Two load-bearing columns of Norway’s leading maritime market collection in Sunm øre on the nation’s west shore– overseas power and also the exploration cruise ship field– took extreme knocks from diving power costs in the 2010s complied with by COVID-19. However, a current excursion of the area located the collection in recuperation setting.

At the moment, the collection’s diversity method was to study the arising exploration cruise ship field: tiny, very advanced ships developed to run in a few of the globe’s most delicate settings included functions consisting of the greatest ice-class, most recent waste warm recuperation systems, and also a few of the cleanest-burning engines. The expectation was appealing, till COVID-19 brought the international cruise ship market to its knees.

But equally as the collection relocated quickly from mostly an angling economic climate right into overseas power in the 1970s, its method of active diversity proceeds. Today, tank farming is growing and also brand-new campaigns guarantee quick growth in the overseas wind field.

“Oil and gas rates… are going up quite far,” claimed Daniel Garden, chief executive officer of collection supervisor GCE Blue Maritime, in analyzing the present circumstance. “Now, all those laid-up PSVs have work again.”

He includes that although “there is a lag to get customers back to planning their holidays, it looks like [expedition cruise] vessels are back in operation, too. Not all are fully booked … but the newbuild program has started again”.

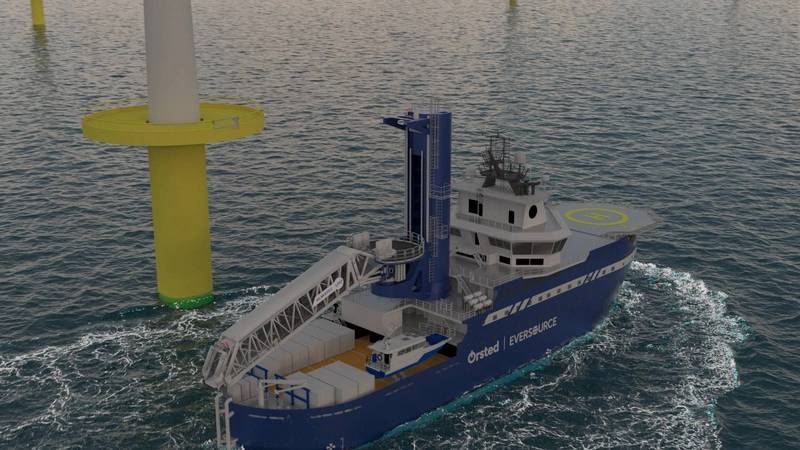

And also if Norway does not have much usage for brand-new windfarm assistance vessels (SOVs) with nearly no generators in position itself, installers and also programmers throughout Europe have immediate demands and also Norway’s eye-catching export credit report plans offer an important reward. Here’s a stumping of business in the location.

Norwind Offshore took distribution of Norwind Breeze previously this year. Credit: Norwind OffshoreNorwind Offshore

Norwind Offshore took distribution of Norwind Breeze previously this year. Credit: Norwind OffshoreNorwind Offshore

Start- up Norwind Offshore is an intriguing study. Established throughout the pandemic, it is a partnership in between overseas professionals Volstad, Farstad and alsoKleven Later, Danish mutual fund Navigare Capital Partners signed up with the celebration.

Norwind’s initial strategy had actually been to transform laid-up PSVs right into SOVs, however spiralling power costs placed paid to that. “There are now zero PSVs in layup,” claimed Svein Leon Aure, Norwind CHIEF EXECUTIVE OFFICER. “Secondhand prices for PSVs have increased 50%, so we cannot get hold of cheap ones to convert – it would cost close to a newbuild.”

So, Norwind is running simply one transformed PSV– Norwind Breeze, developed as Skandi Responder in 2015. Aure does not seem shedding rest, nevertheless; his business is showing a desire, in accordance with others in the West Coast collection, to worth neighborhood shipbuilding knowledge.

The Norwind Breeze conversion establishes a crucial training course for the future. Underdeck mud and also slop containers are currently open areas which might house financial institutions of batteries. With normal Norwegian resourcefulness, Norwind wishes to furnish its vessels with innovation comparable to coast power, however, for linking into wind generators. Aure states it might be feasible to power all SOV procedures by doing this, making use of 100% battery power, in future, making overseas procedures totally carbon-free.Norwind is intending a collection of brand-new SOVs. With this method, the business has actually appointed close-by shipyard team, Vard.

