MacGregor, a part of Cargotec, has launched a brand new and augmented gravity self-unloading system that it says will enable bulk carriers to ship a greater variety of cargo, in better quantity.

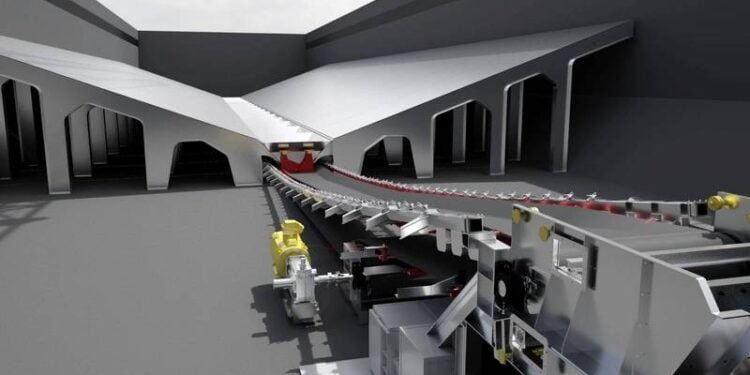

The new system, the MacGregor GravityVibe, deploys a patent-pending vibrating unloader to cut back inside friction and ease the discharge of coarse supplies similar to wooden chips from the cargo maintain.

While the automated unloading sequence stays a gravity-based operation, the MacGregor system contains vibrating panels to shift the remnants or break the ‘bridges’ that kind when coarse materials sticks collectively to dam the outlet.

The vibrating panels are remoted from the hull construction – utilizing an answer from MacGregor on which a patent is pending – to reduce the switch of vibrations and noise to different elements of the vessel.

In distinction with an ordinary gravity self-unloading configuration, the place slope angles vary from 35 to 60 levels relying on the fabric, the brand new MacGregor system can discharge numerous cargo varieties with slope angles of simply 15–20 levels. Since steep slope angles restrict maintain quantity, the system subsequently will increase not solely the number of cargo varieties a vessel can deal with but additionally its cargo capability. The further capability additionally interprets into decrease carbon dioxide emissions per carried tonne of cargo.

Whereas giant sized standard self-unloaders function two longitudinal and two switch conveyors, the MacGregor GravityVibe’s low slope angles additionally imply that it capabilities with only one longitudinal conveyor. With fewer elements put in, the required upkeep and spare-parts might be low in comparison with standard self-unloading programs. The streamlined set-up additionally minimises spillage and the necessity for cleansing, that means much less work and improved security for crew.