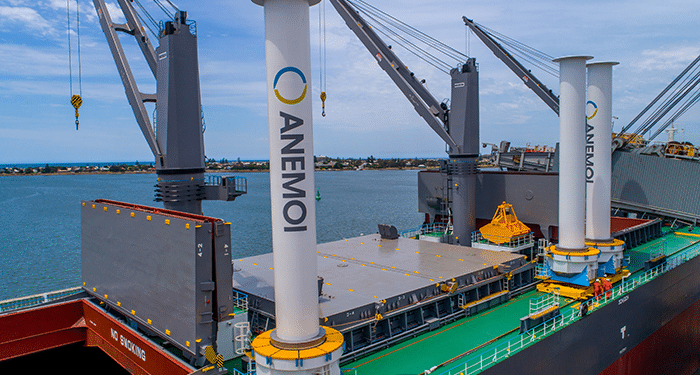

Credit: Anemoi

By Nick Contopoulos, COO, Anemoi

As a renewable supply of vitality, wind is now a compelling choice for shipowners.

Rotor sails have been first put in on a vessel over 100 years in the past. But by means of analysis, innovation and meticulous improvement Anemoi engineers have re-imagined the expertise for contemporary use.

An aerodynamic phenomenon, often called the “Magnus Effect,” is essential. As the cylinder rotates inside an airflow, a ahead thrust drive perpendicular to the obvious wind path is created, which delivers extra thrust to the vessel. The thrust generated can both present extra vessel velocity or preserve vessel velocity by decreasing energy from the principle engine. The rotor sails, that are tall and cylindrical, might be put in on the principle deck, bow or elsewhere with ample house.

Many forward-thinking homeowners and charters are turning to wind to handle vessel emissions. Anemoi is engaged on numerous tasks for supply in 2023 and onwards. These tasks are for bulk carriers starting from 82k DWT to 388k DWT with three to 5 rotor sails per vessel. Due to the character of every of the vessel’s operations, cargo dealing with and air draft necessities, each vessel has chosen to pick a deployment system for his or her rotor sails. On some vessels Rotor Sails will probably be put in on Anemoi’s distinctive rail system, which permits the sails to maneuver alongside or throughout the deck. On different vessels, folding Rotor Sails are being put in, which allows the sails to be lowered from the vertical.

In November final yr, Anemoi reached an settlement with COSCO Shipping Heavy Industry Co. (CHI), one in every of China’s main shipbuilding organizations. CHI has quite a few yards able to as much as 7.5m dwt annual manufacturing throughout all main vessel segments and a major international buyer base.

CHI clients will now have the choice to put in Anemoi rotor sails on newbuild vessels or retrofit throughout dry dock. Under the phrases of the settlement, the businesses can provide a turnkey set up answer to clients.

CHI share a long-term imaginative and prescient of the position that wind assisted expertise can present in delivering emission discount. Anemoi are planning a extremely profitable co-operation within the years to come back and are already lining up the primary turnkey set up alternatives.

Optimal efficiency and automation

The Anemoi rotor sail system is comprised of the rotor sail itself, the muse, deployment system (if required), wind sensors and electrical, management, and automation techniques. The major parts of our rotor sails are the “rotor” (the cylindrical, rotating half), the help tower, higher and decrease bearings, and {the electrical} drive system.

The rotor is constructed from superior light-weight composite materials and the tower is a metal column construction. We use these supplies to make sure most efficiency of our rotor sails and to face up to all climate situations.

The rotor sails have a management station positioned on the bridge. This routinely controls the velocity and path of the rotor sails, in addition to monitoring the efficiency and standing of the system. Our management system is designed to maximise efficiency and reduce crew enter with automated velocity and path setting, tools monitoring, security options and efficiency

reporting to stakeholders utilizing a ship to shore knowledge transmission.

Future proof

Getting to zero emission transport will probably be a significant problem. However, with rising applied sciences like rotor sails changing into broadly accessible and adopted out there, wind can provide an answer to vitality effectivity within the brief, medium and long-term for each newbuild and retrofit. As different eco-technologies, energy-saving gadgets and different fuels turn into market prepared, these can be utilized together with auxiliary wind propulsion to attain enhanced environmental advantages.