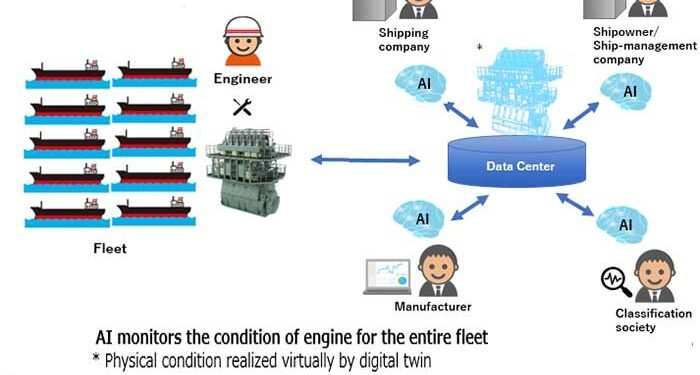

Ultimate goal is a sophisticated CBM where AI keeps track of equipment problem for whole fleet

Japan’s NYK Group has actually gotten to joint research study arrangements targeted at establishing innovative condition-based upkeep (CBM) monitoring procedures for ship equipment, and also has actually begun confirmation of information throughout real ship procedures.

Machinery plant information from several sensing units will certainly be shared and also kept an eye on with the category culture and also equipment makers in actual time.

NYK Group intends to utilize this information and also real-time surveillance to create a sophisticated CBM for usage in manned self-governing vessels. These will certainly utilize innovative innovations and also remote assistance from the office to sustain ship procedures and also improve security.

.

Currently, the delivery market normally utilizes time-based upkeep (TBM). This calls for a vessel to stop procedures for a couple of weeks of assessments every 2 or 3 years, also if no tiredness or break down of the engine is observed. In enhancement, unanticipated failings can take place throughout trips and also create lengthy hold-ups.

Recent growths in info and also interaction innovation imply that big quantities of information can be sent in between ship and also coast. The NYK Group has actually made use of these developments to concentrate on CBM and also to perform research study on optimum upkeep. It has actually currently made a decision to enhance its research study by partnering with the Monohakobi Technology Institute (MTI), ClassNK and also equipment makers– Japan Engine Corporation when it comes to engines and also Mitsubishi Heavy Industries Marine Machinery & & Equipment Co when it comes to heavy steam generators.

DETAIL OF JOINT STUDY

Ships will certainly be mounted with SIMS2 (an info monitoring system established by NYK and also MTI that permits data-sharing amongst offices ashore and also mixed-up in actual time) plus a brand-new sensing unit and also tools in 2 various kinds of major engine and also major heavy steam wind turbine. Detailed functional information such as resonance and also temperature level of bearing will certainly be gathered. The problem of the engine will certainly after that be shared and also continuously kept an eye on by the category culture and also engine makers.

The job will certainly likewise function to make forecasts of equipment failing and also continuing to be helpful life (RUL) by making use of supplier competence to develop optimum CBM standards and also to after that confirm them on real ships.

These outcomes will certainly be shown to the category culture to develop a brand-new category study system based upon CBM.

In the future, NYK intends to create advanced CBM that makes it possible for constant surveillance of the problem with AI (expert system), and after that realizeof additional optimum upkeep by integrating info such as functional timetables.

NYK claims developing a sophisticated CBM system is an action towards an extremely automated vessel, and also hence an independent one.