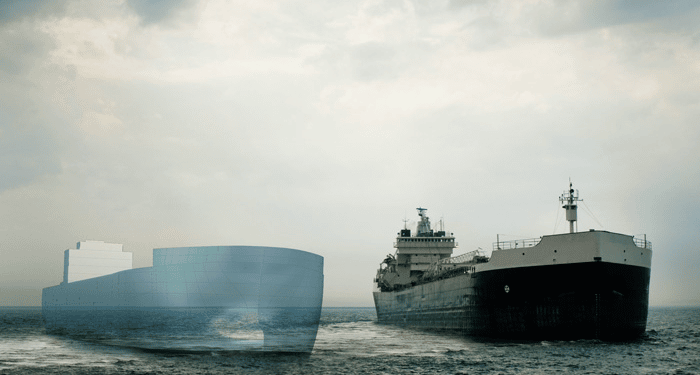

Ghost bulker. (Credit: NAPA)

Data is creating a brand new bridge between ship design and operation, one that may assist construct safer, extra sustainable ships sooner or later, says NAPA CEO Mikko Kuosa.

The sustainable ships of the long run will probably be made of knowledge simply as a lot as metal, they usually would be the results of a collaboration that ranges from shipyards to class societies, to shipowners, operators, charterers, cargo house owners and extra.

NAPA’s digital 3D fashions are already in use by designers and shipyards worldwide, and more and more, they’re serving to shipowners, operators and managers to scale back danger and optimize operations at sea. Now, the circle is being closed as real-life operational knowledge is being fed again to shipyards to assist them perceive how their designs behave at sea. Real-life voyage knowledge hyperlinks principle and follow, offering shipyards with the unparalleled capability to research their vessels as soon as they’ve been deployed at sea, and from there to refine the designs of future ships.

At the center of this digital transformation is the popularity that no two ships are precisely the identical, and even twin vessels can carry out in another way relying on their operational profile. As this range will increase with the arrival of different fuels and clear applied sciences, understanding the specifics of every ship will probably be much more vital. By utilizing the identical 3D fashions and data all through the design and operation of a vessel, we are able to profit from every asset and speed up the sustainability journey of the trade as an entire.

For instance, the usage of digital twin knowledge can take voyage optimization to increased ranges. NAPA’s Stability ensures the secure and optimum planning of stowage, cargo and ballast to optimize the ship’s trim, thereby lowering gas consumption. NAPA Voyage Optimization combines ship-specific digital fashions, operational knowledge generated by programs on board, and real-time data on climate and sea routes, to mannequin ship efficiency. Together these allow captains to decide on the perfect and most secure routes to reduce gas consumption and emissions—lowering each by round 5-15%.

Combining knowledge from AIS climate companies and loading situation historical past, NAPA can assess the severity of the ocean situations skilled by a particular vessel, the extent of hull fatigue, and estimate the probability of cracks and different issues showing. In circumstances when the ship has not skilled very harsh situations, this may give the inexperienced mild to increase the hull lifetime.

This similar strategy to 3D modelling can even facilitate security inspections. Ships are made from over 200,000 items of metal, and it might be too time consuming to examine all of those manually throughout a typical inspection. Digital twins can spotlight particular areas of curiosity—predicting the place hull fatigue is almost definitely to happen, enabling inspectors to establish and prioritize the highest-risk areas.

Efficiency, stability and security knowledge will probably be intrinsically linked going ahead. Highly linked ships allow a extra proactive strategy to security, the place dangers to stability—from routes and climate situations to the variety of doorways left open—are continuously monitored. Using the identical 3D fashions as we do on the design stage, our stability calculations happen in actual time, so any points could be flagged to the crew and addressed earlier than they escalate. Moreover, in emergencies, response groups can entry the identical stability knowledge because the crew by way of the digital twin to make important calculations in actual time.

It is important that every one stakeholders cooperate on data sharing to speed up the event of designs and operational patterns that may meet society’s wants for a cleaner ocean and better sustainability. Having entry to 3D fashions will play a significant function, and that’s why I say that the ships of the long run will probably be made of knowledge, metal, and a collaborative spirit. They can have knowledge at their core all through their lifecycle to maximise effectivity, security and sustainability.