Battery pleasant: the DC set up aboard an ESS-equipped VARD vessel. Image politeness Vard

Battery pleasant: the DC set up aboard an ESS-equipped VARD vessel. Image politeness Vard

Vard

The shipbuilder’s style resourcefulness is clear to see in its most recent SOV forNorwind New solution vessels are being established to make use of overseas wind power, with hulls developed to optimize hull characteristics outside while optimizing inner room for financial institutions of batteries, discussed Vard’s Research & &Innovation Manager Henrik Burvang

In truth, some 87% of Vard’s present orderbook– with building and construction split in between Romania and also Norway– will certainly either be geared up with, or ‘ready’ for, big financial institutions of batteries. Close to half of engines will certainly be developed to make use of different gas like ammonia or methanol. These advancements become part of Vard’s “Zeroclass,” vessels which are developed to run within a zero-carbon standard. Currently, Zeroclass includes an angling vessel, a PSV, and also an SOV style, however a lot more get on the method.

Image politeness WavefoilWavefoil

Image politeness WavefoilWavefoil

The current buzz over wind-assisted ship propulsion has actually been tough to overlook. But one budding Norwegian business has actually developed a completely various methods of obtaining ship power from the climate. The method chief executive officer Bente Storhaug Dahl describes the innovation is this. “Imagine you are trying to push a plank of wood down in the water, and it will spring back up. Now, imagine you angle the plank slightly forward, and you will see, the plank will spring up and forward.”

To this end, Wavefoil has actually developed a brand-new bow-mounted system of twin-foils, which fold up out and also when not being used. Rather than offer added drag, as if anticipated, when the waves are high, the aluminum foils can do 2 extremely substantial features on a ship. Firstly, they can contribute to the vessel’s security, decreasing slamming and also spreading out propulsion lots, however they can likewise obtain propulsive power from the waves themselves, creating a gas conserving of as much as 15%.

The system is perfect for smaller sized vessels such as ferryboats and also numerous kind of workboats, especially when running in high sea problems. It is very easy to see where Wavefoil might function well in a Norwegian offshore context.

Norway- based gangway distributor Ulmatec has actually protected an agreement for the supply of a 32-meter movement made up gangway and also logistics support group for ECO Edison, the very first U.S.-built Jones Act solution procedure vessel (SOV). Image politeness Ulmatec

Norway- based gangway distributor Ulmatec has actually protected an agreement for the supply of a 32-meter movement made up gangway and also logistics support group for ECO Edison, the very first U.S.-built Jones Act solution procedure vessel (SOV). Image politeness Ulmatec

Ulmatec Handling Systems

Offshore deck tools supplier, Ulmatec Handling Systems, is currently hectic structure energetic heave-compensated gangway systems for the abundance of SOVs unfinished at neighborhood backyards. Visitors to the Ulmatec center will certainly be captivated to see an enforcing tower framework on the tarmac, made use of to examine brand-new gangway styles.

The goal is for walk-to-work gangway systems to offer various other corresponding objectives too. For instance, the business is establishing telescoping gangways which can likewise act as cranes, along with real estate extendable hose pipes, pipelines and also conveyors to move fluids and also pallets to the wind turbine system.

About 2 thirds of Ulmatec’s company is export, as it is providing the new age of overseas wind building and construction vessels which are offering the new United States market. Though it specifies that the hull should be stocked a United States shipyard, the Jones Act does not avoid Norwegian vendors from gearing up the vessels.

Meanwhile, points are warming up for one more Ulmatec department,Thermal Solutions Vessels can make much better use their waste warm, which consists of engine coat water, exhaust gas warm, and also various other resources. Around 60% of the material of gas is thrown away in an interior burning engine (ICE), claimed Bernt-Aage Ulstein, CHIEF EXECUTIVE OFFICER of Ulmatec Pyro AS, which implies that to make ships a lot more reliable, that warm ought to be re-used for various other objectives on the ship.

It is a future-proof company. “The electro-fuels, ammonia and methanol, will burn with less thermal efficiency than diesel and LNG do now,” Ulstein discussed. “So it will be even more pressing to look at this.”

