle Boom Cranes come with the most recent version of Huisman’s Secondary Controlled Electro-hydraulic power system as standard. The origin of this secondary controlled system dates to the 1980s when Huisman pioneered application of such equipment in offshore cranes. Huisman has recently implemented the fifth generation of its motion controller “HMC 05c” in all of these models. This provides crane operators with the most responsive and accurate system on the market. With the latest improvements, interaction with the vessel’s power grid has been improved to allow for use with alternative fuels, including ammonia, methanol, or LNG,” Huisman added.Credit: Huisman

Huisman additionally mentioned it might provide all cranes on this collection geared up with Full Electric Active Heave Compensation (AHC). Credit: Huisman

Credit: Huisman

“With today’s focus on high-performance, high-capacity energy storage systems in offshore construction vessels, interaction with full electric AHC and large-scale energy regeneration has become much more realistic in recent years,” Huisman mentioned.

Also, Huisman mentioned that it was addressing the necessity of in the present day’s offshore crane market the place there’s a rising deal with lifts from one vessel to a different.

“To address this need, Huisman has introduced a new feature: relative heave compensation. This innovation allows for compensation not only for the motion of the crane vessel but also for the motion of the other supply vessel. Motion detection for the supply vessel is achieved through a remote motion reference unit, which transmits the signal wirelessly to the Huisman offshore crane. This setup has already been integrated into several offshore cranes and is also available as a retrofit upgrade for existing Huisman cranes,” Huisman added.

“For sizes of 400mt and beyond, Huisman has a portfolio of full electric Hybrid Boom Cranes available, including subsea crane models delivered with a capacity of 1,000mt. The series of cranes is optimised for high reliability, ease of maintenance and short delivery times from Huisman’s facilities in both Europe and Asia,” Huisman added.

Cees van Veluw, Product Director Cranes at Huisman: “With the update of our Subsea Knuckle Boom Crane series, we respond to the market need for technical improvements on existing products. Vessel owners have more and more interest in aiming for zero emissions on their newbuild vessels. Also, battery banks on vessels are not only used for “spinning reserve” anymore, however can serve a number of roles on the vessel, all centered on utilizing the vitality extra effectively.”