Thordon Bearings has actually gotten a Canadian Coast Guard agreement to provide 6 SeaThigor shaft seals for retrofit installments on 3 icebreakers.

The 5,910 grt CCGS Pierre Radisson as well as sibling ships CCGS Amundsen as well as CCGS Des Groseilliers, will certainly each be retrofitted with 2 SeaThigor ahead seals throughout set up drydockings over the following year.

The order adheres to the success of the 2017 setup as well as succeeding procedure of SeaThigor seals aboard the oceanographic as well as hydrographic study vessel CCGS Hudson.

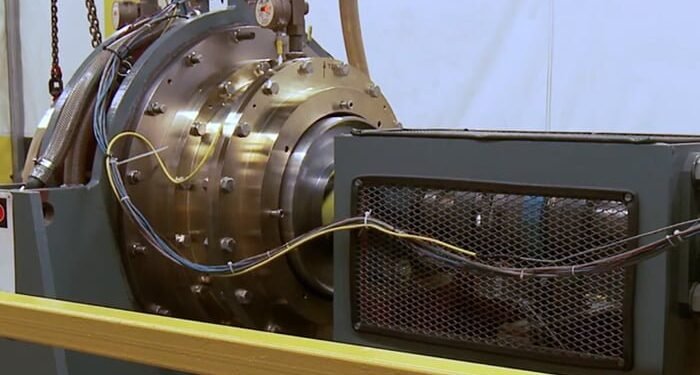

Scott Groves, Thordon Bearings’ Regional Manager– Americas, claimed: “This is a significant order for Thordon Bearings, marking not only the SeaThigor seal’s first-ever reference onboard a purpose-built icebreaker but also the largest propeller shaft seals we have ever manufactured.”

The 98.2 m (322 feet) long, 1200-class vessels are developed to Arctic Class 3 demands as well as run with twin 674 mm (26.5 in) size shafts driving repaired pitch props. Propulsive power is produced by 6 Alco M251F major engines supplying 10,142 kW of power.

“The vessels’ existing seals were leaking water into the machinery spaces, which meant they could not discharge oily-water overboard into Arctic waters,” kept in mindGroves “Ultimately, CCG needed a seal solution that was robust enough to withstand heavy-duty ice-breaking operations, without leaking. SeaThigor provides that level of robustness.”

The seals provided to the Pierre Radisson- course of ships will certainly likewise be the very first SeaThigors developed with a split covering

“The limited space available in the vessels’ engine room prevented the installation of a SeaThigor seal with a conventional, fully encased bronze housing,” claimed Carl Sykes, Manager of Thordon’s Global Service & & Support department. “We designed a seal with a split casing to simplify the installation and commissioning process, allowing engineers to access the underside of the seal. Many different departments – procurement, design, engineering and manufacturing – came together to really make this happen. It was a complete team effort.”

Jasmin Racicot from Thordon’s Quebec- based representative RMH Industries, included: “What interested CCG about the SeaThigor was the seal’s emergency safe-return-to-port function and low maintenance requirement; the silicon carbide faces are designed for reduced wear and tear throughout its operational life, resulting in improved life cycle costs for the Coast Guard.”

CCG is an enduring consumer of both Thordon Bearings as well as RMH, with a variety of vessels running Thordon’s salt water lubed Compac bearing system.

One of the very first CCG vessels to gain from Compac was the 6,098 gt CCGS Des Groseilliers, which was mounted with the system 17-years-ago. It will certainly be fitted with a SeaThigor seal at a set up drydocking in 2020. CCGS Amundsen will certainly be transformed to Compac at its following drydocking, when the SeaThigor seals will certainly likewise be mounted.