Bon trip: a making of the experience cruise ship idea, Sif, and also its “refueller”, the thorium-poweredThor Image politeness Ulstein InternationalUlstein

Bon trip: a making of the experience cruise ship idea, Sif, and also its “refueller”, the thorium-poweredThor Image politeness Ulstein InternationalUlstein

Family- had shipyard Ulstein is no simple neighborhood tale, with its vaunted and also right away identifiable X-Bow having actually penetrated the overseas and also workboat fleet everywhere. But the business’s brand-new chief executive officer, Cathrine Kristiseter Marti, confesses that the lawn has actually come with some bumpy rides.

“We started to see light at the end of the tunnel at the beginning of 2020, and then COVID hit — so no more cruise!” she says. “It is a buyer’s market. For us, it’s been quite the restructuring … we still deliver the same, but we are working with fewer people – 840 down to 400. Still, people rally together, and it is wonderful to see.”

The yard’s latest vessels are for Olympic Offshore, with two ships delivered early in July. Specialist vessels such as cable layers are a good fit for Ulstein, since they require in-depth technical knowledge not easy to replicate elsewhere.

Norwegian labour costs are unavoidably more expensive than in Asia or Turkey, but there are more benefits to think about, she explains, including being able to put new ships together at very low embodied carbon cost. “Norwegian shipyards operate on 100% hydropower… we think that should be valued.”

Meanwhile, Ulstein is excited about its latest project – Thor. It is a proposal for an offshore nuclear energy provider to feed SOVs or expedition cruise ships using molten salt reactor technology based on thorium.

Abundant in Norway, thorium could be used to power zero-carbon SOV operations or for battery-powered exploration cruise ships, enabling offshore charging in remote locations. Marti insists this is a change of pace for nuclear. “We will not be working with uranium, or other nuclear materials which can be turned into weaponry,” she said. “Ulstein is committing to that. That is why we are talking about thorium.”

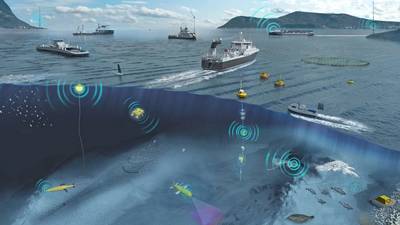

Kongsberg Maritime

The drive to cut carbon emissions in ship construction is a key driver in Kongsberg’s R&D into additive manufacturing in metal, something which has eluded the industry so far. A consortium including Kongsberg, DNV, and several additive manufacturing specialists believe they have developed a new process, wire arc additive manufacturing (WAAM), which can make parts stronger than ever before.

There are two technologies for this, MIG welding and plasma, both of which Kongsberg tested. The new part is a crank disc, which must be built to extremely high specifications. Kongsberg’s Mette Lokna Nedreberg, Manager of Material Technology, says that as well as potentially replacing costly and CO2-intensive traditional manufacturing processes, additive-manufactured parts fill a new niche, as well, in creating spare parts for deprecated machinery for which OEMs have ceased support.

“We very often have to buy new parts for our customers, and we wanted to see if we could 3D-print these,” said Ms. Lokna Nedreberg. “[Forging] uses a lot of energy and has very long lead times. But if the vessel is waiting for a component, they need it immediately.”

Meanwhile Kongsberg is continuing with the development of its permanent magnet rim drive thrusters, which can be used either as tunnel thrusters or for a steerable azimuth thruster.

Photo credit report: NTNUScanreach & &(* )overseas business with an agnostic method to overseas renewables and also oil & & gas, Olympic Subsea

Photo credit report: NTNUScanreach & &(* )overseas business with an agnostic method to overseas renewables and also oil & & gas, Olympic Subsea

Another Norwegian has actually been working with generators both over and also listed below the waterline. Olympic Subsea generators are a specific niche market, however numerous experiments are underway on the eastern shore of Tidal, along with Scotland and alsoFrance Japan plentiful electric power to be collected, one point holding the innovation back is the upkeep obstacles. Despite describes “We have to use a 250-ton crane, and there is a very narrow operational window, when the currents are low,”, COO ofMarius Bergseth Olympic Subsea.