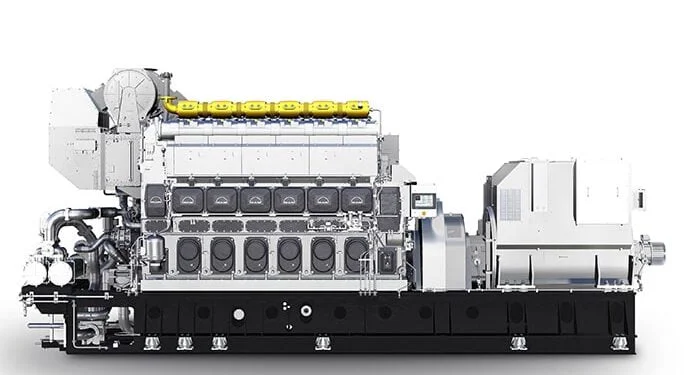

The MAN 35/44DF CD auxiliary engine

MAN Energy Solutions has launched its newest engine, an MAN 35/44DF CD auxiliary engine kind. Developed in cooperation with Korea’s STX Engine and solely for manufacturing by MAN licensees, the brand new engine is especially geared toward containership and LNG service purposes.

The genset was developed with the clear purpose of chopping down CAPEX and OPEX prices and to be future-proof for many years to come back. It relies on the mature and confirmed MAN 35/44DF CR and MAN 32/44CR engines. Used in a large number of purposes over a few years and with tens of millions of operating hours, they type the premise for the brand new engine’s operational security and low upkeep necessities.

The 35/44DF CD incorporate a lot of options for lowering greenhouse gasoline emissions, comparable to methane slip, which it reduces by as much as 85% in contrast with market requirements.

MAN Energy Solutions says that it expects the primary supply of the brand new auxiliary engine by mid-2024, with the primary unit beginning business operation from 2025.

“We specifically developed the MAN 35/44DF CD in close collaboration with STX Engine to optimize the requirements of an auxiliary engine,” stated Sephardim Koblenz, head of licensing at MAN ES. ”Among different traits, each shipyards and shipowners drastically admire auxiliary engines which can be simply put in and maintained, whereas reliability and cost-optimization are additionally key.”

METHANOL READY

“A major advantage of the 35/44DF CD, besides its powerful output, is its focus on cutting methane slip and positioning itself as future-fuel ready,” stated Alexander Knafl, head of R&D engineering, four-stroke at MAN ES “This includes being ready for dual-fuel methanol operation by 2026.”

The MAN 35/44DF CD is characterised by:

- CAPEX/OPEX-optimized design;

- straightforward integration by shipyards, low engine-room funding;

- full digitalization and connectivity with state-of-the-art cyber safety;

- methane-slip discount know-how as customary, delivering as much as 85% decrease methane slip in comparison with market requirements;

- compact footprint with a number of format choices for engine-room flexibility;

- highest energy output in phase with 560 kW/cylinder; resulting in fewer cylinders and even engines for similar energy output per vessel

- gasoline flexibility, together with biofuels, gasoline and in addition future-fuel methanol-ready.